Silicon Carbide Seal is an innovative solution widely used in various industries. Its unique properties make it suitable for high-temperature and high-pressure environments. This material is known for its excellent wear resistance and durability. It can be found in applications ranging from automotive to aerospace.

Many companies have adopted Silicon Carbide Seals due to their reliability. However, challenges still exist in terms of production costs. Some manufacturers struggle to achieve the desired precision during fabrication. This affects overall performance in critical applications. Testing and improvements are essential.

In conclusion, while the potential of Silicon Carbide Seals is clear, the need for better production techniques is apparent. Ongoing research aims to address these concerns. Unlike traditional seals, this material promises longevity and efficiency under demanding conditions. The journey of developing Silicon Carbide Seals is just beginning.

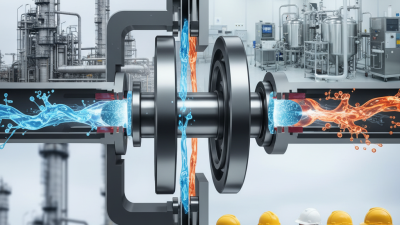

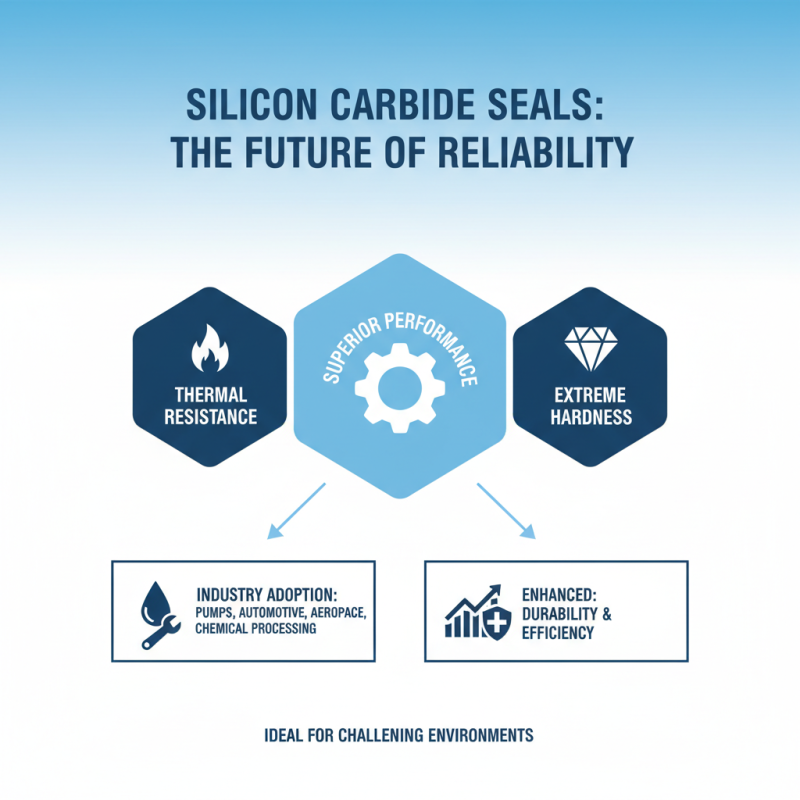

Silicon carbide (SiC) seals are engineered components widely used in various industries. These seals are made from a hard and durable ceramic material known for its exceptional mechanical properties. SiC combines high thermal conductivity with excellent wear resistance. This makes it suitable for applications in extreme environments, such as pumps and compressors.

In the automotive sector, SiC seals are increasingly vital for high-performance engines. A recent industry report suggests that they can enhance efficiency by up to 30%. This is significant considering fuel economy trends. In the semiconductor industry, SiC seals prevent contamination during processing. Their ability to withstand chemical attacks is crucial in this environment.

However, there are challenges. The manufacturing process can be costly and complex. Achieving the right balance between hardness and brittleness remains a concern. Some users report issues with improper fitting. Despite these drawbacks, the demand for silicon carbide seals continues to grow due to their unique properties.

Silicon carbide seals are increasingly used in various industries due to their unique properties. These seals resist wear and corrosion, making them ideal for harsh environments. Silicon carbide can operate at very high temperatures, up to 1,600 degrees Celsius. This makes it valuable in applications like aerospace and semiconductor manufacturing. According to a market report, the global silicon carbide market is projected to reach $5 billion by 2025, indicating rapid growth in demand.

One key property of silicon carbide is its hardness. It ranks around 9 on the Mohs scale. This hardness provides excellent durability in mechanical applications. Additionally, silicon carbide has a low thermal expansion coefficient. This helps maintain dimensional stability under thermal stress. However, fabrication can be challenging. Tolerances might not always meet industry standards, leading to potential issues in sealing performance. The material's brittleness also raises concerns during installation.

Another important aspect is its chemical resistance. Silicon carbide withstands many corrosive substances. This makes it suitable for chemical processing industries. Still, the high cost of silicon carbide can limit its application. Some industries might opt for cheaper alternatives, despite performance compromises. Balancing cost and performance remains a critical consideration.

