In the realm of modern materials, Alumina Granules stand out for their diverse applications. Dr. Emily Chen, a renowned expert in ceramic materials, once said, "Alumina Granules are critical for innovations in multiple industries." This highlights their significance beyond mere industrial use.

Alumina Granules are part of daily life, from electronics to healthcare. Their natural properties make them indispensable. In electronics, they enhance performance and durability. In the biomedical field, they ensure safer options for implants. However, the diversity in their application raises questions about proper usage and environmental impact.

Despite their advantages, we must reflect on potential downsides. Over-reliance on Alumina Granules could lead to sustainability concerns. It's vital to balance innovation with responsibility. Exploring the top uses of Alumina Granules reveals both their benefits and the need for thoughtful engagement in their application.

Alumina granules are prominent in water treatment industries. Their high surface area gives them excellent adsorption properties. They effectively remove impurities from water, which is crucial for safe consumption. A recent industry report showed that using alumina granules can improve water purification efficiency by up to 30%.

In addition to adsorption, these granules also support coagulation processes. This helps in clumping together smaller particles, making them easier to filter out. Studies indicate that alumina granules can significantly reduce heavy metals in wastewater. This feature is vital for environmental safety. However, the effectiveness can vary based on water quality.

Not all alumina granules perform the same way. Factors like particle size and specific surface area can influence results. Some applications may require further optimization. It's essential to conduct regular assessments. Testing different granule types can lead to better outcomes. There’s always room for improvement in treatment methods.

Alumina granules play a significant role in pharmaceuticals and cosmetics. They are versatile and highly useful in multiple applications. In pharmaceuticals, they serve as excipients, assisting in the formulation of tablets. Their properties enhance the stability and bioavailability of active ingredients.

In cosmetics, alumina granules are valued for their absorbent qualities. They help control oil and moisture levels in various products. This natural mineral adds a smooth texture to creams and powders, improving user experience. However, some consumers may have concerns about the sourcing and purity of these granules. It's crucial for manufacturers to prioritize high-quality materials.

Despite their benefits, the use of alumina in cosmetics is sometimes questioned. Some studies suggest potential skin irritation or allergic reactions. Consumers must be mindful and choose products carefully. Transparency in sourcing and production processes is essential for trust. Balancing effectiveness with safety is a challenge that requires ongoing reflection.

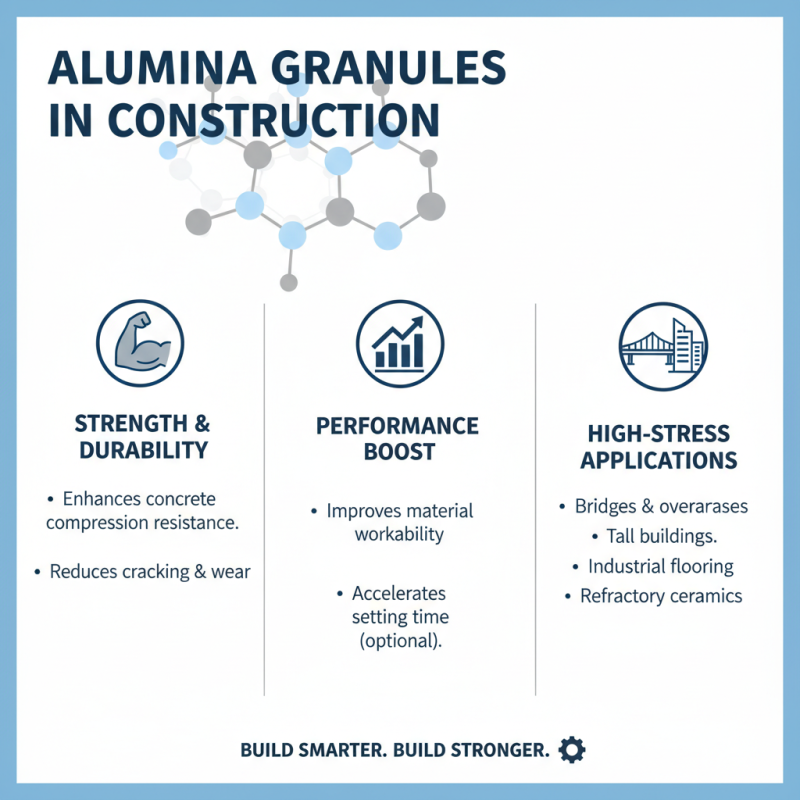

Alumina granules play a vital role in construction materials. They are often used in concrete production to enhance strength and durability. This fine material can improve the overall performance of various building projects. It is particularly useful in high-stress environments, such as bridges and high-rise buildings.

The incorporation of alumina granules can also aid in reducing the weight of construction materials. Lighter materials can lead to easier handling and installation. However, the mixing process must be precise. Too much alumina can weaken the material instead of enhancing it. This is a common oversight that many construction teams face.

Moreover, alumina granules improve insulation properties. Structures built with this material can better regulate temperature. This leads to energy savings in heating and cooling. Yet, the availability and cost of alumina can vary. This sometimes makes it a challenging option for smaller projects. Careful consideration should always be taken when choosing materials for construction.

Alumina granules play a crucial role in ceramic production. These granules help enhance the mechanical strength of ceramic products. The addition of alumina significantly improves the durability of ceramics. Many industries rely on this material for high-performance applications.

In ceramics, alumina provides thermal stability. It helps maintain structural integrity under high temperatures. This makes it ideal for products used in harsh environments. From pottery to advanced engineering ceramics, alumina is valued for its versatility. However, it's vital to ensure the correct size and distribution of these granules. Poorly mixed granules can lead to inconsistencies in finished products.

Tip: Always test your alumina granules before large-scale production. This ensures you achieve the desired properties in your ceramic materials. Also, consider the source of your alumina. It affects the quality and performance of the final product.

Remember, the production process can always be improved. Experimenting with different proportions can lead to better outcomes. Take time to refine your techniques and materials. This can help you avoid common pitfalls and enhance your product quality.

Alumina granules have gained prominence in industrial applications, particularly in abrasives. These versatile particles excel in applications ranging from surface finishing to grinding. Their unique properties allow for effective use in various abrasive formulations. By providing excellent hardness and chemical stability, alumina granules can achieve exceptional performance in tough industrial environments.

In abrasive tools, alumina granules play a critical role. They can be mixed with bonding agents to create durable products like cutting wheels and sandpapers. The granules come in various sizes, enabling precise control over the surface finish. Despite their advantages, the effectiveness of these granules depends on careful selection. Not every application can benefit from the most aggressive grit; sometimes, finer granules are necessary for a smoother finish.

Moreover, using alumina granules requires consideration of safety protocols. While they are effective, dust generated during processing can pose health risks. Proper ventilation and protective equipment are essential. The reality is, the volatility of various ingredients in synthetic abrasives must be managed. It's essential to balance performance with safety measures, making the selection process more complex than it appears at first glance. Effective use often involves trial and error.