Silicon carbide (SiC) is a compound that holds significant importance in various industries today. It is known for its exceptional thermal conductivity, high electric field breakdown strength, and resistance to thermal shock. According to a report by Market Research Future, the global silicon carbide market was valued at approximately $1.45 billion in 2020, with expectations to reach $5.25 billion by 2027. This rapid growth highlights its increasing relevance in sectors like automotive, electronics, and power generation.

Dr. Emily Warren, an expert in semiconductor materials, emphasizes the "Silicon Carbide Meaning" in modern technology. She states, "Silicon carbide is not just a material; it’s a cornerstone for future advancements in energy and electronics." This highlights its role in the development of energy-efficient devices. Its properties make SiC ideal for high-efficiency power conversion. However, challenges remain, such as production costs and scalability.

The significance of silicon carbide extends beyond its properties. It symbolizes innovation in materials science, pushing the limits of what is possible in device performance. As industries strive for sustainability, silicon carbide becomes more crucial. The potential for transformative applications invites both enthusiasm and skepticism. The road ahead remains complex, demanding continuous research and development.

Silicon Carbide (SiC) is a compound made of silicon and carbon. It possesses remarkable properties that set it apart in the semiconductor industry. SiC is extremely hard, rated 9 on the Mohs scale, making it ideal for abrasive applications. Its thermal conductivity is superior, reaching about 120 W/mK, which is much higher than traditional silicon.

With a breakdown voltage of approximately 3.5 MV/cm, SiC can operate at higher voltages. This makes it essential for power electronics in electric vehicles and renewable energy systems. Research indicates that SiC devices can achieve efficiencies exceeding 90%. These properties translate to reduced energy loss and improved device reliability.

Moreover, SiC's ability to function at extreme temperatures, up to 600°C, is a game-changer. In some cases, it can risk overheating, requiring careful management. Emerging studies highlight the need for better thermal management solutions. There’s a growing demand for SiC in the automotive sector and for industrial applications. However, there are concerns regarding supply chain sustainability. Addressing these issues is vital for leveraging SiC's full potential in future applications.

| Property | Value | Importance |

|---|---|---|

| Chemical Formula | SiC | The basic representation of Silicon Carbide's structure. |

| Molar Mass | 40.1 g/mol | Indicates the weight of one mole of SiC, important for stoichiometric calculations. |

| Melting Point | 2700 °C | High melting point makes it suitable for high-temperature applications. |

| Hardness (Mohs) | 9.0 | Second hardest material, excellent for abrasive applications. |

| Thermal Conductivity | 120 W/m·K | Efficient heat dissipation, ideal for electronic and power devices. |

| Electrical Conductivity | Semi-conductive | Used in high-power and high-frequency applications. |

| Applications | LEDs, power electronics, solar cells | Critical for modern technology development in semiconductor devices. |

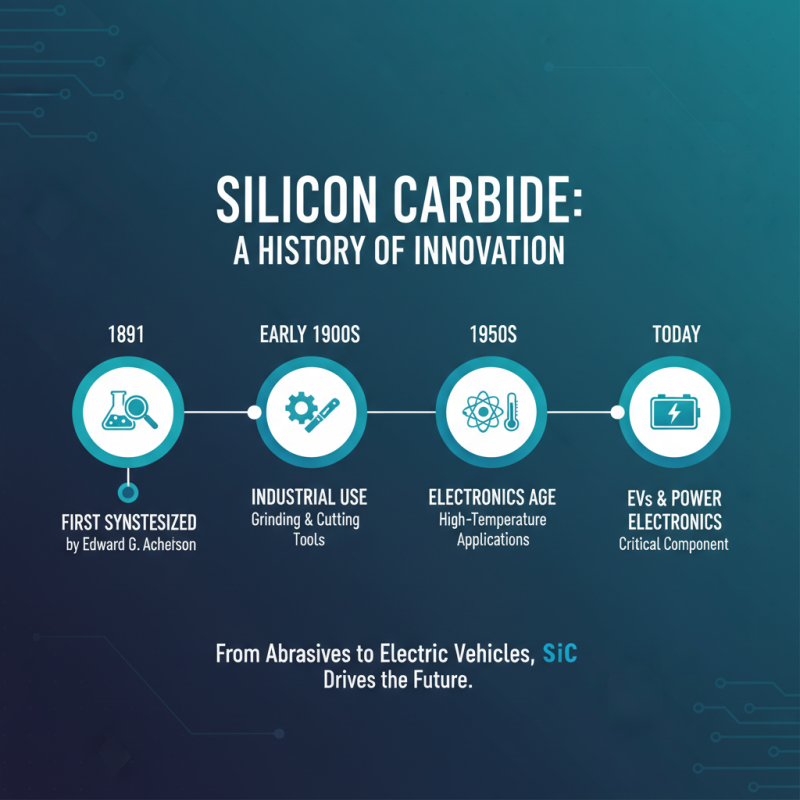

Silicon Carbide (SiC) has a rich history dating back to the late 19th century. It was first synthesized by Edward G. Acheson in 1891. Initially, its use was limited to grinding and cutting tools. However, its exceptional hardness attracted attention from various industries. By the 1950s, silicon carbide made its way into the electronics field, especially for high-temperature applications. The material's ability to withstand extreme conditions opened new doors. Today, SiC is a critical component in electric vehicles (EVs) and power electronics.

