When it comes to protecting surfaces, Aluminium Ceramic Coating stands out for its durability. This advanced coating offers a hard, resilient layer against wear and corrosion. Applying it correctly can significantly improve longevity.

To achieve maximum durability, proper preparation is key. Surfaces must be cleaned meticulously to ensure adhesion. Even minor imperfections can affect the coating’s effectiveness. The application process requires attention and care. It’s not just brush and go; timing and environmental conditions matter.

While Aluminium Ceramic Coating provides excellent protection, it’s essential to acknowledge potential issues. Incorrect application can lead to peeling or flaking. Reflecting on these challenges helps achieve better results. Understanding the importance of each step will lead to a long-lasting protective surface.

Aluminium ceramic coating is a game changer in surface protection. It enhances durability significantly, making surfaces resistant to abrasion and corrosion. A recent report from an industry study indicates that coated surfaces can withstand wear up to five times longer than untreated counterparts. This durability reduces maintenance costs in the long run.

When considering the benefits, the heat resistance of aluminium ceramic coating cannot be overlooked. This coating can endure temperatures exceeding 1,000 degrees Celsius. That makes it appealing for various applications, from automotive to aerospace. However, this level of heat resistance can be tricky to achieve uniformly. Uneven application or surface preparation may compromise the coating's effectiveness.

Adhesion is another critical factor. For best results, the surface must be meticulously prepped. Any contaminants can lead to peeling or chipping. Reports suggest that a well-prepared surface can enhance adhesion by 30%. This number is compelling, but achieving the ideal preparation remains a challenge for many. Attention to detail is crucial. Imperfections in the application process may arise, affecting the long-term performance of the coating. Regular inspection is essential to ensure optimal durability.

Preparing the surface is crucial before applying aluminium ceramic coating. Start by cleaning the surface thoroughly. Remove dust, grease, and any contaminants. Use a suitable degreaser to ensure a clean base. A clean surface allows better adhesion of the coating.

Next, inspect for imperfections. Look for scratches, rust, or old coatings. Repair any damage with appropriate fillers or sand down rough areas. You want a smooth and even surface. This step can often be overlooked, leading to issues later.

After repairs, sand the surface lightly. Use fine-grit sandpaper to create a texture. This promotes better bonding of the coating. However, care is needed not to oversand. Over-sanding can lead to uneven application. Finally, wipe the surface again, making sure it’s free from debris. Your preparation is key for a durable finish.

Applying aluminium ceramic coating requires precision and the right techniques. Achieving an even coat is crucial for optimal performance. Research indicates that uneven application can lead to weak spots, reducing durability by up to 30%. It's essential to maintain a consistent thickness throughout the surface. Professionals recommend a thickness range of 20-30 microns for maximum protection.

Proper surface preparation is critical. This includes cleaning and sanding to reduce imperfections. Any debris can lead to bumps in the coating layer. Such imperfections should not be overlooked. They can significantly compromise the coating's effectiveness. Studies show that prepped surfaces yield a 25% increase in adhesion strength.

Techniques like spray application allow for better control over the coating process. A steady hand and even motion help in achieving the desired results. However, humidity and temperature can affect drying times. Monitoring these conditions ensures optimal curing. Mistakes can happen, and they serve as learning opportunities. Reflections on previous applications may highlight areas for improvement. It's a constant journey towards mastering the art of coating.

| Application Technique | Description | Recommended Tools | Estimated Time | Durability Impact |

|---|---|---|---|---|

| Surface Preparation | Clean the surface thoroughly to remove oils and debris. | Degreaser, microfiber cloths | 30 minutes | High |

| Masking | Cover areas that should not be coated to avoid overspray. | Masking tape, plastic sheets | 20 minutes | Medium |

| Coating Application | Apply a uniform layer of coating using a spray gun. | HVLP spray gun, personal protective equipment | 1 hour | Very High |

| Curing | Allow the coating to cure completely according to product guidelines. | Heat lamp or oven (if applicable) | 3-24 hours | Maximum |

| Final Inspection | Inspect for even coverage and any defects. | Visual inspection tools | 15 minutes | Affected by defects |

