Choosing the right Zirconia Rods can significantly impact your projects. These rods are known for their strength and durability. They are widely used in various applications, such as ceramics and electronics.

However, selecting the best rods involves understanding specific needs. Consider factors like size, strength, and purpose. Many underestimate the importance of the right specifications. Often, buyers focus on price rather than quality. This can lead to unsatisfactory results in the long term.

Research is crucial before making a decision. Evaluate different brands and their offerings. Read reviews and seek recommendations from professionals. Sometimes, the most well-known brands may not suit your particular requirements. Taking the time to reflect on your needs can make a big difference in your choice.

When choosing zirconia rods, several key factors must be considered. First, the grade of zirconia matters significantly. Different grades offer varying mechanical properties. For instance, Y-TZP (Yttria-Stabilized Tetragonal Zirconia Polycrystal) is commonly used for its toughness and wear resistance. Reports indicate that Y-TZP exhibits high bending strength, often exceeding 1,200 MPa.

Next, tolerance levels are crucial. Precision is vital for applications in sectors like orthodontics or dental restorations. Small discrepancies can lead to significant issues in fit and durability. Consider your project’s needs. High tolerance means better outcomes but can be more expensive.

**Tip:** Always specify your application when consulting suppliers for zirconia rods. Clarifying use will help in getting tailored recommendations.

Finally, the rod's diameter and length should align with your application. A too-thick rod may affect weight distribution, while a too-thin rod might lack strength. Additionally, reflect on the logistics of handling these rods. Transporting lengthy rods can be cumbersome and inadequate packaging could lead to damage.

**Tip:** Ensure to factor in shipping and storage when planning your procurement process. Keep your workspace organized to avoid damage.

| Property | Importance | Recommended Range | Notes |

|---|---|---|---|

| Density | High | 6.0 g/cm³ - 6.1 g/cm³ | Affects weight and performance. |

| Thermal Conductivity | Medium | 2.5 W/m·K - 3.0 W/m·K | Essential for high-temperature applications. |

| Flexural Strength | High | 600 MPa - 1200 MPa | Critical for mechanical stability. |

| Color | Low | Various | Affects aesthetic appeal. |

| Purity | Very High | 99.8% - 99.9% | Impurities can affect performance. |

| Size / Diameter | Medium | 1 mm - 20 mm | Depends on specific application needs. |

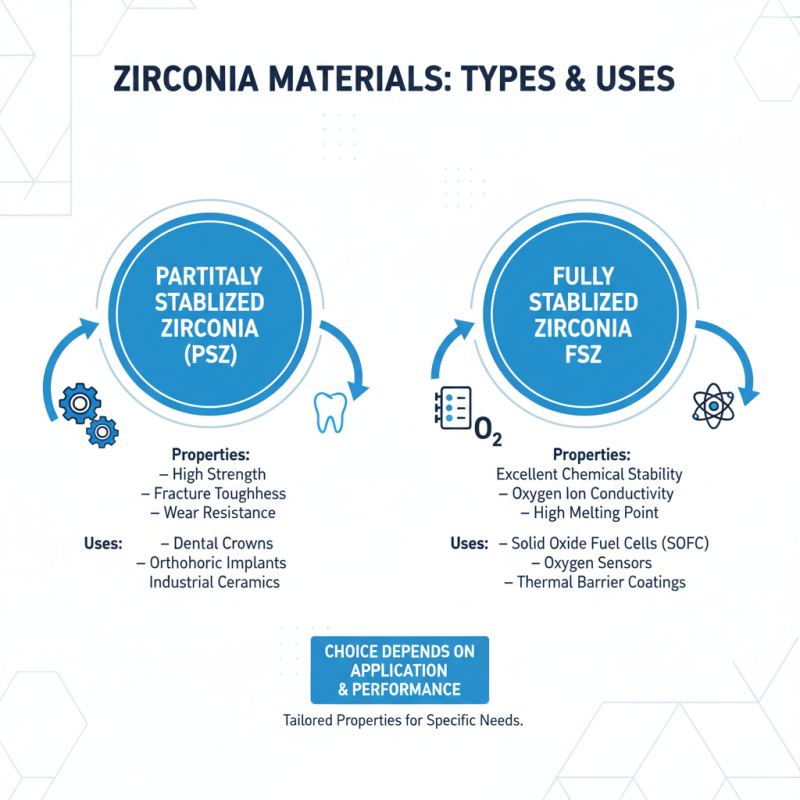

Zirconia materials come in various forms, each tailored for specific applications. The choice depends on the intended use and performance requirements. Some common types include partially stabilized zirconia and fully stabilized zirconia. Each type has its unique properties and characteristics, which influence their performance under different conditions.

Partially stabilized zirconia is known for its high strength and toughness. It is ideal for applications in dental crowns and cutting tools. This material can withstand significant mechanical stress. On the other hand, fully stabilized zirconia offers superior chemical resistance but can be more brittle. It is often used in high-temperature environments. Understanding these differences is crucial for selecting the best option.

