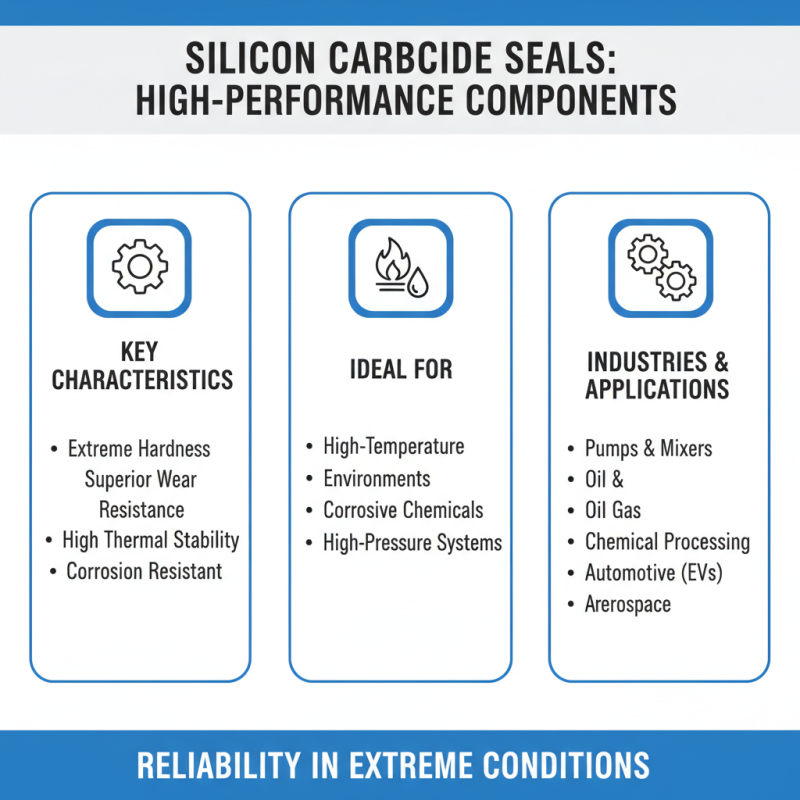

Silicon Carbide Seals are essential components in various industrial applications. These seals withstand extreme temperatures and harsh environments. Dr. Emily Chen, a renowned expert in materials engineering, states, "Silicon Carbide Seals are unmatched in durability and efficiency."

The unique properties of Silicon Carbide make these seals ideal for pumps and compressors. They resist wear and offer excellent thermal conductivity. However, the manufacturing process is intricate and requires precision. This raises the question of cost-effectiveness in production.

Despite their advantages, challenges remain. Companies must consider the balance between performance and budget constraints. Not all industries may benefit from Silicon Carbide Seals equally. Recognizing these nuances is vital for effective deployment. Understanding this complexity can enhance industrial reliability and performance.

Silicon carbide (SiC) is a remarkable compound composed of silicon and carbon. It’s known for its outstanding hardness and thermal conductivity. This material can withstand high temperatures, making it suitable for various applications. The unique properties of silicon carbide make it a favorite in industries requiring durability.

Silicon carbide is not just strong; it is also resistant to chemical corrosion. This means it performs well in harsh environments. Devices made from SiC can operate efficiently in extreme conditions. Additionally, they exhibit excellent electrical properties. This allows for its use in semiconductors and other electronic devices.

However, while silicon carbide is impressive, it has its challenges. The production process can be costly and requires careful handling. Quality control is essential, as impurities can reduce its performance. Engineers must balance these factors when designing components. There is still much to learn about optimizing silicon carbide’s properties for specific uses.

Silicon carbide seals are increasingly utilized across various industries for their unique properties. These seals exhibit excellent wear resistance and thermal stability. In the automotive sector, they help reduce friction and increase the lifespan of engines. This leads to improved fuel efficiency in vehicles. Manufacturing equipment also benefits from silicon carbide seals. They withstand harsh environments, ensuring reliable performance over time.

In the aerospace industry, silicon carbide seals play a vital role. They are used in jet engines, where temperatures and pressures are extreme. These seals enhance safety and efficiency. The chemical processing industry relies on silicon carbide for its resistance to corrosive substances. However, the manufacturing process can be expensive. This raises questions about balancing cost with performance.

Another notable application is in the renewable energy sector. Wind turbines and solar panels are beginning to incorporate silicon carbide seals. They help maintain the integrity of these systems against the elements. Despite their advantages, there is ongoing research to improve the production methods. Perfecting these seals could lead to broader applications and lower costs.

