In the rapidly evolving landscape of advanced materials, Zirconia Rods have emerged as a cornerstone of innovation, significantly impacting various industrial sectors. According to a market analysis report by Global Industry Analysts, the global zirconia market is projected to reach approximately $2.5 billion by 2025, with Zirconia Rods accounting for a substantial share due to their exceptional mechanical properties and thermal stability. As industries increasingly prioritize performance and sustainability, the demand for Zirconia Rods in applications ranging from aerospace to medical devices is set to soar. China, with its robust manufacturing capabilities and commitment to quality, is poised to redefine global standards in this arena. This blog will explore the current market dynamics, highlighting key data points and providing insightful tips for stakeholders looking to navigate this burgeoning market in 2025 and beyond.

In the rapidly evolving landscape of advanced materials, Zirconia Rods have emerged as a cornerstone of innovation, significantly impacting various industrial sectors. According to a market analysis report by Global Industry Analysts, the global zirconia market is projected to reach approximately $2.5 billion by 2025, with Zirconia Rods accounting for a substantial share due to their exceptional mechanical properties and thermal stability. As industries increasingly prioritize performance and sustainability, the demand for Zirconia Rods in applications ranging from aerospace to medical devices is set to soar. China, with its robust manufacturing capabilities and commitment to quality, is poised to redefine global standards in this arena. This blog will explore the current market dynamics, highlighting key data points and providing insightful tips for stakeholders looking to navigate this burgeoning market in 2025 and beyond.

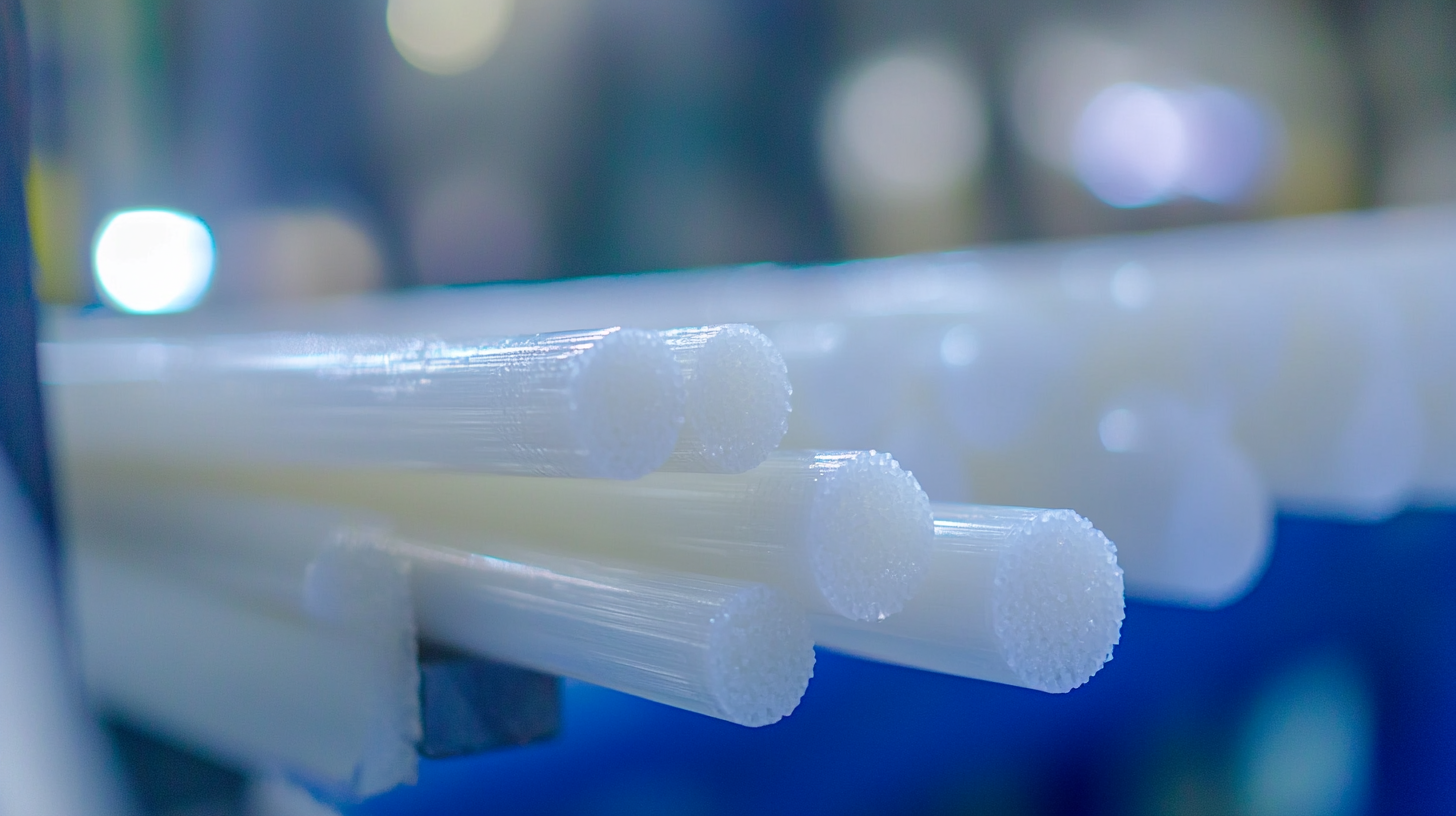

The emergence of zirconia rods marks a significant innovation in material science, positioning China at the forefront of global manufacturing excellence. Zirconia, known for its exceptional hardness and resistance to wear, has transformed industries ranging from dental applications to advanced engineering. Chinese manufacturers have harnessed cutting-edge technology and research to produce these rods, ensuring they meet international standards while also setting new benchmarks for quality and durability.

