In the realm of high-performance applications, the choice of materials can significantly impact the overall efficiency and durability of a product. Zirconia rods, known for their exceptional mechanical properties and resilience, have emerged as a leading choice in various industries, including aerospace, automotive, and medical devices.

According to a recent market analysis by Research and Markets, the demand for advanced ceramic materials, including zirconia-based products, is projected to grow at a CAGR of 6.8% through 2025, driven by the increasing need for lightweight, corrosion-resistant solutions that can withstand extreme conditions.

Zirconia rods have emerged as the preferred material for high-performance applications due to their exceptional properties. One of the key features of zirconia is its high fracture toughness, with values reaching up to 10 MPa·m^1/2, which significantly surpasses traditional ceramics. This toughness allows zirconia rods to withstand extreme stress and impact, making them ideal for use in industries such as aerospace, automotive, and biomedical applications. According to a report by the International Journal of Advanced Manufacturing Technology, the use of zirconia components can enhance reliability and longevity in demanding environments, which can reduce overall operational costs.

Moreover, zirconia exhibits excellent thermal resistance, maintaining stability at temperatures as high as 1400°C. This characteristic is critical in applications involving high heat exposure. In the semiconductor manufacturing sector, for example, zirconia rods are often employed in processes that require precision under high-temperature conditions. A study published in Materials Science and Engineering concluded that the thermal conductivity of zirconia is relatively low, which helps in minimizing heat transfer and protecting sensitive components during manufacturing processes. These unique properties not only enhance performance but also open new horizons for innovation in material engineering, reinforcing zirconia rods as the optimal choice for high-performance applications.

Zirconia rods are increasingly recognized as a superior choice for high-performance applications, particularly in high-temperature environments. Their exceptional thermal stability and resistance to corrosion make them ideal candidates for use in nuclear fuel cladding and other critical components subjected to extreme conditions. Recent studies have shown that zirconium alloys, when properly treated, can enhance durability and longevity in high-stress scenarios, such as those found in pressurized water reactors. Reports indicate that the use of zirconia can significantly reduce degradation phenomena, such as "shadow corrosion," which affects the lifespan of traditional zirconium alloy fuel rods.

In the realm of advanced nuclear technologies, zirconia rods are indispensable due to their ability to withstand abrasive environments. The development of innovative ceramic fuel cladding materials has further improved the performance of zirconia in high-temperature applications. For example, research highlights that ultra-high temperature ceramics incorporating zirconium demonstrate remarkable resilience, achieving thermal stability even beyond 2000°C. This positions zirconia rods not only as essential components in next-generation nuclear reactors but also as crucial materials for enhancing the efficiency and safety of energy systems transitioning to sustainable solutions.

