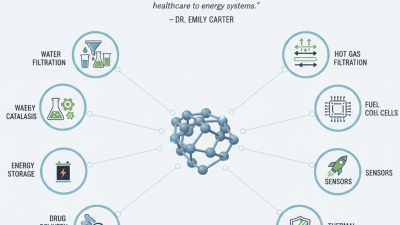

Porous Ceramic materials have gained attention in various fields. Their unique properties can enhance performance in numerous applications. This introduction will explore the significance of Porous Ceramic tips.

The structure of Porous Ceramic allows for improved gas and liquid flow. This feature is vital in filtration systems and catalytic converters. Additionally, these materials offer excellent thermal stability. Yet, the production of Porous Ceramic can be complex. Manufacturers often face challenges ensuring uniform porosity. Variations can impact overall effectiveness.

In practical use, Porous Ceramic tips can enhance efficiency. They reduce waste and optimize performance in devices. However, some applications may not achieve desired results. Understanding the nuances in their use is crucial. Overall, while the potential of Porous Ceramic is vast, there's room for improvement and innovation.

Porous ceramics are fascinating materials defined by their unique structure. These ceramics contain tiny holes that create a lightweight yet strong body. Their porous nature allows for excellent thermal and acoustic insulation. They also exhibit high resistance to chemical attack, making them ideal for various applications. Understanding these properties can help in selecting the right material for specific uses.

When choosing porous ceramic tips, consider the intended application. For example, they work well in filtration systems. The pores allow particles to be trapped while allowing fluids to pass through. Additionally, these tips can enhance performance by providing better adhesion in certain contexts. The key is to ensure compatibility with the substances they will encounter.

There are trade-offs to consider. Porous ceramics can be delicate, and their strength may vary based on density. Some applications might not utilize their full potential. Reflecting on these aspects can lead to better decisions when integrating them into projects. The performance of porous ceramics often depends on meticulous design choices.

| Property | Description | Applications |

|---|---|---|

| Porosity | The volume fraction of voids in the material, which affects density and permeability. | Used in filtration systems and as catalyst supports. |

| Thermal Stability | Ability to retain mechanical properties under temperature variations. | Used in thermal insulators and kiln furniture. |

| Chemical Resistance | Resistance to chemical reactions and degradation. | Utilized in chemical reactors and waste treatment. |

| Mechanical Strength | Ability to withstand stress without failure. | Applicable in load-bearing components and structural applications. |

| Lightweight | Reduced weight compared to traditional ceramic materials. | Suitable for aerospace and automotive components. |

Porous ceramic tips have emerged as an innovative solution for various industries. Their unique structure allows for improved filtration and separation efficiency. According to recent market reports, the demand for porous ceramic materials in the filtration sector is projected to exceed $1 billion by 2025. This highlights their growing importance in applications like water treatment and air purification.

The use of porous ceramic tips in biomedical applications is particularly intriguing. They can support cell growth, making them essential in regenerative medicine. A study showed that using these ceramics increased cell proliferation rates by 25%. However, challenges remain regarding their integration into existing medical systems. Companies must find ways to optimize manufacturing processes to reduce costs while maintaining performance.

In the energy sector, porous ceramics are finding applications in fuel cells and batteries. Their ability to withstand high temperatures is crucial. Reports indicate that this market could see a compound annual growth rate of 15% over the next five years. Yet, despite their potential, there are concerns about long-term durability and scalability. Industries need to address these issues to harness maximum benefits.

Porous ceramic tips offer unique benefits that can significantly enhance performance in various applications. Their structure allows for better airflow and pressure distribution, creating a smoother, more efficient output. Users often notice improved results, particularly in settings where precision is crucial. The lightweight nature of these tips also contributes to their appeal, making them easy to handle.

Another advantage lies in their durability. Porous ceramics resist wear and tear better than many alternatives. This longevity can save resources and reduce the need for frequent replacements. However, not every application benefits from porous designs. Sometimes, stronger materials might be more effective, depending on specific needs. This raises questions about when to choose porous options.

Additionally, porous ceramic tips can lead to unsatisfactory performance if not used correctly. If the fit is improper, for instance, the efficiency gains may diminish. Users must also consider maintenance, as the porous structure can collect residues. Regular cleaning is essential to maintain optimum performance. Embracing these details can make a significant difference in outcomes.