The industrial applications of silicon carbide are vast. In 2020, the global market for SiC was valued at approximately $1.60 billion, with projections suggesting it could reach $5.40 billion by 2027, growing at a compound annual growth rate (CAGR) of 19.2%. SiC's thermal conductivity makes it ideal for power devices. These devices are crucial for renewable energy systems, including solar inverters and wind energy. The switch from silicon to silicon carbide devices can result in efficiency improvements of up to 30%. However, the material's high production costs remain a challenge for widespread adoption.

SiC also finds application in the automotive sector, particularly for electric and hybrid vehicles. Its usage can enhance energy efficiency and reduce battery sizes. Despite its advantages, challenges persist related to reliability and fabrication. Researchers are exploring methods to improve SiC material characteristics and lower production costs. Continuous innovation is essential. The journey of silicon carbide is fascinating, filled with both achievements and hurdles.

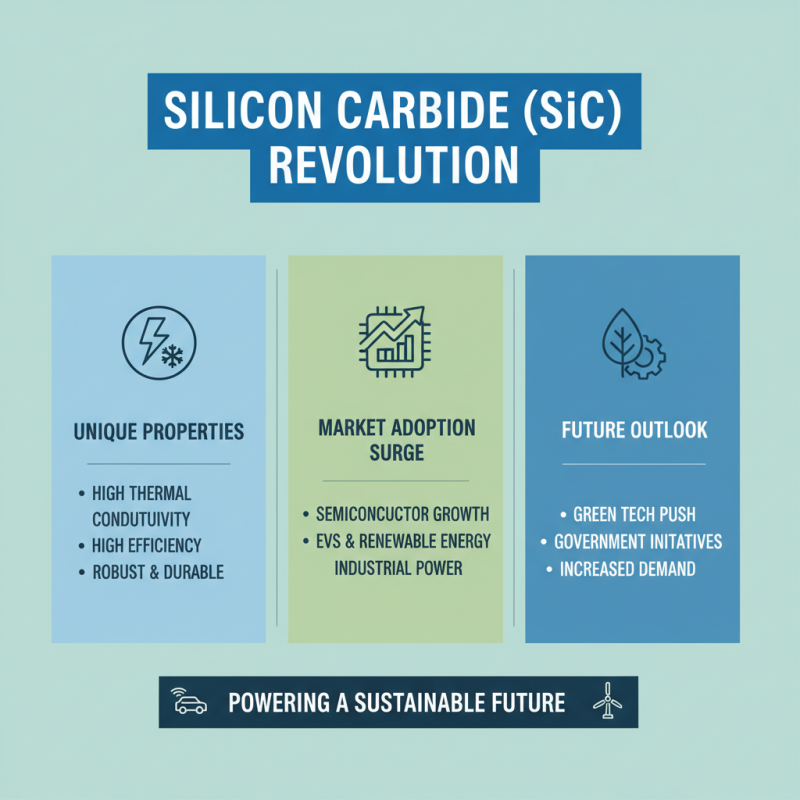

Silicon carbide (SiC) is gaining traction in various industries. Its unique properties, like high thermal conductivity and efficiency, make it desirable. Currently, the semiconductor market is witnessing a surge in SiC device adoption. Electric vehicles and renewable energy systems are key drivers for this increase. As governments push for greener technologies, the demand for SiC is likely to rise.

Market analysis also reveals shifting trends. The growth rate for SiC devices is impressive. It’s predicted to continue accelerating in the upcoming years. Challenges exist, such as supply chain constraints and manufacturing costs. Companies are exploring methods to enhance production efficiency. Despite these hurdles, many see SiC as a game-changer in power electronics.

Future projections indicate robust demand. Industries are looking to integrate SiC into various applications. Power conversion and energy efficiency are hot topics. As research advances, new possibilities will emerge. The trend points toward a strong reliance on silicon carbide. However, scrutiny over supply sources and ethical manufacturing remains essential. Balancing growth with responsibility is the next challenge.

Silicon carbide (SiC) is a semiconductor material known for its unique properties. Its ability to operate at high temperatures and voltages makes it invaluable in various applications. SiC devices can handle more power while reducing energy loss. This is crucial in industries focusing on efficiency and sustainability.

Another technical advantage of SiC is its thermal conductivity. This property allows devices to manage heat effectively, enhancing reliability. As systems become more compact, efficient heat dissipation becomes essential. However, the manufacturing processes for SiC are complex. Many challenges arise, including crystal growth and substrate quality. These challenges can impact the overall performance of SiC devices.

SiC's high breakdown electric field contributes to its robustness. This characteristic ensures reliable operation in extreme conditions. However, achieving optimal performance still requires significant research and development. Exploring ways to improve SiC technology is an ongoing challenge. There’s potential for innovation, but the path is not always clear.

This chart compares the technical advantages of Silicon Carbide (SiC) against traditional Silicon (Si) in key semiconductor performance metrics. SiC demonstrates significantly higher breakdown voltage, allows for higher operating temperatures, and has faster switching speeds, indicating its superior performance in demanding applications.

Silicon carbide (SiC) is a compound that has gained attention in various industries. Its unique properties make it essential for high-performance applications. However, manufacturing processes pose significant challenges. Achieving the desired purity and crystal quality is not easy. Many companies struggle with these aspects.

The production of silicon carbide often involves complex methods. These methods can be costly and time-consuming. Innovations are necessary to improve efficiency. Techniques like chemical vapor deposition show promise. Yet, these solutions can also lead to unexpected issues. Fluctuations in temperature or chemical reactions may affect quality.

Furthermore, the scalability of these new methods remains a concern. Some innovations work well on a small scale but fail to translate to larger operations. Companies must tackle these inconsistencies to meet growing demand. The quest for improvement in SiC production is ongoing. It highlights both the potential and limitations of current technologies.