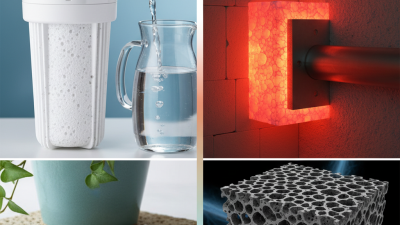

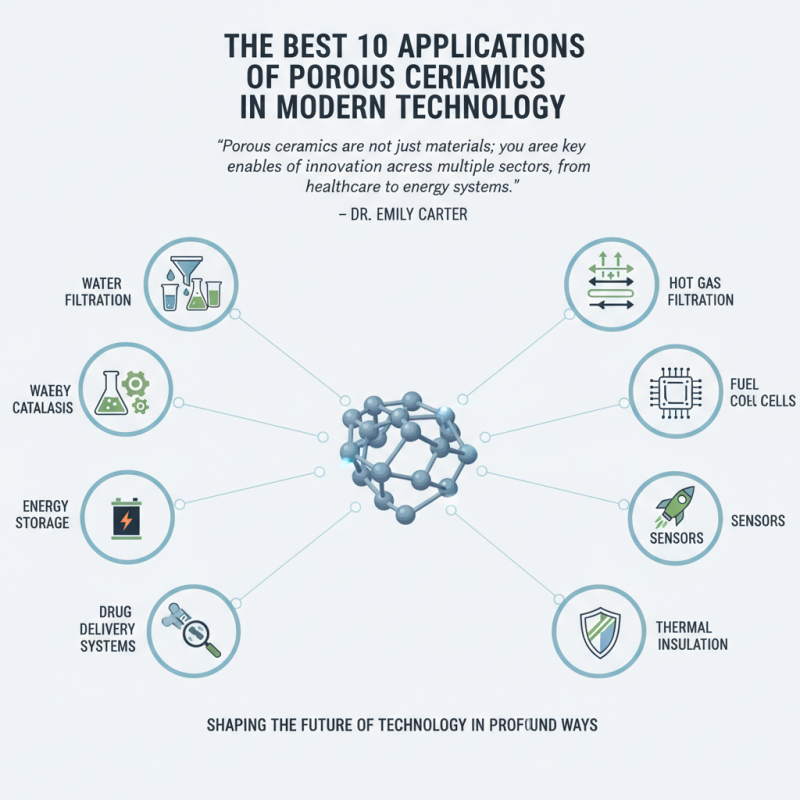

In the ever-evolving landscape of modern technology, the versatility and utility of porous ceramics have drawn increasing attention from researchers and industry experts alike. Dr. Emily Carter, a leading figure in the field of advanced materials, emphasizes their significance with the statement, “Porous ceramics are not just materials; they are key enablers of innovation across multiple sectors, from healthcare to energy systems.” This highlights the critical role that porous ceramics play in driving advancements in various applications.

Porous ceramics, with their unique structural and functional properties, offer solutions that address today’s technological challenges. From water filtration systems that ensure clean drinking water to their role in catalysis and energy storage, these materials exhibit remarkable adaptability and efficiency. Furthermore, the integration of porous ceramics in biomedical applications, such as bone grafting and drug delivery systems, underscores their importance in improving human health outcomes. As we delve into the best applications of porous ceramics, it becomes evident that they represent a fascinating intersection of material science and practical utility, shaping the future of technology in profound ways.

Porous ceramics are gaining prominence in advanced filtration systems due to their unique properties, such as high permeability and structural integrity. Their intricate pore structure allows for efficient filtration of particulates, making them ideal for applications in water purification and air filtration. According to a report by Grand View Research, the global ceramic filtration market is projected to reach $2.8 billion by 2025, driven by the increasing demand for clean drinking water and stringent environmental regulations. This growth indicates a robust shift towards utilizing porous ceramic materials in filtration technologies.

One notable application of porous ceramics is in membrane filtration systems, where they serve as effective barriers against bacteria and contaminants. The National Science Foundation emphasizes that membranes made from porous ceramics can achieve filtration efficiencies greater than 99%, significantly surpassing traditional materials. Additionally, their chemical stability allows them to be used in extreme conditions, extending their lifespan and reducing maintenance costs.

Tips: When selecting a porous ceramic for filtration applications, consider factors such as pore size, material composition, and resistance to chemical degradation. Engage with professionals who can conduct thorough assessments of your specific needs to ensure optimal performance. Furthermore, regularly monitor the performance of your filtration system to identify potential issues before they become significant.

Porous ceramics have emerged as a pivotal material in the field of biomedical implants and devices. Their unique properties, such as biocompatibility, mechanical strength, and customized porosity, make them ideal for applications in bone regeneration and surgical implants. According to a report published by Research and Markets, the global market for ceramic biomaterials is projected to reach USD 2.41 billion by 2026, growing at a CAGR of 6.5%. This growth is driven by the increasing demand for advanced bone grafts and dental implants, highlighting the significant role porous ceramics play in modern biomedicine.

The porosity of these ceramics enables high levels of bioactivity, facilitating bone cell attachment and growth. Studies indicate that scaffold structures made from porous ceramics can promote osteogenesis, leading to enhanced healing in orthopedic applications. For instance, a study reported in the Journal of Biomedical Materials Research indicates that implants with a porosity range of 20-50% showed superior results in bone integration compared to non-porous alternatives. Moreover, the tunable mechanical properties of porous ceramics allow for the design of implants that closely mimic the natural stiffness of bone, reducing the risk of stress shielding and improving patient outcomes post-surgery.

