Tabular Alumina stands out as a versatile material in the industrial sector. Its unique properties make it suitable for various applications, including ceramics, refractories, and abrasives. According to a recent report by Market Research Future, the global Tabular Alumina market is expected to grow at a CAGR of 5.1% through 2025. This growth highlights its increasing significance in industrial processes.

Dr. Emily Roberts, an expert in material science, notes, “Tabular Alumina offers unmatched durability and thermal stability.” Such characteristics are essential for industries focusing on high-performance solutions. For example, in the refractory industry, Tabular Alumina withstands extreme temperatures, ensuring longer lifespans and improved efficiency.

However, industries must consider the sourcing and processing of Tabular Alumina. While it offers many advantages, not all suppliers meet quality standards. It is crucial for manufacturers to evaluate their options diligently. Rushing these decisions can lead to subpar products and unexpected costs. Therefore, the effective use of Tabular Alumina requires careful deliberation and a commitment to quality.

Tabular alumina is a dense, high-purity alumina material with unique properties. It boasts an exceptionally high melting point, usually around 2050°C. This stability makes it ideal for various high-temperature applications. The average porosity of tabular alumina is very low, usually below 1%. This feature enhances its mechanical strength and durability.

In the steel industry, tabular alumina is crucial. According to a 2022 industry report, its use in refractories allows for better thermal conductivity and lower thermal expansion. These properties contribute to longer service life and reduced maintenance costs in furnaces. Moreover, in the ceramics sector, users appreciate its alkali resistance. It prevents chemical degradation in challenging environments, promoting product lifespan.

However, some challenges exist. Sourcing tabular alumina can be inconsistent, affecting availability. Quality variations may also lead to unpredictable results in end products. Industries need to ensure they understand their suppliers thoroughly to mitigate these risks. Reliable data on sourcing and processing methods can be beneficial to navigate this complexity effectively.

Tabular Alumina is an exceptional material with various industrial applications. Its high purity and superior hardness make it popular in refractories. Data from industry reports show that the global market for refractory materials is projected to reach $50 billion by 2026. Tabular Alumina, with its low thermal expansion and excellent corrosion resistance, plays a vital role in this sector.

In the ceramic industry, Tabular Alumina is used to enhance mechanical strength and thermal stability. According to a recent study, the demand for advanced ceramics is expected to grow by 6% annually through 2025. This growth highlights the importance of using high-quality materials like Tabular Alumina in producing components for demanding environments.

However, sourcing Tabular Alumina can be challenging. Some suppliers may not meet rigorous quality standards. This inconsistency in material properties can lead to performance issues in end products. Ensuring that manufacturers adhere to quality regulations is crucial. Critical evaluation of suppliers becomes a necessity for achieving optimal results.

Tabular alumina is gaining attention for its advantages in manufacturing processes. This material is known for its high purity and excellent thermal properties. It can improve the performance of refractory materials. Its uniform, fine structure enhances mechanical strength and stability under high temperatures.

In addition to physical properties, tabular alumina offers benefits in various industrial applications. For instance, in the production of ceramics, it provides better wear resistance. Some manufacturers have found it effective in reducing defects in their products. Yet, the cost of tabular alumina may deter some, leading to a need for careful budgeting.

While its advantages are clear, there are challenges to consider. Not all manufacturers can access high-quality sources consistently. The processing of tabular alumina can also be complex. This complexity may require additional training for staff. Therefore, embracing tabular alumina demands both commitment and reflection on production practices.

Tabular alumina stands out among various alumina forms for its unique properties. Its high thermal stability makes it ideal for industries like ceramics and electronics. Tabular alumina boasts a dense microstructure, which enhances its durability in harsh environments. This characteristic is crucial for applications requiring high-temperature stability.

When compared to other alumina types, tabular alumina shows superior mechanical strength. It performs better than traditional alpha and gamma alumina in many scenarios. This strength leads to enhanced performance in refractory applications. However, tabular alumina can be more expensive than its counterparts. Industries often weigh the cost against the long-term benefits it offers.