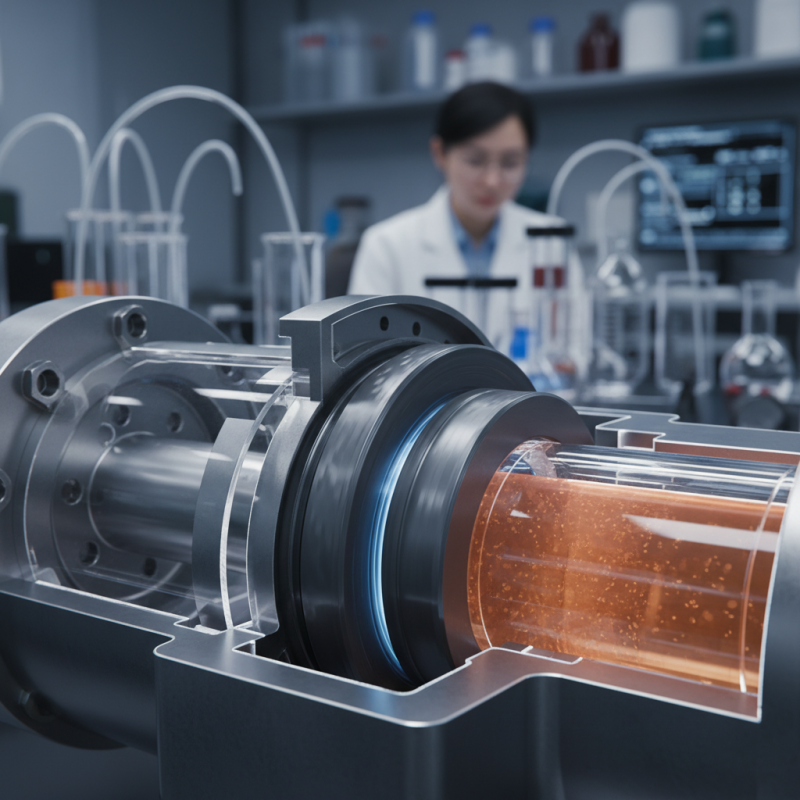

Silicon carbide seals are engineered to withstand extreme conditions. Their manufacturing involves complex processes, ensuring durability and reliability. Typically, these seals are produced through advanced techniques like sintering and precision machining. The choice of materials is critical, impacting performance.

The initial phase involves selecting high-purity silicon carbide powder. This powder is blended with additives to enhance properties. Then, it undergoes a high-temperature process. This creates a solid structure that can handle significant stress. A study showed that silicon carbide offers a wear resistance nearly three times better than traditional materials. This highlights its value in harsh environments.

Designing these seals requires a deep understanding of the application. Engineers must consider factors like temperature and chemical aggression. Additionally, simulations help predict performance. It's noteworthy that optimizing the design often requires multiple iterations, which can be time-consuming. Feedback and analysis play vital roles in refining these designs. Each iteration can uncover new challenges that may not have been initially obvious.

| Attribute | Details |

|---|---|

| Material | Silicon Carbide (SiC) |

| Operating Temperature | Up to 1600°C |

| Applications | Aerospace, Automotive, Industrial Pumps |

| Key Features | High Wear Resistance, Low Friction, High Oxidation Resistance |

| Benefits | Extended Lifespan, Reduced Maintenance Costs, Improved Efficiency |

| Manufacturing Process | Sintering, Machining, Surface Treatment |

| Design Considerations | Pressure Ratings, Temperature Limits, Compatibility with Fluids |

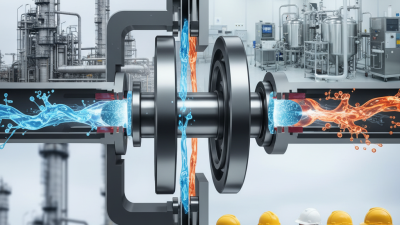

Silicon carbide seals are essential components in various industries. They are designed for high-performance applications, particularly where resistance to wear and high temperatures is crucial. The working mechanism of these seals relies on their unique material properties. Silicon carbide is hard and durable, making it ideal for sealing applications.

The interaction between two silicon carbide surfaces creates a tight seal. When in contact, they form a reliable barrier against liquids and gases. The seals operate effectively under extreme conditions, such as high pressure or harsh chemicals. This durability is not just theoretical; in real-world applications, many operators have reported challenges with wear over time.

Installation of silicon carbide seals requires precision. Even slight misalignment can lead to seal failure. This aspect can be frustrating but highlights the importance of careful engineering. Regular maintenance and inspections are necessary to ensure optimal performance. Understanding these factors is essential for extending the life of silicon carbide seals in challenging environments.

Silicon carbide seals are gaining popularity in various industries. Their advantages over traditional materials are noteworthy. These seals offer superior wear resistance. In fact, they can last up to five times longer than standard seals. This durability is crucial in applications with high friction and harsh environments.

Another key benefit is their thermal stability. Silicon carbide can withstand temperatures exceeding 1,600 degrees Celsius. This makes it ideal for applications in extreme conditions. Data from recent studies show that silicon carbide seals maintain their integrity under stress. In contrast, traditional materials can warp or degrade faster.

Cost implications also merit attention. While the initial investment may be higher, the long-term savings can be significant. For instance, reduced maintenance and replacement costs often balance out upfront expenses. However, companies need to consider performance expectations with silicon carbide. Not all applications will reap the same benefits. Therefore, careful analysis is crucial before transition decisions.