Silicon carbide seals are becoming vital across various industries. Their unique properties, such as high hardness and thermal stability, make them ideal for harsh environments. These seals can withstand high temperatures and corrosive conditions. A crucial application is in the aerospace sector, where they ensure reliable sealing in engines. They help in maintaining efficiency and durability.

The automotive industry also benefits significantly from silicon carbide seals. These seals reduce friction and wear in high-performance vehicles. They contribute to better fuel efficiency and lower emissions. Additionally, the chemical processing industry utilizes these seals for their resistance to aggressive chemicals. This enhances the reliability of pumps and mixers.

Despite their advantages, certain challenges remain. The cost of silicon carbide can be higher than other materials. This aspect prompts industries to carefully evaluate their usage. Not every application requires such specialized seals. Choosing the right material is crucial for operational efficiency and cost management. Striking a balance between performance and cost remains a work in progress for many industries.

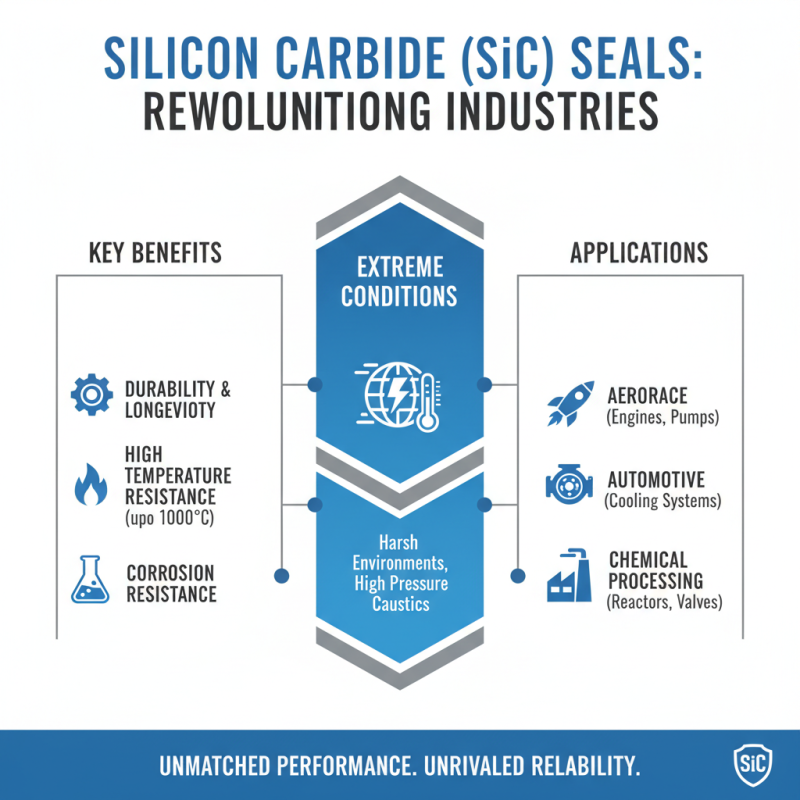

Silicon carbide (SiC) seals are revolutionizing industries by offering exceptional performance. These seals are known for their durability and resistance to high temperatures and corrosive environments. Their unique properties allow them to function effectively in extreme conditions, making them vital in applications such as aerospace, automotive, and chemical processing.

One of the main benefits of silicon carbide seals is their ability to withstand high pressures. Reports indicate that these seals can endure pressures up to 20,000 psi. This capability allows manufacturers to design more efficient systems. Moreover, SiC seals require less maintenance compared to traditional seals. This reduces downtime and minimizes operational costs, a significant advantage for businesses focused on efficiency.

**Tip:** When selecting seals for your application, consider the operating environment. Ensure that the seal material is compatible with any chemicals or temperatures it will encounter.

Another advantage is their low friction coefficient. SiC seals can improve energy efficiency in rotating equipment. This feature often results in reduced energy consumption. However, the initial cost of silicon carbide seals can be higher. Companies may need to evaluate the long-term savings against the upfront investment.

**Tip:** Evaluate your specific application needs before making a decision. Sometimes, a higher initial cost pays off with lower long-term maintenance and replacement expenses.

Silicon carbide seals are gaining traction across various industries. Their hardness and thermal resistance make them ideal for challenging environments. Many companies are exploring how these seals can enhance performance and reliability.

Future trends in silicon carbide seal technology focus on innovation in design and materials. This includes enhanced wear resistance and corrosion resistance, which are crucial for long-term effectiveness. Manufacturers are looking into hybrid materials that combine silicon carbide with other compounds. This shift could lead to more versatile applications in automotive, aerospace, and energy sectors.

Tips: When considering silicon carbide seals, evaluate the specific requirements of your application. Assess factors like temperature, pressure, and the chemical environment. Ensure that the chosen seal material aligns with your operational demands. This can prevent costly failures down the line.

As this technology evolves, some challenges remain. The manufacturing processes can be complex, leading to inconsistencies. Companies must be patient and invest time in refining their approaches. Feedback from actual use is essential to improve design and functionality over time.