Tabular Alumina is a versatile and high-performance material that plays a crucial role in various industrial applications. Known for its unique properties, including exceptional wear resistance, high thermal stability, and excellent chemical inertness, Tabular Alumina has become an indispensable component in industries ranging from refractories to ceramics and beyond. Its unique crystalline structure enhances performance in demanding environments, making it an ideal choice for applications that require durability and reliability.

The benefits of utilizing Tabular Alumina extend to improved efficiency and effectiveness in production processes. For instance, its low porosity and high melting point contribute to the longevity of equipment and products, reducing maintenance costs and downtime. Furthermore, the enhanced thermal shock resistance of Tabular Alumina ensures that it can withstand rapid temperature changes, which is essential in applications such as kilns and furnaces. As industries continue to seek advanced materials that can offer superior performance, Tabular Alumina stands out as a top contender that meets these evolving demands.

In conclusion, the myriad advantages of Tabular Alumina highlight its significance in modern industrial practices. With a focus on innovation and performance, industries reliant on high-quality materials will increasingly turn to Tabular Alumina to achieve their operational goals and maintain a competitive edge.

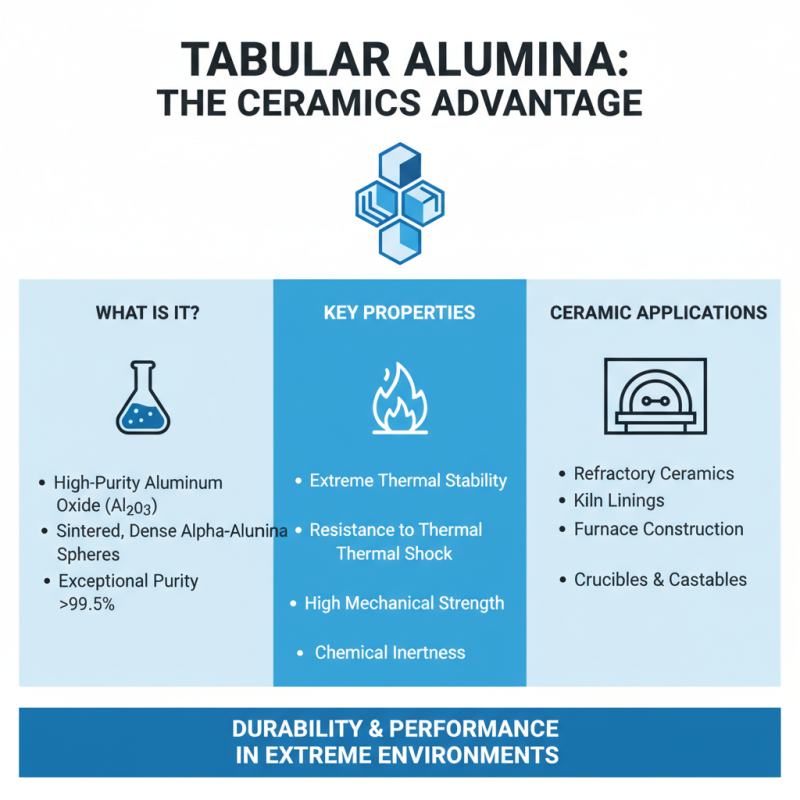

Tabular alumina is a high-purity, synthetic aluminum oxide material characterized by its unique crystalline structure, typically produced by calcining alumina at elevated temperatures. This process converts alpha-alumina into a crystalline, tabular form, resulting in a product that exhibits outstanding properties such as high thermal stability, excellent wear resistance, and low porosity. Its composition primarily consists of alumina (Al2O3), while the absence of impurities enhances its performance in various industrial applications.

The distinctive tabular shape of this alumina allows for optimal packing density, which significantly improves its mechanical strength and thermal conductivity. As a result, tabular alumina is highly regarded in sectors such as refractory materials, ceramics, and castables, where durability and thermal resistance are critical. Its ability to withstand harsh environments makes it a preferred choice for manufacturers aiming for enhanced product longevity and reliability, especially in high-temperature applications.