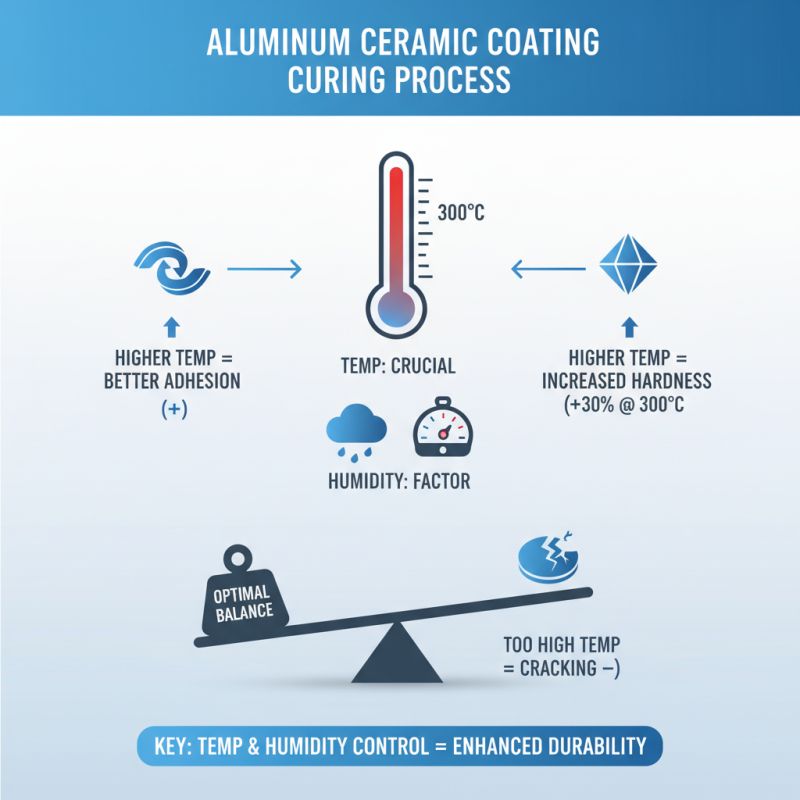

The curing process of aluminium ceramic coatings is crucial for enhancing durability. Temperature and humidity play a significant role here. Studies show that curing at higher temperatures leads to better adhesion and hardness. For example, coatings cured at 300°C exhibit a hardness increase of about 30% compared to those cured at room temperature. However, achieving the optimal balance is tricky; too high temperatures can cause cracking.

Finishing processes also matter greatly. A well-executed finishing can add to the coating's longevity. Techniques such as polishing and surface grinding can improve surface smoothness, reducing the likelihood of wear. Industry reports suggest that smoother surfaces can reduce friction by up to 25%. Nevertheless, over-polishing may compromise the coating's thickness, risking durability. Finding the right techniques requires careful experimentation and reflection. Testing different methods can yield surprising results.

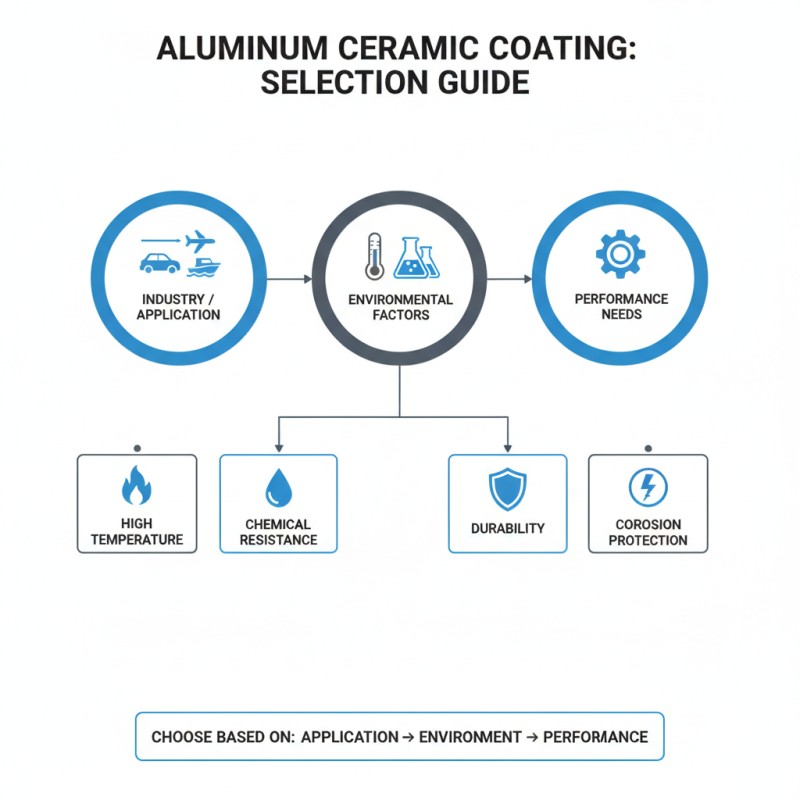

Choosing the right aluminium ceramic coating depends on various factors. Consider the specific application needs first. Different industries have unique demands. For instance, automotive, aerospace, and marine sectors require tailored solutions. Each environment presents its challenges. Some coatings excel in high temperatures, while others resist chemical exposure better.

Evaluate the surface type and its conditions. Will it face high friction or extreme weather? This affects coating selection significantly. A durable finish might not be necessary for indoor applications. Sometimes, basic protection will suffice. Testing different coatings can reveal unexpected results. Documenting these findings helps refine choices in the future.

Cost is also a crucial factor. High-performance coatings may require a larger investment upfront. However, they can save money over time through reduced maintenance. Weigh the long-term benefits against initial costs. It is essential to strike a balance. If the decision feels overwhelming, consulting with experts can provide clarity. Keep in mind that innovation in materials is ongoing, and staying informed is vital.