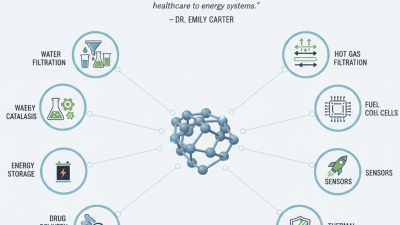

Porous ceramic is a unique material with a wide range of industrial applications. Dr. Emily Zhang, a leading expert in ceramic engineering, states, “Porous ceramics combine lightweight properties with excellent thermal insulation.” This characteristic opens up many opportunities in industries like aerospace, automotive, and biomedical.

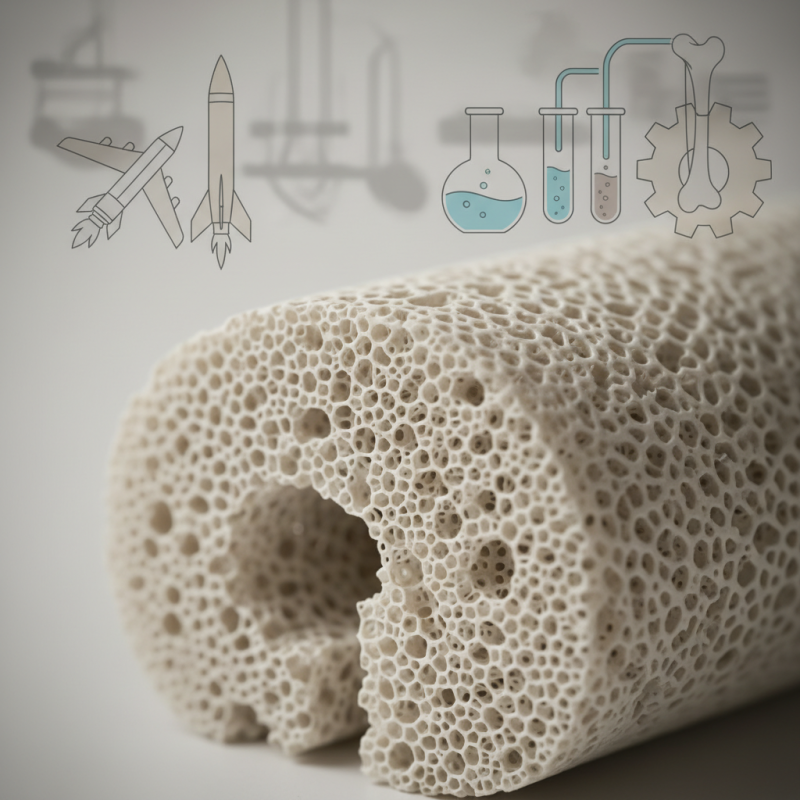

In the aerospace sector, porous ceramics are used for thermal barriers. These materials help reduce weight while maintaining strength. They also serve as filters in chemical processing. Here, their porosity plays a crucial role by separating substances effectively. However, challenges remain in optimizing the production processes for consistent quality.

In the biomedical field, porous ceramics are utilized in bone grafts and dental implants. Their biocompatibility is promising, but researchers still seek to improve long-term performance. The potential of porous ceramics is vast, yet their development needs continuous reflection and innovation. The journey of understanding and enhancing porous ceramics is ongoing, as industries push forward into unexplored territories.

Porous ceramics are materials with interconnected voids, providing unique structural and functional features. They are typically composed of a ceramic matrix that is engineered to achieve specific porosity levels. The porosity can range from 5% to over 80%, depending on the intended application. This characteristic allows for improved lightness and thermal insulation.

In industry, these materials find applications in filtration, thermal barriers, and catalyst supports. Recent reports indicate that the global porous ceramics market is expected to reach USD 700 million by 2025, growing at a CAGR of 12.5%. This growth reflects increasing demand in sectors like aerospace and environmental engineering. Porous ceramics are also valued for their ability to withstand high temperatures and corrosive environments, making them suitable for various challenging applications.

However, manufacturing porous ceramics can be complex. The processing requires precise control over porosity and pore distribution, which can lead to variability in product quality. Not all produced ceramic components meet the desired specifications. This inconsistency poses challenges for industrial adoption. Companies must account for these factors during the design phase to ensure optimal performance and reliability in their applications.

Porous ceramics are unique materials with many industrial applications. Their manufacturing processes are essential for achieving desired properties. Each method has its challenges, yet they contribute greatly to the final product's functionality.

One common technique is the plastic forming process. This involves mixing ceramic powders with water and additives to create a pliable paste. The paste is then shaped into the desired form. However, controlling the moisture content is tricky. Too much water can lead to defects, while too little makes shaping difficult. Additionally, achieving uniform density can be a challenge.

Another method is sintering. This process involves heating the shaped ceramic to high temperatures. It causes the particles to fuse together. However, balancing temperature and time is vital. Too high a temperature can lead to deformation, while too low may not achieve proper bonding. Each method requires careful consideration of materials and conditions, highlighting the intricacies in producing porous ceramics.

