Alumina Granules play a crucial role in various industrial applications. As industries continue to demand high-performance materials, the significance of Alumina Granules only grows. According to a recent report by MarketsandMarkets, the alumina market is projected to reach $37.4 billion by 2026, primarily driven by its increasing use in ceramics, refractories, and metallurgy.

Dr. Emily Carter, an expert in materials science, remarks, "Alumina Granules are essential for enhancing the durability and efficiency of industrial processes." This statement highlights the pivotal function these granules serve in applications from aluminum production to advanced ceramics. Companies are increasingly seeking granular solutions to improve their product performance.

Despite the overwhelming advantages, some industries still overlook the potential of Alumina Granules. Many operators fail to optimize their processes, leading to subpar results. A deeper understanding of application techniques and proper granule selection can significantly enhance performance. Hence, focusing on effective methods of utilizing Alumina Granules could yield substantial improvements in efficiency and output for various sectors.

Alumina granules are increasingly popular in various industries. Composed primarily of aluminum oxide, they possess unique properties that make them versatile. These granules have high thermal stability, impressive hardness, and excellent chemical resistance. According to industry reports, the global demand for alumina is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2028.

In industrial applications, alumina granules serve multiple roles. They are often used as abrasive materials in manufacturing processes. This is due to their hardness, which is second only to diamonds. Additionally, these granules are pivotal in catalysis and filtration systems. Their porous structure enhances reaction efficiency and improves purification processes. However, users sometimes underestimate the importance of particle size in specific applications. Smaller granules may offer better surface area but can lead to increased dust formation.

While the benefits are evident, there are challenges in using alumina granules effectively. One significant issue is their tendency to agglomerate. This can impede their functionality in certain applications. Another consideration is the environmental impact of alumina production, which can lead to significant waste. Efforts must be made to refine processes and minimize ecological footprints. Industry innovation is needed to address these challenges while capitalizing on the numerous advantages alumina granules provide.

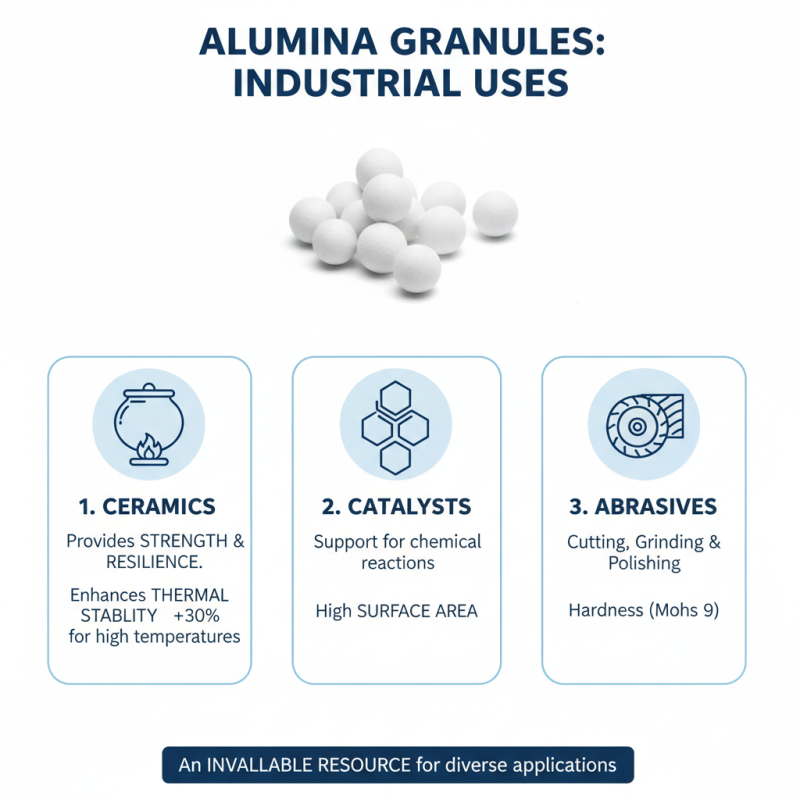

Alumina granules serve multiple industrial purposes, making them an invaluable resource. They are commonly used in ceramics, catalysts, and abrasives. In the ceramics industry, alumina provides strength and resilience. Reports indicate that alumina can improve the material's thermal stability by up to 30%. This is crucial for high-temperature applications.

In the catalyst sector, alumina granules enhance the effectiveness of catalytic reactions. They act as a support material, helping to achieve higher reaction rates. Additionally, the granules can increase the surface area for reactions, thereby boosting performance by about 25% in certain processes.

**Tips:** Always consider the particle size for optimal results. Larger granules may not fit all applications. Regularly review the sourcing and quality of alumina. Impurities can lead to reduced efficiency. Address these factors before implementing alumina in your processes. Quality control is necessary for success, as each granule plays an important role.