Porous ceramics have emerged as a critical component in catalysis and chemical reactions, thanks to their unique structural properties that provide high surface area and excellent thermal stability. According to a report by MarketsandMarkets, the global catalytic materials market is projected to reach USD 34.2 billion by 2026, with porous ceramics playing a significant role due to their versatility in various applications. The ability of these materials to facilitate reactions while maintaining structural integrity under extreme conditions makes them a go-to choice in industries ranging from petrochemicals to pharmaceuticals.

In catalytic processes, the porosity of these ceramics allows for the adsorption of molecules, thus enhancing reaction efficiency. The intricate network of pores provides numerous active sites for chemical interactions, which can significantly accelerate reaction rates. A study published in the Journal of Catalysis indicated that the use of porous ceramic supports improved the turnover frequency of catalysts by over 30% compared to traditional materials. This enhancement is particularly valuable in heterogeneous catalysis, where the solid catalyst promotes the conversion of reactants in liquid or gas phases. Moreover, porous ceramics can be engineered to tailor their pore size and structure, optimizing them for specific catalytic functions and enabling more efficient resource utilization in chemical processes.

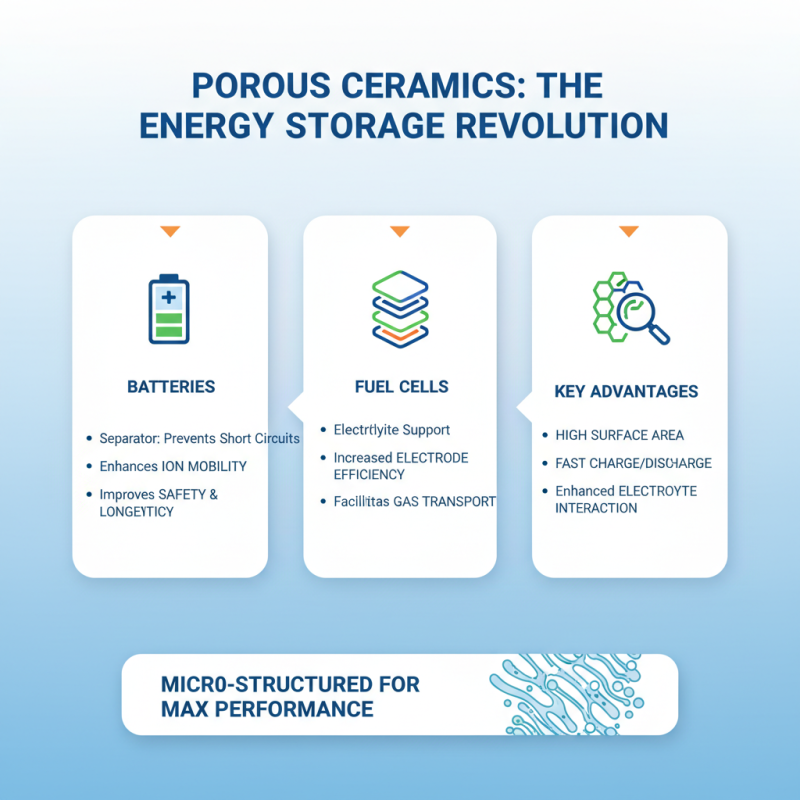

Porous ceramics have emerged as a significant component in the field of energy storage, particularly within batteries and fuel cells. Their unique structure, characterized by finely distributed pores, enhances the performance and efficiency of these energy systems. In batteries, porous ceramics act as separators that allow ionic mobility while preventing short circuits, thus improving the overall safety and longevity of the battery. Additionally, the high surface area of porous ceramics facilitates better electrolyte interaction, leading to increased charge and discharge rates.

In fuel cells, porous ceramics serve multiple roles—primarily as electrodes and electrolyte supports. Their ability to withstand high temperatures and corrosive environments makes them ideal for enhancing the electrochemical reactions necessary for fuel cell operation. The porous nature provides optimal pathways for gas diffusion, which is crucial for maintaining performance efficiency. Furthermore, these materials can be engineered to optimize their porosity and connectivity, tailoring them for specific energy demands and advancing the development of sustainable energy technologies.

Porous ceramics have emerged as pivotal materials in the field of environmental remediation, offering innovative solutions to tackle various pollution challenges. Their intrinsic porous structure allows for high surface area and porosity, which facilitate the adsorption of contaminants from water and air. For instance, these materials can effectively capture heavy metals, organic pollutants, and even particles, making them invaluable in wastewater treatment processes. The ability of porous ceramics to function in diverse environmental conditions enhances their applicability, providing a robust choice for sustainable pollution management.

Recent advancements in the development of functionalized porous ceramics have further amplified their effectiveness in environmental remediation. Innovations such as modifications with nanomaterials and bioactive agents enable these ceramics to not only absorb pollutants but also promote degradation and mineralization, transforming harmful substances into less toxic forms. This dual approach is particularly advantageous in addressing organic pollutants that resist conventional treatment methods. The ongoing research and development in this field continue to explore novel synthesis techniques and applications, paving the way for enhanced remediation technologies that can significantly mitigate environmental pollution and contribute to a healthier ecosystem.