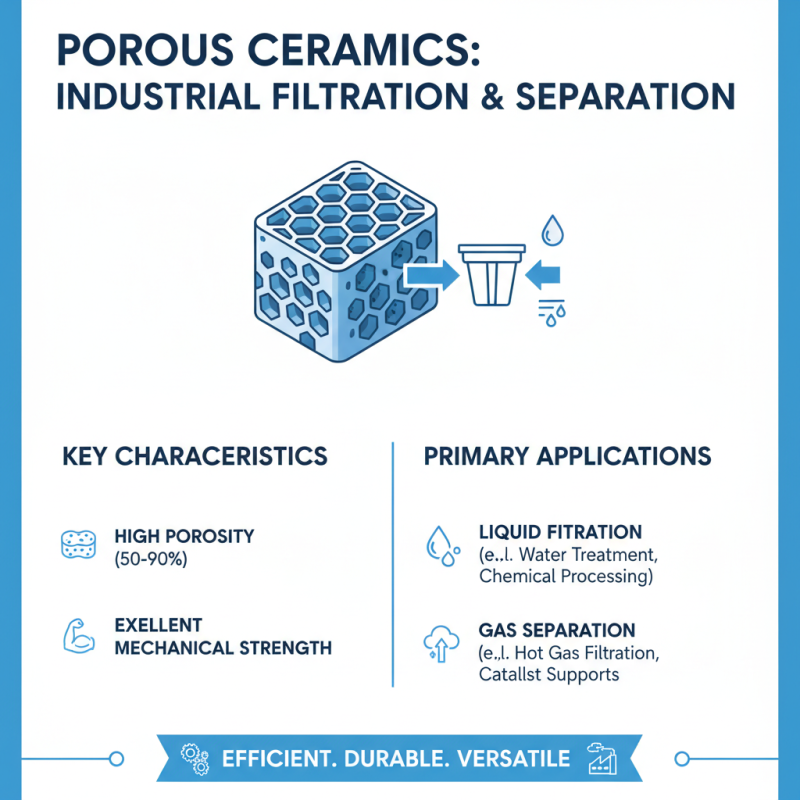

Porous ceramics have gained significant attention in industrial applications, especially in filtration and separation processes. These materials are characterized by their high porosity and excellent mechanical strength. Their unique structure allows for efficient separation of particles and contaminants from liquids and gases.

In filtration, porous ceramics can remove fine particles and impurities. They ensure high flow rates while maintaining structural integrity. This makes them ideal for water purification systems and chemical processing. The uniformity of pore size is critical. It helps achieve consistent filtration performance. However, achieving the right balance of porosity and strength can be challenging.

**Tip:** When selecting porous ceramics for your applications, consider factors like pore size and shape. These directly impact filtration efficiency.

Porous ceramics also play a vital role in gas separation. They can selectively filter gases based on molecular size. Industries like petrochemicals and pharmaceuticals benefit from this. Yet, the production process for these ceramics isn't flawless. Some batches might have inconsistent pore structures. Regular testing and quality control are essential to ensure performance.

**Tip:** Don’t overlook the importance of prototypes. Testing different designs can reveal unexpected issues early.

Porous ceramics play a crucial role in biomedical engineering. These materials possess unique properties that make them ideal for various applications within the field. Their interconnected pore structure allows for improved biocompatibility and the ability to support cell growth. This is particularly beneficial for bone tissue engineering.

Creating scaffolds for bone regeneration is one significant application. These scaffolds provide a supportive framework for new bone cells to grow. They mimic the natural bone structure, which helps in effective healing. However, making them with the right pore sizes and distribution can be challenging. Sometimes the porosity is either too high or too low, affecting their functionality.

Tips: Regularly evaluate the pore structure during manufacturing. Small adjustments can lead to improved outcomes. Additionally, consider the materials used. The choice of raw materials can significantly influence the properties of the final product, including its strength and biocompatibility. Professionals in the field should regularly collaborate with researchers to stay updated on advancements and insights, as this field is rapidly evolving.

Porous ceramics are gaining traction in various industries due to their unique properties. These materials are lightweight, strong, and have excellent thermal resistance. Recent advancements highlight their use in filtration and catalysis. The global porous ceramic market is projected to reach $3.5 billion by 2027, increasing at a CAGR of 8.2%. This growth suggests a rising demand for eco-friendly materials.

Innovations in manufacturing techniques are key. 3D printing technologies allow for intricate designs and precise control of pore structures. This opens doors for applications in biomedicine and energy sectors. Studies indicate a 25% increase in efficiency in catalytic converters using advanced porous ceramics. However, challenges remain in scaling production and ensuring consistency in quality.

Research is ongoing into the use of natural materials for creating porous ceramics. These developments could lead to more sustainable options. Yet, the industry faces hurdles in material durability and performance in extreme conditions. Addressing these issues is essential as the demand for high-performance ceramics continues to rise.

| Application | Description | Material Type | Key Properties | Future Trends |

|---|---|---|---|---|

| Filtration | Used for water and air purification, allowing fine particles to be removed. | Alumina-based | High porosity, chemical resistance | Development of self-cleaning filters |

| Catalysis | Supports catalysis process in chemical manufacturing. | Silica-based | High surface area, thermal stability | Integration with nanomaterials for enhanced efficiency |

| Biomedical | Used in bone implants and tissue engineering scaffolds. | Calcium phosphate | Biocompatibility, bioactivity | Biodegradable options for temporary implants |

| Thermal Insulation | Effective thermal barriers in high-temperature processes. | Zirconia-based | Low thermal conductivity, high melting point | Development of lighter weight materials |

| Energy Storage | Used in fuel cells and batteries for efficient energy storage. | Porous carbon | High conductivity, large surface area | Innovations in conductive additives |