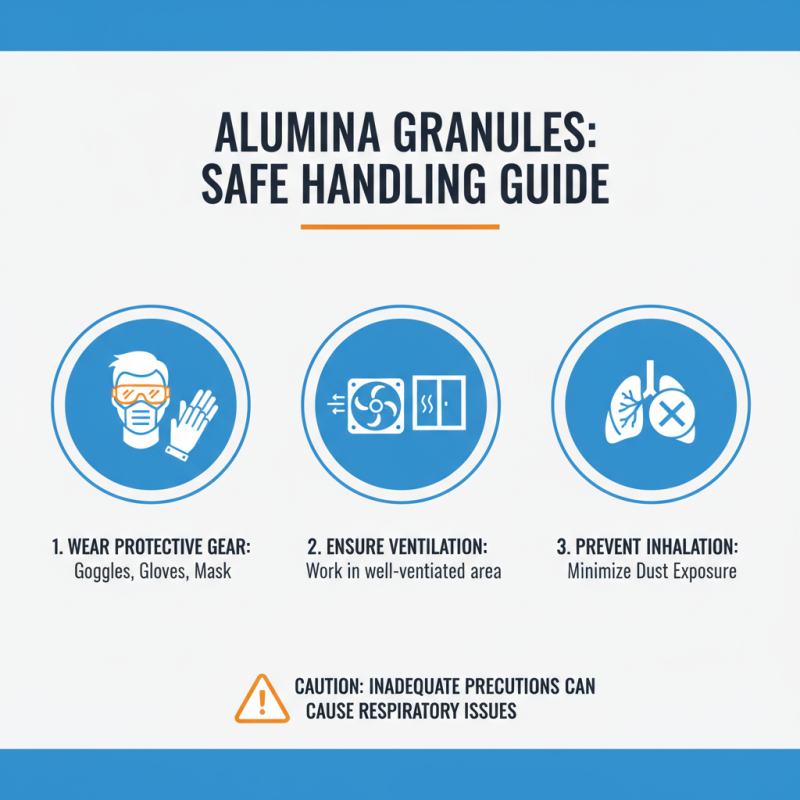

When working with alumina granules, proper preparation and handling are crucial. First, wear appropriate protective gear. Safety goggles, gloves, and masks can prevent exposure to dust. Always work in a well-ventilated area to minimize inhalation risks. Inadequate precautions might lead to respiratory issues.

Transporting alumina granules requires careful consideration. Use suitable containers to avoid spills. Spills can create messy situations. Ensure that the granules are secured during transportation. It's easy to overlook, but even small leaks can be wasteful.

**Tips:** Regularly check equipment for leaks. Keep the work area clean to reduce hazards. Efficient handling starts with organization. Label containers clearly to avoid mistakes. Improper handling can lead to contamination, affecting product quality. Taking these precautions will ensure a smoother process in using alumina granules effectively.

Alumina granules are widely used in various industrial applications due to their unique properties. They serve as an essential component in materials like ceramics, refractories, and abrasives. To maximize their effectiveness, it's crucial to adhere to best practices for usage.

One vital tip is to ensure proper storage. Humidity can impact alumina's performance. Store granules in airtight containers to prevent moisture absorption. Testing the granules on a small scale before large-scale application can save time and resources.

Another important aspect is to understand the correct mixing ratios. Too little or too much can lead to performance issues. Conducting trials helps in determining the ideal blend for your specific needs. Consider environmental factors, as they can influence the behavior of alumina in the application.

Additionally, keep in mind that alumina can be abrasive. Use appropriate safety gear while handling. Identifying the right application method is also essential. Some methods may lead to uneven distribution, affecting the final product's quality. Being aware of these nuances will guide you in optimizing your industrial processes.

| Application Area | Optimal Granule Size (mm) | Recommended Dosage (kg/m³) | Key Benefits |

|---|---|---|---|

| Water Purification | 0.5 - 1.0 | 20 - 50 | Removes impurities, enhances clarity |

| Catalyst Support | 1.0 - 2.0 | 30 - 60 | Increases surface area and catalytic activity |

| Grinding Media | 3.0 - 5.0 | 50 - 100 | Enhances grinding efficiency and material quality |

| Thermal Insulation | 1.5 - 3.0 | 25 - 75 | Excellent thermal resistance, lightweight |

When working with alumina granules, safety should be your top priority. These granules can be harmful if inhaled. Always wear a dust mask or respirator to protect your lungs. Use safety goggles to shield your eyes. It’s crucial to have gloves on to prevent skin irritation.

Ensure your workspace is well-ventilated. If possible, work outdoors or in a fume hood. Spills should be cleaned immediately to avoid slips. Use proper containers for storage to minimize dust release. Remember to label all materials clearly.

If you are storing or transporting alumina granules, avoid moisture exposure. Humidity can turn them clumpy. Also, review safety data sheets for detailed handling instructions. Being aware of potential risks makes a noticeable difference. It’s important to stay informed and cautious. Mistakes can happen, and reflection on safety practices helps avoid repeating them.