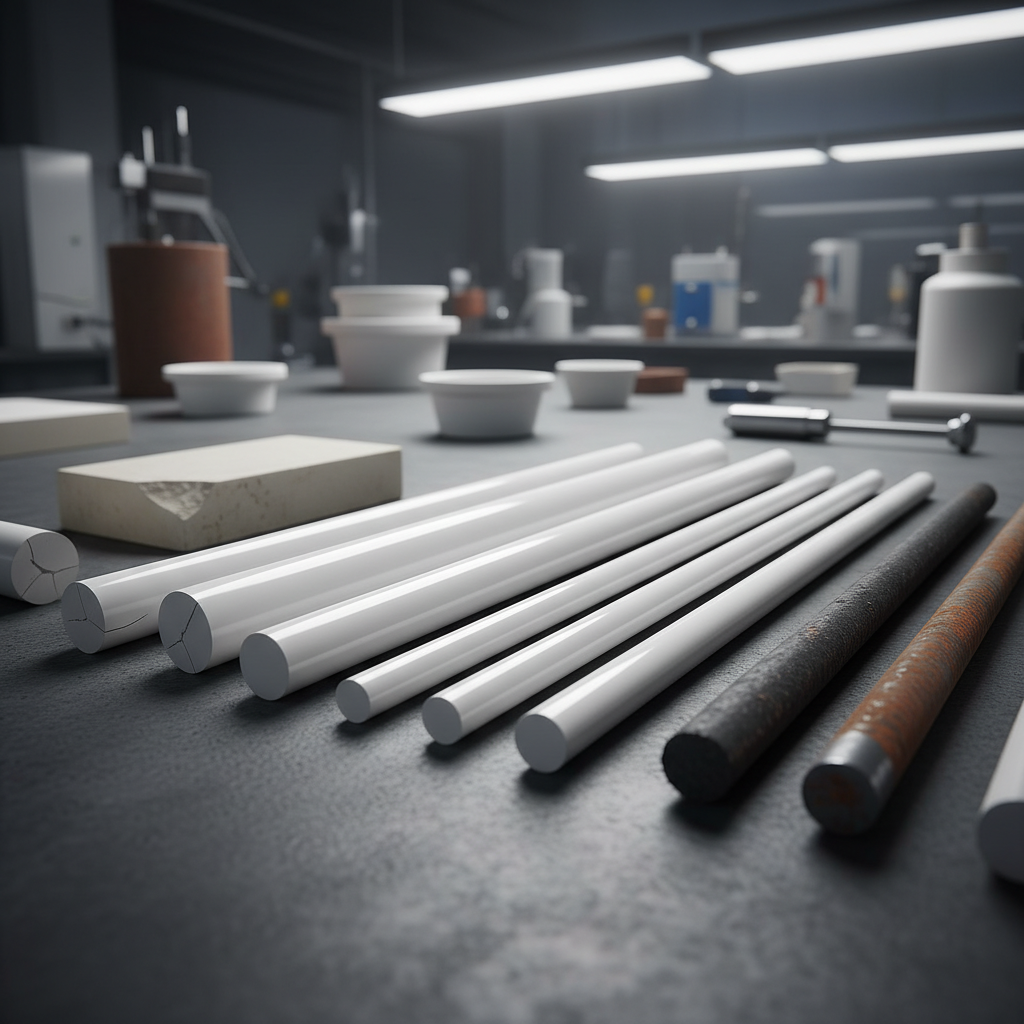

Zirconia rods have emerged as a superior option for high-performance applications, particularly when compared to materials like aluminum oxide, silicon carbide, and metal rods. A report by Research and Markets indicates that zirconia's toughness and wear resistance outperform aluminum oxide by nearly 50%, making it the preferred choice for industries such as aerospace and medical devices. The intrinsic properties of zirconia, including its ability to withstand extreme temperatures and corrosive environments, provide significant advantages over alternatives, which often falter under similar conditions.

Tips: When selecting materials for high-performance applications, consider the specific mechanical properties required. For instance, zirconia rods typically exhibit a flexural strength of about 1,200 MPa, compared to only 300 MPa for standard aluminum oxide. This difference can be crucial in applications involving high stress or load.

Furthermore, when evaluating cost versus performance, keep in mind that while zirconia rods may have a higher initial investment, their longevity and reduced replacement frequency can lead to lower overall costs in the long run. According to a study published in the Journal of Materials Science, using zirconia can enhance service life by more than two times compared to traditional materials, offering substantial savings and performance consistency in demanding environments.

Zirconia rods have emerged as a preferred material in various high-performance applications, largely due to their exceptional cost-effectiveness and impressive longevity. The manufacturing process of zirconia rods often involves advanced techniques that reduce waste and optimize material usage, making them an economically viable option for industries ranging from aerospace to medical equipment. Unlike traditional materials, zirconia rods offer superior resistance to wear and corrosion, resulting in lower maintenance costs over time. This characteristic not only enhances their appeal but also translates into significant savings for companies looking to maintain productivity without incurring excessive replacement costs.

In addition to their cost benefits, the longevity of zirconia rods is a key factor that drives their popularity. With the ability to withstand extreme temperatures and mechanical stress, these rods maintain structural integrity far longer than their metal or polymer counterparts. This durability is particularly advantageous in applications demanding consistent performance over extended periods. By investing in zirconia rods, industries ensure that operational efficiency is maintained while minimizing downtime related to equipment failures. Overall, the unique combination of affordability and long service life makes zirconia rods an ideal choice for businesses seeking high-performance solutions without compromising on budget or reliability.

| Property | Zirconia Rods | Alumina Rods | Steel Rods |

|---|---|---|---|

| Density (g/cm³) | 6.05 | 3.90 | 7.85 |

| Flexural Strength (MPa) | 1200 | 300 | 400 |

| Thermal Conductivity (W/m·K) | 2.5 | 40 | 45 |

| Hardness (Mohs) | 8.5 | 8.0 | 4.0 |

| Cost per kg (USD) | 25 | 10 | 5 |

The future of zirconia rod technology is poised for significant advancements, driven by an increasing demand for high-performance materials across various industries. According to a recent report by MarketsandMarkets, the global zirconia market is expected to grow from $1.2 billion in 2020 to $1.9 billion by 2025, with applications spanning from aerospace to biomedical fields. This surge is attributed to zirconia's exceptional properties, including high fracture toughness, chemical resistance, and biocompatibility, making it an ideal choice for advanced applications.

Emerging trends in zirconia rod technology include the development of hybrid materials and innovative processing techniques aimed at enhancing performance characteristics. Research indicates that the introduction of nanomaterials can significantly improve the mechanical strength and wear resistance of zirconia rods, leading to longer service life and reduced maintenance costs. Furthermore, advancements in additive manufacturing are enabling the customization of zirconia components, allowing for tailored solutions in specialized sectors such as dental prosthetics and precision engineering. The confluence of these trends is expected to redefine what is achievable with zirconia rods, making them indispensable in the future of high-performance applications.