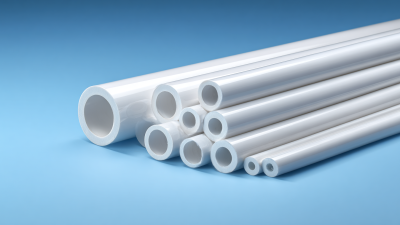

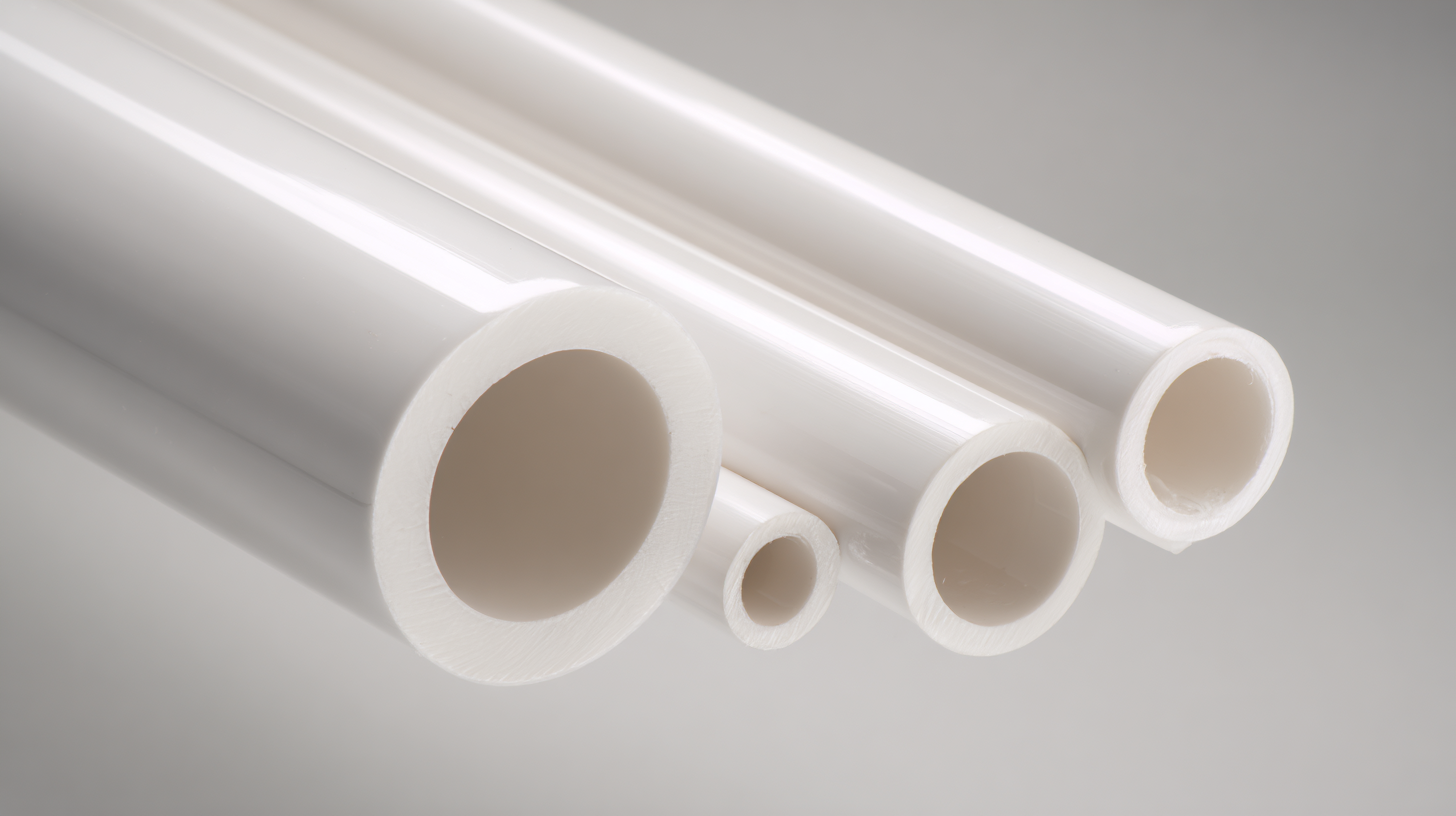

Zirconia Tubes are at the forefront of modern materials science, merging innovation with functionality across diverse applications. As industries evolve, the demand for advanced materials such as zirconia has surged, driven by its exceptional properties including high strength, thermal stability, and biocompatibility.

According to a recent market report by Grand View Research, the global zirconia market is expected to reach USD 1.12 billion by 2025, expanding at a CAGR of 6.9%. This growth is primarily fueled by its applications in sectors like dental implants, aerospace, and electronic devices. The remarkable versatility of Zirconia Tubes not only meets the rigorous demands of contemporary engineering but also paves the way for future advancements in various high-tech arenas.

Understanding the science behind these materials is crucial for leveraging their potential in innovation-driven markets.

Zirconia, known chemically as zirconium dioxide (ZrO2), plays a crucial role in the development of advanced materials. Its unique composition allows for impressive properties like high strength, wear resistance, and thermal stability. These characteristics make zirconia an excellent choice for applications ranging from dental ceramics to cutting tools and even aerospace components, where durability and reliability are paramount.

