Tabular Alumina is a high-purity alumina material that has garnered significant attention in various industrial applications due to its unique properties and versatility. Characterized by its exceptional thermal stability, low porosity, and high mechanical strength, Tabular Alumina serves as an ideal component for refractory formulations, advanced ceramics, and catalyst supports. This efficient use of Tabular Alumina across multiple sectors such as metallurgy, glass manufacturing, and petrochemicals highlights its importance in enhancing product performance and overall operational efficiency.

In industrial settings, the effective utilization of Tabular Alumina can lead to substantial benefits, including improved thermal insulation, increased chemical resistance, and superior mechanical attributes. Understanding how to leverage these properties is crucial for engineers and product developers who aim to optimize material selection and processing techniques. Various parameters, such as particle size, purity levels, and sintering conditions, must be carefully considered to achieve the desired performance outcomes.

Moreover, the growing trend of sustainability in industrial practices further emphasizes the need for innovative use of Tabular Alumina. By substituting less efficient materials with this high-performance option, industries can not only enhance their product quality but also reduce their environmental impact. As the demand for advanced materials continues to rise, the effective application of Tabular Alumina will play a pivotal role in shaping the future of numerous manufacturing processes and industries.

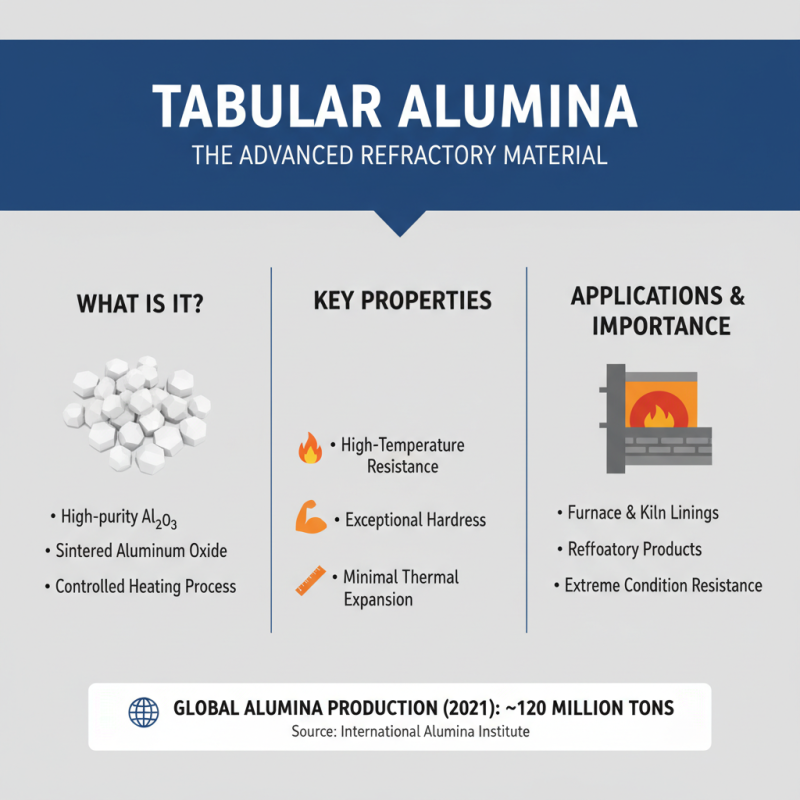

Tabular alumina is a high-purity alumina produced through the controlled sintering of aluminum oxide. Known for its unique properties, tabular alumina exhibits exceptional hardness, high-temperature resistance, and minimal thermal expansion. According to the International Alumina Institute, the global production of alumina reached approximately 120 million tons in 2021, emphasizing the growing importance of alumina derivatives in various industrial applications. Its ability to withstand extreme conditions and its low reactivity with other materials make tabular alumina an ideal choice for refractory applications, including linings for furnaces and kilns.

One of the key benefits of tabular alumina is its outstanding thermal stability, which allows it to maintain structural integrity at temperatures exceeding 1700°C. Additionally, it has a high modulus of rupture, making it suitable for applications where mechanical strength is critical. A report from the Market Research Future indicates that the demand for advanced ceramic materials, including tabular alumina, is expected to grow at a compound annual growth rate (CAGR) of 5.5% through 2026, driven by increasing investments in the metal and mining industries. The inert nature of tabular alumina also minimizes contamination risks, ensuring that its application in sensitive environments meets stringent quality standards.

Tabular alumina is a high-purity form of aluminum oxide that is highly valued in various industrial applications due to its unique properties. Its structure is characterized by large, dense particles, which make it ideal for use in refractory materials. In this capacity, tabular alumina exhibits excellent thermal stability and resistance to extreme temperatures, making it suitable for applications in the metal casting industry, where it is often used as a lining material for ladles and furnaces.