Tabular alumina is a high-performance material widely used in various industrial applications due to its unique properties. One of its key characteristics is its high purity level, which enhances the quality and durability of the end products. With a low porosity rate, tabular alumina exhibits excellent mechanical strength, making it suitable for demanding environments such as refractories and ceramics. Its thermal stability allows it to withstand extreme temperatures, making it ideal for applications in furnaces and kilns.

Tips: When selecting tabular alumina for your project, consider the specific temperature and mechanical stress conditions your application will face. Ensuring compatibility with other materials can enhance overall performance and longevity.

Another significant property of tabular alumina is its excellent chemical resistance. It does not react adversely with most acids and alkalis, making it a reliable choice in chemical processing industries. Additionally, its low thermal conductivity ensures that heat is retained in critical processes while minimizing energy loss during operation.

Tips: Always evaluate the specific chemical interactions that may occur in your application to maximize the effectiveness of tabular alumina and prevent material degradation over time.

Tabular alumina, a high-purity form of aluminum oxide, is widely utilized across various industries due to its unique properties. In the ceramics sector, it serves as an essential raw material for producing refractory ceramics that can withstand extreme temperatures and harsh environments. Its exceptional thermal stability and resistance to thermal shock make it ideal for applications such as kiln linings and furnace construction, where durability is paramount.

In the metallurgical industry, tabular alumina is used as a filler in aluminum production and as an additive in steel manufacturing. Its ability to enhance the performance of the metallurgical processes is vital, as it contributes to the quality and strength of the final products. Additionally, in the advanced engineering domain, tabular alumina is employed in the production of abrasives and grinding wheels, providing superior hardness and longevity, which helps to improve machining efficiency and reduce downtime. These applications underscore the versatility and importance of tabular alumina in enhancing industrial performance across a spectrum of sectors.

Tabular alumina stands out as a preferred material in various industrial applications due to its unique properties that surpass those of conventional materials. One of the primary advantages of tabular alumina is its exceptional thermal stability, which allows it to withstand high temperatures without degrading. This makes it ideal for industries such as metallurgy and ceramics, where materials must endure extreme conditions. Additionally, tabular alumina exhibits low porosity and excellent mechanical strength, enhancing its durability in demanding environments.

Another significant benefit is its chemical inertness, which means tabular alumina does not react with most chemicals, making it a safe choice for processes involving reactive substances. This contrasts with other materials that may corrode or alter under similar conditions. Furthermore, the use of tabular alumina can lead to improved performance and efficiency in applications like refractories and abrasives, where consistent quality and longevity are critical. These properties not only enhance operational reliability but also contribute to cost savings over time, making tabular alumina a superior option compared to traditional alternatives.

This chart illustrates the advantages of Tabular Alumina over other materials in various industrial applications, highlighting aspects such as thermal conductivity, durability, and chemical resistance.

As industries evolve, the demand for advanced materials like tabular alumina continues to grow. A recent market analysis predicts that the global tabular alumina market will reach approximately $500 million by 2027, fueled by its superior properties in demanding applications such as refractories and ceramics. Key innovations driving this trend include enhanced processing techniques that improve the material's performance. For instance, advancements in manufacturing processes have resulted in increased particle uniformity and optimal porosity, leading to enhanced thermal stability and mechanical strength in high-temperature environments.

Furthermore, the future of tabular alumina is being shaped by increasing applications in non-traditional sectors. Emerging trends emphasize its role in the production of advanced ceramics and as a filler in composites, particularly in aerospace and automotive industries. According to a report from MarketsandMarkets, the use of tabular alumina in ceramic matrices is expected to see a significant uptick, projected to grow at a CAGR of over 8% from 2023 to 2030. This growth reflects a broader industry shift toward materials that not only meet rigorous performance standards but also offer sustainability benefits, as tabular alumina can be recycled and repurposed.

| Application Area | Benefit | Future Trend |

|---|---|---|

| Ceramics | High thermal stability | Increased use in advanced ceramics |

| Refractories | Enhanced durability | Sustainable refractory formulations |

| Catalysts | Improved catalytic performance | Nano-coatings for better efficiency |

| Abrasives | Superior hardness | Smart abrasive systems |

| Insulators | Excellent electrical insulation | Innovations in high-voltage applications |