When selecting the most suitable Alumina White for industrial applications, it is imperative to understand the unique characteristics and properties that different formulations may offer. According to Dr. Emily Carter, a renowned expert in the field of materials science, "The choice of Alumina White can significantly impact the performance and durability of industrial products." This highlights the critical need for manufacturers to thoroughly evaluate their requirements before making a decision.

Alumina White, known for its exceptional strength and thermal stability, is utilized across a range of industries, from ceramics to refractories. The variation in particle size, purity levels, and processing techniques can lead to diverse performance outcomes. Hence, understanding these factors and their implications is essential for achieving optimal results in any industrial setting. By exploring the various types of Alumina White and considering the specific demands of their applications, professionals can make informed choices that enhance overall efficiency and product reliability.

When selecting the best alumina white for industrial applications, several key factors must be considered to ensure optimal performance and cost-effectiveness. The purity level of alumina white is crucial;

higher purity materials, often above 99% offer superior properties such as enhanced thermal stability and chemical resistance. According to a market analysis report from Grand View Research,

the demand for high-purity alumina is projected to grow significantly, driven by applications in ceramics and electronics.

The particle size distribution of alumina white also plays a vital role in its application.

Fine particles provide better flowability and surface finish, which are essential for coatings and advanced ceramic products. Conversely,

coarser grades are preferred in applications requiring higher bulk density and durability.

A report from Market Research Future highlights that the global alumina market is expected to witness a CAGR of

5.7% through 2025, emphasizing the growing trend towards tailored particle sizes for specific industrial needs.

Tips: When sourcing alumina white, consider conducting a thorough analysis of the particle size distribution to match the specific requirements of your application. Additionally, keep abreast of market trends and developments,

as new grades and formulations are regularly introduced to address evolving industry demands. Always consult with material scientists or industry experts to make informed decisions based on empirical data.

When selecting the best alumina white for industrial applications, understanding the comparative analysis of different grades is crucial for optimizing performance and cost efficiency. Alumina white is available in various grades, each possessing distinct physical and chemical properties that make them suitable for specific applications.

For example, higher purity alumina grades demonstrate superior hardness and wear resistance, making them ideal for use in harsh environments such as ceramics and abrasives. In contrast, lower grades might be sufficient for applications where cost is a more significant concern than performance.

Tips: When evaluating alumina grades, consider the specific demands of your application, including temperature stability, chemical resistance, and mechanical strength. Conducting thorough testing to compare the performance of different grades in real-world scenarios can also provide valuable insights.

Additionally, it’s essential to take into account the particle size and distribution of alumina white, as these factors influence its reactivity and suitability for various processes. A finer particle size often leads to increased surface area, enhancing the material's effectiveness in applications like coatings or catalysis. However, the choice should align with the intended use, as finer particles may also result in higher production costs. Always ensure that the selected alumina grade meets the regulatory requirements and industry standards pertinent to your application.

The properties of alumina white play a crucial role in enhancing industrial process efficiency across various applications. This material is characterized by its high purity, excellent thermal stability, and resistance to corrosion. These attributes make it an ideal choice for industries seeking materials that can withstand harsh operational conditions. For instance, in ceramic manufacturing, the purity of alumina white ensures uniformity and consistency in the final products, which is vital for maintaining quality control and optimizing production rates.

Moreover, the particle size and morphology of alumina white significantly influence its performance in industrial processes. Finer particles can enhance flowability, leading to smoother processing and reduced energy consumption during mixing and formulation. Additionally, the specific surface area and reactivity of alumina white can affect the efficiency of catalytic processes in chemical manufacturing. By selecting the right type of alumina white with the desired properties, companies can not only improve their process efficiencies but also minimize waste and operational costs, ultimately leading to more sustainable production practices.

When considering high-purity alumina white for industrial applications, a detailed cost-benefit analysis is essential. High-purity alumina (aluminum oxide) is known for its exceptional chemical stability, thermal resistance, and electrical insulation properties. Reports indicate that industries utilizing high-purity alumina experience reduced operational costs in the long term due to lower maintenance and replacement rates. For instance, the materials market is projected to grow, with the demand for high-purity alumina expected to rise by 9.2% annually through 2025, driven by its applications in ceramics and electronics.