However, selecting the right zirconia rod is not always straightforward. Users may find that their initial choices don't meet their expectations. It may take time to gauge performance under real operating conditions. Testing different types and observing their behavior is essential. This exploration can lead to better decisions and improved outcomes in various applications.

Choosing the right size and shape of zirconia rods can significantly impact their performance. In many applications, the dimensions influence strength and functionality. Larger rods may offer better stability but can be cumbersome to handle. Conversely, smaller rods can provide precision but may lack durability under stress. It’s essential to assess the specific demands of your project before making a choice.

Consider the environment where the rods will be used. For instance, thicker rods might be preferable in high-stress situations. They can resist cracking and wear more effectively. However, if your application requires intricate designs, thinner rods may be necessary. This choice could lead to issues if the rods are too fragile. It’s a delicate balance. Test different sizes and shapes to find the best fit. Keep an open mind to adjustments. Don't hesitate to questions your initial choices. The right dimensions can enhance the functionality of your work profoundly.

When choosing zirconia rods, assessing thermal and mechanical properties is critical. Zirconia is known for its high thermal stability. It can withstand temperatures up to 2,500°C. This makes it suitable for high-temperature applications. For instance, studies have shown that zirconia retains its strength even under extreme heat. Yet, not all zirconia rods perform equally under stress.

Mechanical properties are equally important. The flexural strength of zirconia can vary widely. Reports indicate values between 800 MPa to over 1,200 MPa. The specific composition of the zirconia can influence these results. You may find that some rods crack under pressure while others do not. It’s vital to analyze the material's toughness and hardness. In some scenarios, a rod may seem perfect but fails during rigorous use.

Paying attention to these properties helps in selecting suitable zirconia rods. Thermal conductivity also matters. A lower thermal conductivity can mean better insulation. On the other hand, higher conductivity might be necessary for some applications. Understanding these nuances can greatly impact your project's success. It's a complex decision, often requiring multiple tests and reflections.

This chart compares the thermal conductivity, flexural strength, and hardness of two different types of zirconia rods. The properties are crucial for selecting the right zirconia rod for your specific needs and applications.

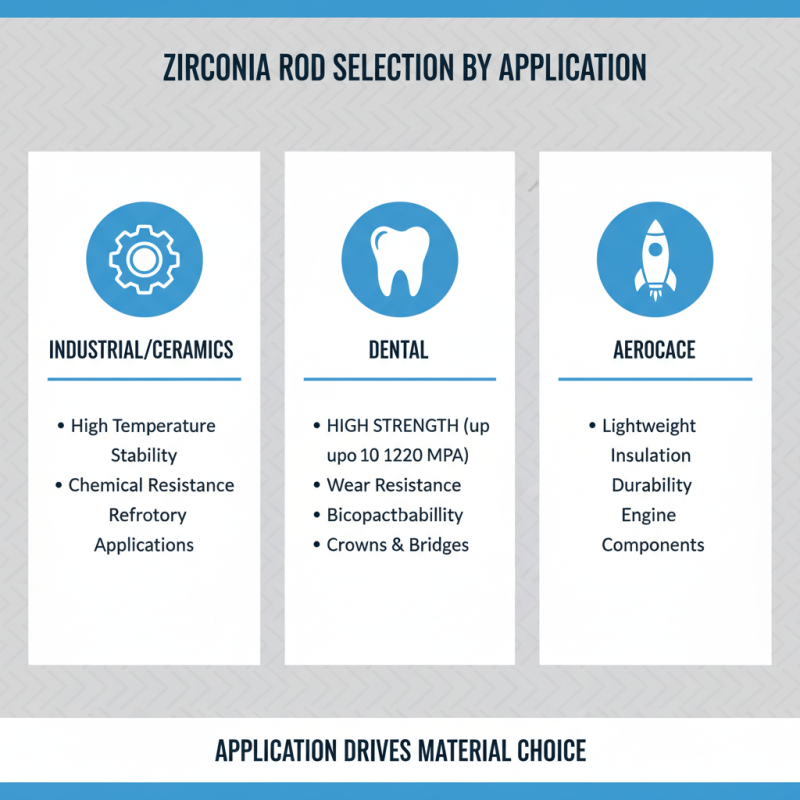

When selecting zirconia rods, the application plays a crucial role in decision-making. Different industries, such as ceramics, dental, and aerospace, have unique requirements. For example, the dental sector demands high strength and wear resistance. A study indicates that zirconia can withstand a bending strength of up to 1,200 MPa, making it ideal for dental applications.

In the ceramics field, thermal stability is vital. Zirconia rods are preferred for their low thermal conductivity, which helps in maintaining performance under high temperatures. Reports show that zirconia retains its properties even when exposed to extreme conditions. However, users should consider the limiting factors such as brittleness.

Aerospace applications require rigorous testing. Here, tolerances and precision machining are crucial. Notably, zirconia can be challenging to grind and shape. This may lead to higher production costs. Users often need to reflect on the balance between cost and performance. Understanding the specific demands of each application is imperative in choosing the right zirconia rods.