Zirconia Tubes are becoming essential in various industrial applications. They offer unique benefits due to their exceptional properties. These tubes are highly resistant to heat and chemicals, making them suitable for extreme environments.

Moreover, Zirconia Tubes exhibit excellent mechanical strength. They can withstand high stresses without breaking. This reliability is crucial in industries like aerospace and electronics. Despite their advantages, some challenges exist. For instance, cost can be a factor for small manufacturers.

Yet, the long-term benefits in efficiency and durability often outweigh initial expenses. Industries must consider these aspects when choosing materials. The advantages of Zirconia Tubes could lead to innovative solutions for complex problems.

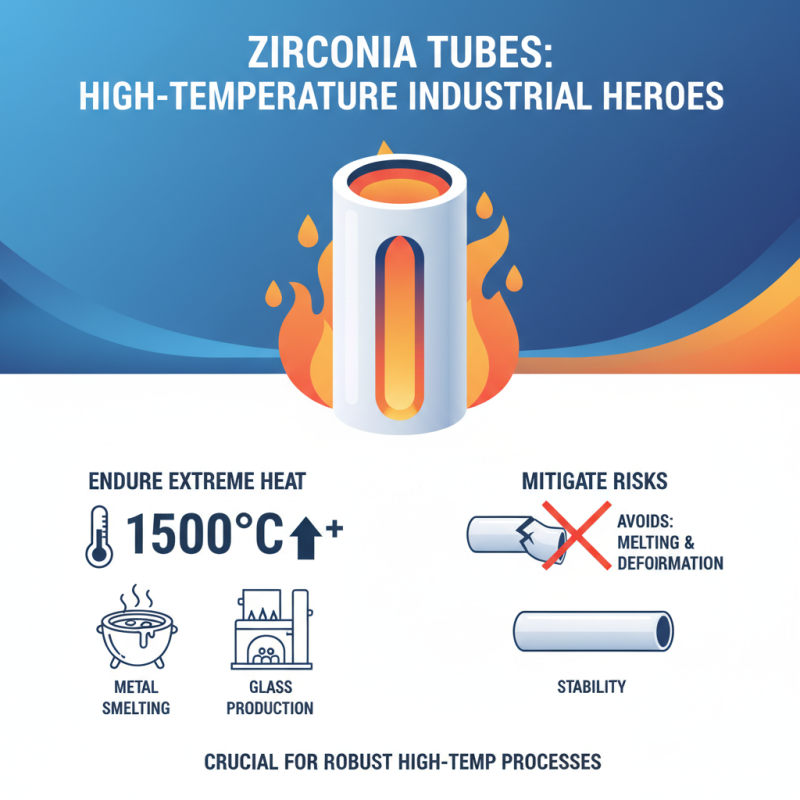

Zirconia tubes are increasingly popular in high-temperature industrial environments. They can endure extreme heat, reaching temperatures over 1,500 °C. This is crucial for processes like metal smelting and glass production. Localized melting and deformation can become major issues for materials used at these temperatures. Zirconia’s stability helps mitigate these risks.

These tubes display outstanding chemical resistance. They resist corrosion from strong acids and alkalis. This resistance is vital in industries dealing with reactive materials. Research indicates that zirconia can outlast conventional materials by 50% in some applications. Workers have reported fewer failures and less downtime since using zirconia tubes.

However, challenges remain. The brittle nature of zirconia makes it prone to crack under stress. This can lead to unexpected maintenance costs. Proper handling and installation are essential for maximizing their lifespan. Ongoing monitoring will help identify potential weaknesses early. Balancing performance with these challenges requires careful planning. Organizations must evaluate their specific needs thoroughly before implementation.

Zirconia tubes are gaining popularity in various industrial sectors. Their impressive wear resistance sets them apart from traditional materials. In many applications, they withstand harsh conditions better than metals or plastics. For instance, zirconia can endure high temperatures and corrosive environments effectively.

Unlike conventional materials, zirconia is less prone to cracks and scratches. This durability is critical in settings where machinery experiences constant friction. Operators have reported longer service life with zirconia tubes installed. However, not all applications may benefit equally from this material. Some processes might require different properties, like flexibility or lower cost.

Despite its advantages, the production of zirconia tubes can be resource-intensive. This raises some concerns about environmental impact. It's essential to weigh these factors against the performance benefits. Industrial users should thoroughly evaluate their needs before opting for zirconia tubes. Balancing durability and sustainability is vital for future advancements.

Zirconia tubes have gained popularity in various industrial applications due to their enhanced properties. The chart below illustrates a comparison of wear resistance between zirconia tubes and traditional materials.