Investing in high-purity alumina white may have higher upfront costs, but the benefits can outweigh the initial investment. The low thermal conductivity and high melting point contribute to enhanced durability in extreme conditions, making it a suitable choice for various applications from refractory materials to advanced coatings. A recent industry study noted that companies using high-purity alumina reported an average reduction of 15% in manufacturing costs over five years, emphasizing its value as a long-term investment.

Tips: When selecting high-purity alumina, evaluate performance characteristics specific to your application's requirements, such as purity level and particle size. It's also advisable to assess supplier reliability and product certifications, as these factors can significantly impact both quality and overall cost efficiency. Regularly revisiting supplier agreements can uncover opportunities for bulk purchasing discounts or improved pricing structures that enhance your cost-benefit ratio.

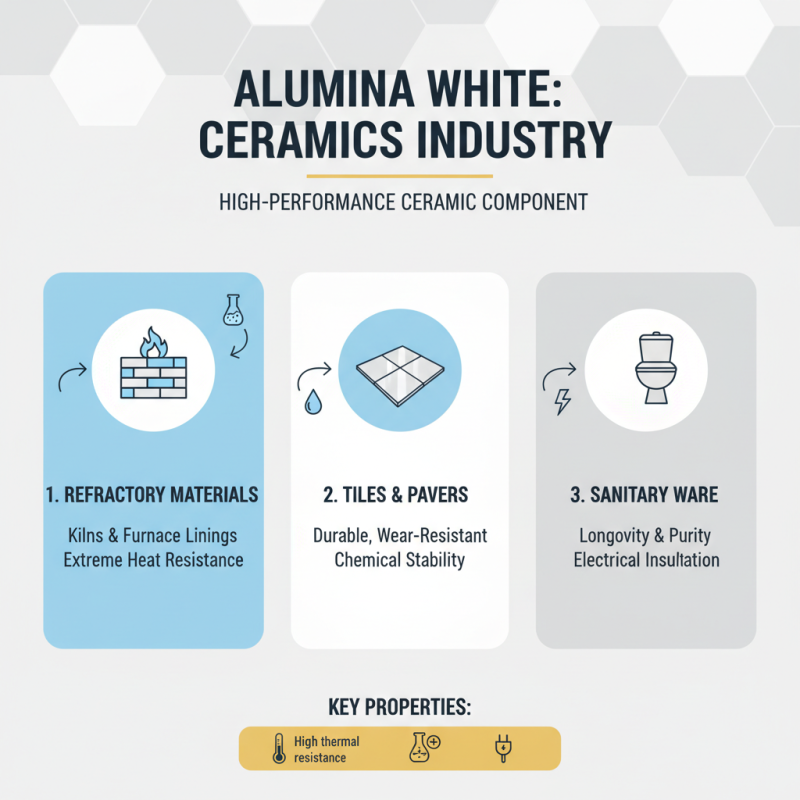

Alumina white, a high-purity alumina derivative, has found diverse applications across various industries due to its excellent properties such as high thermal resistance, chemical stability, and electrical insulation. In the ceramics industry, alumina white serves as a critical component in manufacturing high-performance refractory materials, tiles, and sanitary ware. Its ability to withstand extreme temperatures makes it ideal for applications in kilns and furnaces, ensuring durability and longevity of the products.

In the field of electronics, alumina white is increasingly utilized in the production of substrates for circuit boards and components. Its insulating properties contribute to the efficiency and efficacy of electronic devices, while its thermal conductivity assists in managing heat generation. Moreover, the automotive industry employs alumina white in brake pads and composites, benefiting from its wear resistance and contributing to overall vehicle safety.

**Tips:** When selecting alumina white for industrial applications, consider factors such as particle size and purity, as these can influence the performance of the final product. Conduct thorough testing to assess compatibility with other materials in your application. Additionally, ensure that the sourcing of alumina white complies with industry standards to maintain quality and safety in your operations.