Another significant application of tabular alumina is in the production of advanced ceramics. Its high mechanical strength and low thermal conductivity allow for the creation of durable and efficient ceramic products. These ceramics are employed in various fields, including electronics, automotive, and aerospace industries, where they are used in components that require high wear resistance and toughness. Furthermore, tabular alumina serves as an effective filler material in various composite materials, enhancing their thermal and mechanical properties while also contributing to lighter weight solutions in structural applications.

| Application Area | Properties Required | Advantages of Tabular Alumina | Typical Usage Amount |

|---|---|---|---|

| Refractories | High thermal stability, low thermal conductivity | Excellent resistance to thermal shock | 10-30% in refractory mixes |

| Catalysts | High surface area, porosity | Enhanced activity and selectivity | 5-15% in catalyst formulations |

| Ceramics | Mechanical strength, durability | Improved mechanical properties | 20-40% in ceramic applications |

| Abrasives | Hardness, wear resistance | Longer tool life | 15-25% in abrasive products |

| Foundry Sands | High thermal conductivity, minimal expansion | Improved casting accuracy | 30-50% in foundry applications |

When handling and processing tabular alumina, it is essential to prioritize safety and efficiency. First, ensure that proper personal protective equipment (PPE) is worn, including gloves, goggles, and masks, as tabular alumina dust can be harmful if inhaled or if it comes into contact with skin. Additionally, working in a well-ventilated area can help minimize exposure to airborne particles.

When storing tabular alumina, use sealed containers to prevent contamination and moisture absorption, which can affect the material's performance.

During processing, it's crucial to maintain the integrity of the alumina by using appropriate handling equipment that avoids the introduction of impurities. Employing techniques such as pneumatic conveying can facilitate the movement of tabular alumina without generating excessive dust.

Furthermore, regularly calibrating your equipment ensures consistent particle size and quality, which are vital for optimizing the material's performance in industrial applications. Implementing these best practices not only enhances operational efficiency but also contributes to a safer working environment.

Tabular alumina is increasingly recognized for its role in enhancing the performance of refractory materials, particularly in high-temperature industrial processes. Its unique properties, such as low porosity, high thermal stability, and excellent mechanical strength, make it an ideal candidate for use in the production of refractories. According to a recent market analysis report, the global refractory market is projected to grow from USD 25 billion in 2021 to approximately USD 33 billion by 2026, with tabular alumina playing a pivotal role in driving this growth due to its superior characteristics.

One of the primary applications of tabular alumina in refractory materials is in the manufacturing of furnace linings and kiln furniture. The material's high resistance to thermal shock and corrosion makes it particularly suitable for environments subjected to extreme temperatures and harsh chemical exposures. Studies indicate that refractories incorporating tabular alumina can exhibit a reduction in thermal conductivity by up to 20% compared to those made from traditional alumina sources, thereby enhancing energy efficiency in industrial furnaces. Furthermore, the use of tabular alumina can extend the lifespan of refractory linings, reducing maintenance costs and downtime, which is vital for industries that rely heavily on uninterrupted production cycles.

Moreover, optimizing the grain size and distribution of tabular alumina within refractory formulations can significantly improve overall performance. Research has shown that smaller grain sizes can enhance the densification process during firing, leading to superior mechanical properties and resistance to wear. The implementation of advanced manufacturing techniques, such as additive manufacturing and precision casting, can also facilitate the effective use of tabular alumina in customized refractory applications, thus meeting the specific demands of various industrial sectors. As industries continue to seek improvements in material performance and sustainability, the strategic use of tabular alumina in refractory materials will undoubtedly become more prevalent.

The future of tabular alumina applications is currently being shaped by several trends and innovations, particularly in industries like ceramics, refractories, and advanced materials. The development of ultra-high-temperature ceramics that can withstand extreme environments is driving the demand for tabular alumina due to its unique physical properties, such as low thermal expansion and high thermal conductivity. These characteristics make it an ideal candidate for use in applications that require exceptional durability and efficiency.

One notable trend is the integration of nanotechnology into the formulation of tabular alumina, which enhances its properties and opens up new avenues for application. For example, by using nano-sized particles, manufacturers can create composites that exhibit improved strength, better thermal stability, and increased resistance to wear. This innovation can significantly impact industries like aerospace and automotive, where materials must meet stringent performance criteria.

Tip: When exploring the use of tabular alumina, consider the specific requirements of your application, such as temperature tolerance and mechanical strength. This will help you select the right grades and formulations to optimize performance.

Additionally, environmental sustainability is becoming a core focus, with researchers investigating methods to recycle and repurpose tabular alumina waste. Innovations in production processes aimed at reducing energy consumption during the manufacturing of tabular alumina are also on the rise. Companies that adopt these sustainable practices not only contribute to a healthier planet but may also realize cost savings and improved market competitiveness.

Tip: Keep an eye on emerging research and developments in tabular alumina production. Collaborating with research institutions can provide insights into cutting-edge techniques and sustainability initiatives that can benefit your operations.