Some users may find tabular alumina difficult to source. This limitation can affect production timelines. Additionally, the specific particle size required for certain applications can add complexity. Balancing these factors is essential for optimizing its use in various industrial settings. Evaluating whether it meets an organization’s needs is not always straightforward.

| Property/Dimension | Tabular Alumina | Alpha Alumina | Hygroscopic Alumina | Activated Alumina |

|---|---|---|---|---|

| Density (g/cm³) | 3.65 | 3.97 | 3.45 | 3.50 |

| Porosity (%) | 0.1 | 0.5 | 20.0 | 30.0 |

| Melting Point (°C) | 2050 | 2050 | 2000 | 2000 |

| Thermal Conductivity (W/mK) | 30 | 24 | 12 | 14 |

| Applications | Refractories, Catalyst Supports | Ceramics, Electrical Insulation | Adsorbents, Desiccants | Catalysts, Water Purification |

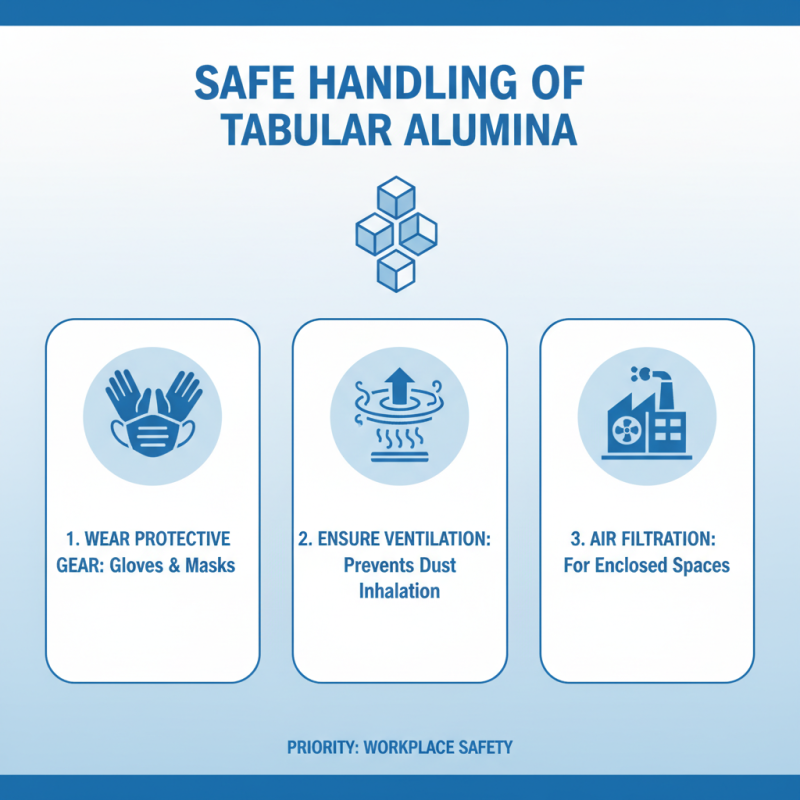

Tabular alumina is widely used in various industrial applications due to its unique properties. When handling tabular alumina, safety should be a priority. Protective gear such as gloves and masks is essential. The lightweight nature of tabular alumina can create dust, making proper ventilation important. Work in an enclosed space may require air filtration systems.

Utilization involves careful planning. Measure quantities accurately before use. This minimizes waste and enhances efficiency. Considerations for storage are crucial. Keep tabular alumina in sealed containers. Moisture can degrade its quality. Regularly inspect storage conditions to prevent contamination.

Despite its advantages, challenges can arise. Not all applications require tabular alumina's high performance. Assess your specific needs to avoid unnecessary costs. Experimentation may lead to unexpected results. Take time to reflect on process adjustments. Learning from trial and error can improve outcomes in future projects.