Tips for utilizing zirconia in your projects include focusing on the benefits related to its thermal insulation properties, which can lead to energy efficiency in high-temperature applications. Additionally, consider layering zirconia with other materials to enhance toughness and extend the lifespan of components. This strategic approach not only maximizes the advantages of zirconia but also contributes to innovative design solutions in modern technology.

The benefits of zirconia extend beyond performance; its biocompatibility makes it a preferred material in the medical field, particularly for implants and prosthetics. When selecting zirconia for advanced applications, ensure you assess the specific grades available to match your project’s requirements, as the properties can vary significantly based on formulations and processing techniques.

Zirconia tubes are emerging as a revolutionary material in both medical and industrial sectors, known for their exceptional durability, biocompatibility, and resistance to corrosion. In medical applications, zirconia tubes are increasingly utilized in

dental implants, prosthetics, and various surgical instruments due to their ability to withstand the harsh conditions of the human body.

Reports indicate that the demand for such advanced materials is surging, with the North America Copper Tubes Market projected to reach USD 3.44 billion by 2030, suggesting a trend where high-performance materials are becoming more integral to healthcare solutions.

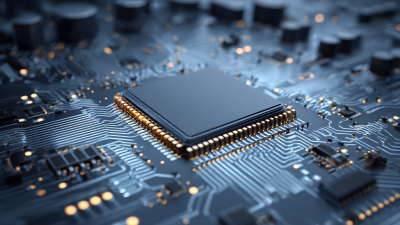

Innovative manufacturing techniques play a crucial role in enhancing the performance of zirconia tubes, which are widely used in various modern applications ranging from dental implants to aerospace components. Recent advancements in additive manufacturing and sintering processes have significantly improved the density and mechanical properties of zirconia, resulting in tubes that exhibit exceptional strength and durability. According to a report by SmarTech Analysis, the global market for advanced ceramic materials, including zirconia, is expected to reach $20 billion by 2025, driven by these innovations.

One key technique is the use of 3D printing for producing zirconia tubes. This method allows for complex geometries that traditional manufacturing processes struggle to achieve, providing a tailored fit for specific applications. Additionally, advancements in sintering technology have reduced the time and energy required to achieve optimal densities in zirconia components. Research shows that tubes manufactured through these innovative techniques can have up to 30% improved fracture toughness compared to conventionally produced ones.

Tips: When selecting zirconia tubes for your application, consider the manufacturing method as it significantly impacts the material properties. Additionally, ensure that the supplier provides detailed information on the fabrication process and associated performance metrics to make an informed decision. Understanding the specific requirements of your usage will also help in choosing the right innovation for optimal performance.

Zirconia tubes have emerged as a leading choice in advanced material applications due to their superior properties compared to traditional materials. Unlike metals and polymers, zirconia offers exceptional strength, high thermal resistance, and excellent biocompatibility, making it an ideal candidate for applications ranging from biomedical devices to high-temperature industrial processes. Its resistance to corrosion and wear significantly extends the lifespan of components, reducing the need for frequent replacements and maintenance, which is a common issue with conventional materials.

When comparing zirconia tubes to traditional materials such as stainless steel or plastic, several key advantages become apparent. For instance, while stainless steel may offer good mechanical strength, it lacks the necessary biocompatibility for direct use in medical implants, where zirconia excels. Additionally, traditional plastics can suffer from temperature limitations and chemical degradation, whereas zirconia maintains its integrity under extreme conditions. This comparative analysis highlights the ongoing shift towards zirconia in modern applications, driven by the need for materials that not only meet performance expectations but also advance technological innovation in various fields.

| Property | Zirconia Tubes | Traditional Materials |

|---|---|---|

| Density (g/cm³) | 6.0 | 7.8 (steel) |

| Tensile Strength (MPa) | 1200 | 400 (steel) |

| Thermal Conductivity (W/mK) | 2.5 | 50 (copper) |

| Corrosion Resistance (pH range) | 3-14 | 5-9 |

| Application Areas | Biomedical, Aerospace | Construction, Automotive |

| Cost ($/kg) | 150 | 3 |

The future of zirconia research and development, particularly in advanced technologies, is a focal point of ongoing scientific inquiry and commercial interest. As industries increasingly adopt zirconia for its exceptional properties, including high strength and corrosion resistance, innovations in this material are paving the way for enhanced applications. In dental implantology, for instance, zirconia-based materials are being explored for their biocompatibility and aesthetic appeal, contributing to a projected market growth from USD 435.94 million in 2025 to approximately USD 902.42 million by 2034. These advancements are likely to improve patient outcomes and treatment options in dentistry.

Moreover, research in catalysts and membranes for water electrolyzers is another key area where zirconia is making strides. The development of efficient membranes and catalytic materials is essential for optimizing the production of green hydrogen, a clean energy source. As research continues to evolve, the potential applications of zirconia in renewable energy technologies are expected to grow, driving innovation in both material performance and sustainability. The dynamic nature of zirconia research underscores its critical role in addressing current technological challenges and its promise for future advancements across various industries.