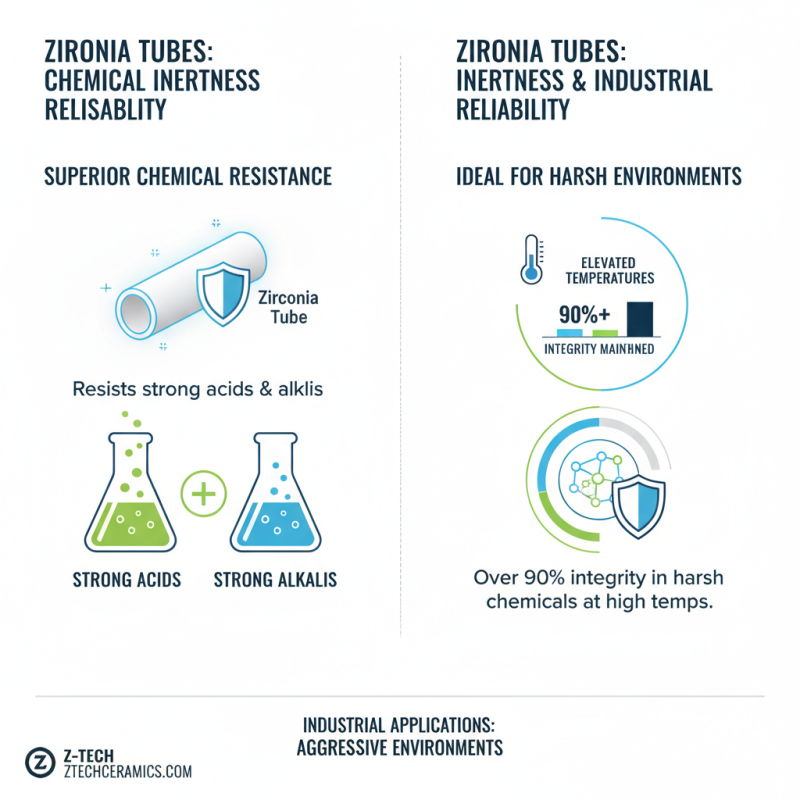

Zirconia tubes are gaining popularity in industrial applications due to their remarkable chemical inertness. This property makes them ideal for use in aggressive environments. Zirconia can withstand strong acids and alkalis, providing a protective barrier against corrosive substances. Research indicates that zirconia maintains over 90% of its integrity when exposed to harsh chemicals at elevated temperatures.

When selecting materials for specific applications, consider chemical reactions. Zirconia does not leach chemicals into surrounding environments, which is essential for sensitive processes. Industries like pharmaceuticals and biotech benefit immensely. The inert nature of zirconia minimizes contamination risks, ensuring product integrity.

Tip: Always analyze the compatibility of materials with specific chemicals. Test under actual operating conditions before full-scale implementation.

Additionally, the durability of zirconia tubes under mechanical stress elevates their utility. They can handle significant pressure without failure. This durability can reduce replacement costs and downtime. While zirconia systems are often more expensive initially, the long-term savings from reliability should not be overlooked.

Tip: Assess long-term operational costs versus upfront expenditures when choosing materials. This can lead to more informed decisions.

Zirconia tubes are gaining attention in various industrial applications. One key feature is their thermal conductivity. These tubes are known for their impressive energy efficiency. They help maintain stable temperatures in various processes, such as manufacturing. This stability is crucial in reducing energy consumption.

When using zirconia tubes, consider insulation materials. Proper insulation can boost energy efficiency even further. Monitor temperature regularly. Fluctuations can mean energy waste. Small changes in temperature can lead to higher costs.

Another aspect to explore is the durability of zirconia tubes. They can withstand high temperatures without significant degradation. This longevity means fewer replacements. Fewer replacements lead to cost savings and less environmental waste. However, the initial investment might be higher, so weigh your options carefully.

Incorporate zirconia tubes into heat-exchange systems too. Their properties enhance thermal regulation. Regular maintenance is still necessary to optimize performance. A lack of care can diminish their effectiveness over time. These considerations will help maximize the advantages of zirconia tubes for energy efficiency.

| Benefit | Description | Thermal Conductivity (W/m·K) | Energy Efficiency Impact |

|---|---|---|---|

| High Strength | Zirconia tubes offer exceptional mechanical strength. | 2.5 | Reduces material failure |

| Corrosion Resistance | Highly resistant to chemical attack. | 2.5 | Longer service life |

| Thermal Shock Resistance | Able to withstand rapid temperature changes. | 2.5 | Minimizes downtime |

| Low Thermal Conductivity | Excellent insulator, promoting energy efficiency. | 2.5 | Reduces energy costs |

| Versatile Applications | Suitable for various industrial applications. | 2.5 | Enhances operational efficiency |

| Lightweight | Reduces the overall weight of applications. | 2.5 | Eases handling and transport |

| Cost-Effectiveness | Long lifespan reduces the need for replacements. | 2.5 | Lower maintenance costs |

| Aesthetic Appeal | Can be used in applications requiring visual appeal. | 2.5 | Enhances product design |

| Recyclability | Can be recycled and reused in production. | 2.5 | Promotes sustainability |

| Environmentally Friendly | Composed of eco-friendly materials. | 2.5 | Supports green manufacturing |

Zirconia tubes offer significant cost-effectiveness for long-term industrial use. These materials are durable and resist wear, which minimizes replacement costs. Industries can benefit from lower maintenance demands over time. The initial investment may seem high, but their lifespan can justify the expense.

In many cases, companies find themselves constantly replacing less durable materials. This leads to unplanned costs that accumulate over years. With zirconia, businesses reduce the frequency of replacements, translating to real savings. However, careful analysis is necessary. Not every industry may experience the same cost benefits.

Moreover, the choice of materials should align with specific applications. Engineering teams must evaluate whether zirconia truly meets their needs. There are instances where other materials might suffice. Exploring these options ensures that decisions are data-driven. Ultimately, selecting materials wisely will influence the bottom line, making the evaluation process crucial.