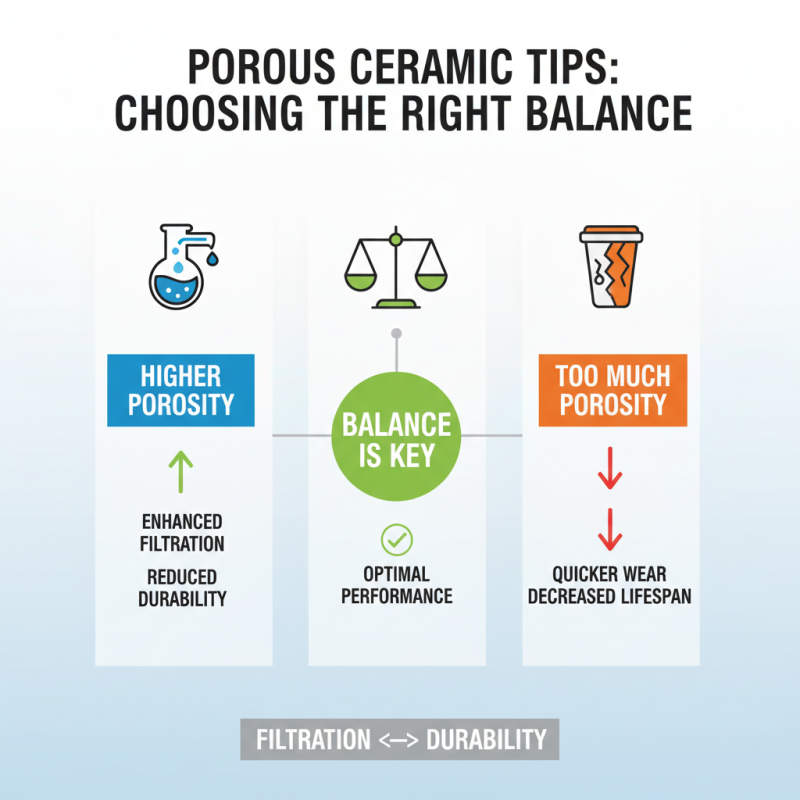

When choosing porous ceramic tips, there are various factors to consider. One important aspect is the porosity level. Higher porosity can enhance filtration but may reduce durability. Balance is key; too much porosity might lead to quicker wear.

Another factor is the application type. Specific tasks may require different tip shapes or sizes. For instance, fine tips can improve precision in detailed work. However, they may clog easily. It's crucial to reflect on your usage patterns to avoid frustration.

Material composition also plays a significant role. Some ceramics resist heat better than others. Consider the working environment. Will the tips face extreme temperatures? Mixed reviews exist about durability in high-stress situations. Testing under real conditions can provide valuable insights. While experimentation may involve some trial and error, it leads to better choices for your needs.

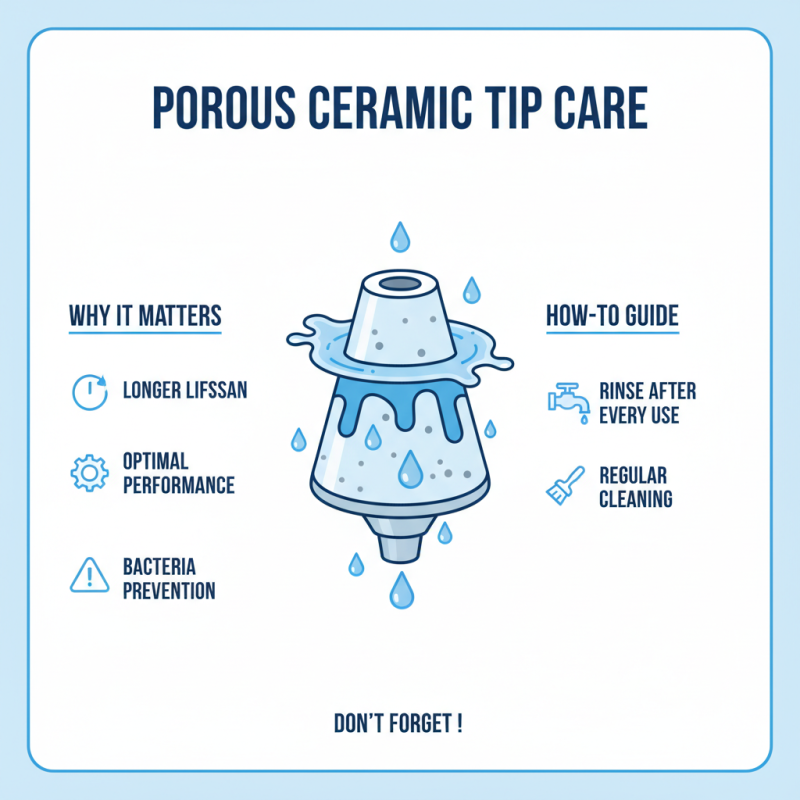

Proper maintenance of porous ceramic tips is essential for enhancing their lifespan and performance. Regular cleaning is crucial. Studies show that unmaintained tips can lose effectiveness over time. It's recommended to rinse these tips after every use. Some users forget this step, leading to residue buildup. This can hamper performance and create a breeding ground for bacteria.

In addition to cleaning, storage conditions matter. Porous materials can absorb moisture if not stored properly. Keeping them in a dry environment extends their life. According to recent reports, improper storage can reduce the lifespan of ceramic tips by up to 30%. Users might overlook this fact, resulting in frequent replacements. The ideal climate for storage is cool and dry, with low humidity levels.

Inspecting these tips for wear is also vital. Regular checks for cracks or chips can help identify failure points early. Ignoring wear and tear can lead to poor performance and safety hazards. Some users avoid this practice, which is a missed opportunity for preventive care. Regular attention and proactive measures can ensure that porous ceramic tips continue to perform at their best.