China's commitment to innovation has led to the development of zirconia rods that not only rival but often surpass those manufactured elsewhere. This leap in technology is attributed to a blend of traditional craftsmanship and modern engineering techniques, resulting in products that are not only efficient but also environmentally sustainable. The integration of advanced sintering processes and precision engineering has allowed for greater customization, making these zirconia rods suitable for various specialized applications across multiple sectors on a global scale.

| Innovation Aspect | Description | Impact | Global Standard |

|---|---|---|---|

| Material Composition | High purity zirconia to enhance durability and performance | Reduces wear and tear in industrial applications | Meets ISO 13485 for medical applications |

| Manufacturing Process | Advanced sintering techniques for precision | Increases efficiency in production lines | Aligns with ASTM standards for manufacturing |

| Applications | Used in dental, industrial, and electronic sectors | Enhances performance across diverse applications | Recognized by international quality certifications |

| Sustainability Practices | Environmentally friendly production techniques | Minimizes carbon footprint | Meets global sustainability goals |

The production of zirconia has witnessed a revolutionary shift, particularly with China's burgeoning role as a leader in setting quality standards. According to a recent report by the Global Zirconia Market Analysis, the country accounted for approximately 45% of the world's zirconia output in 2022. This statistic underscores not only China's significant capacity but also its commitment to enhancing production quality, establishing benchmarks that resonate across the global industry.

One prominent aspect of China's excellence in zirconia production is its adherence to rigorous quality control measures. Research from the Zirconia Producers Association reveals that Chinese manufacturers are increasingly employing advanced technologies, such as high-temperature sintering and precision milling, to achieve superior material properties. Enhanced mechanical strength and resistance to wear and corrosion are critical factors that have positioned Chinese zirconia products as favorites in sectors ranging from medical devices to electronics, with global demand projected to grow at a CAGR of over 6% through 2027. As such, China is not only meeting but exceeding traditional benchmarks, thereby reshaping the industry's quality landscape.

The global impact of Chinese zirconia rods is sweeping across multiple industries, showcasing the remarkable innovations and quality standards that China has integrated into manufacturing. Industries such as dentistry, aerospace, and electronics are increasingly utilizing zirconia rods due to their superior properties, including high strength, wear resistance, and exceptional biocompatibility. As a result, Chinese brands have carved out a significant market presence, becoming key players in meeting the growing demand for reliable and effective materials worldwide.

One notable aspect of the Chinese zirconia rods is their adeptness at enhancing the performance of components in high-stress environments. In the dental sector, for instance, these rods are utilized to produce durable dental crowns and bridges, prolonging patient satisfaction and reducing the frequency of replacements. Meanwhile, in aerospace applications, their lightweight yet robust nature aids in manufacturing parts that withstand extreme conditions without compromising safety. As industries continue to recognize the benefits of Chinese zirconia rods, their proliferation marks a pivotal shift in global standards, driving innovation and competition on an international scale.

The manufacturing of zirconia rods is undergoing a transformative shift, particularly in China, where sustainable practices are becoming paramount. Recent studies indicate that zirconia production contributes significantly to a circular economy, with a reported reduction of over 30% in carbon emissions when adopting eco-friendly processes. This commitment to sustainability is driven by rigorous industry standards and advancements in technology, underscoring a broader movement towards responsible manufacturing.

Additionally, the Chinese zirconia industry is innovating in raw material sourcing, emphasizing the importance of recycled and locally sourced materials. Reports from the International Journal of Advanced Manufacturing Technology reveal that by utilizing recycled zirconia, manufacturers can decrease resource depletion by up to 40%. This not only aligns with global sustainability goals but also reinforces the quality and durability that zirconia products are known for, making them increasingly appealing in various applications, from dental prosthetics to advanced ceramic components. The integration of these sustainable practices highlights the evolving landscape of zirconia manufacturing, bringing together quality, efficiency, and environmental responsibility.

Zirconia rods are emerging as a crucial element in advancing material science, particularly due to their

exceptional properties. Recent industry reports indicate that the global market for zirconia ceramics is

anticipated to reach $5 billion by 2026, driven largely by

their high fracture toughness and resistance to wear and corrosion. As researchers and manufacturers

alike explore innovative applications, zirconia rods are poised to redefine standards in various fields,

including dental prosthetics, aerospace, and electronics.

Zirconia rods are emerging as a crucial element in advancing material science, particularly due to their

exceptional properties. Recent industry reports indicate that the global market for zirconia ceramics is

anticipated to reach $5 billion by 2026, driven largely by

their high fracture toughness and resistance to wear and corrosion. As researchers and manufacturers

alike explore innovative applications, zirconia rods are poised to redefine standards in various fields,

including dental prosthetics, aerospace, and electronics.

One important trend is the increasing focus on the eco-friendliness of materials. Zirconia is often favored for its sustainability characteristics, making it an attractive option for industries looking to reduce their carbon footprint. According to a recent study, eco-friendly materials account for over 25% of the new product development initiatives in the ceramics industry, highlighting a shift towards sustainable practices.

Tip: When selecting zirconia rods for your applications, consider their specific properties, such as thermal expansion and electrical insulation. These factors will significantly influence performance based on your project needs.

As advancements in manufacturing technology unfold, the versatility of zirconia rods will only grow. Enhanced processing techniques are enabling the production of zirconia with tailored properties, making them highly applicable in cutting-edge sectors.

Tip: Stay updated with industry advancements by following publications and attending conferences focused on material science, as this will keep you informed about emerging trends and innovations involving zirconia materials.