The evolution of modern electronics has been significantly influenced by the integration of advanced materials, with ceramic semiconductors emerging as pivotal components in various applications. According to a recent report by MarketsandMarkets, the global market for ceramic semiconductors is projected to reach $XX billion by 2026, reflecting a robust compound annual growth rate (CAGR) of XX%. This growth is driven by their unique properties, such as high thermal stability, excellent dielectric performance, and resistance to corrosion, making them ideal for use in high-frequency and high-power devices. As industries increasingly demand efficient and reliable components, ceramic semiconductors have gained traction, particularly in sectors like telecommunications, automotive, and consumer electronics. Understanding the role of ceramic semiconductors is crucial for leveraging their advantages to meet the challenges of next-generation electronic devices.

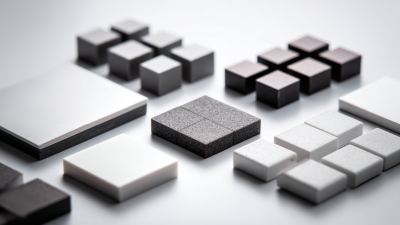

Ceramic semiconductors are a vital component in modern electronics, characterized by their exceptional thermal stability and electrical insulating properties. Comprised primarily of metal oxides, they exhibit unique electronic behaviors that make them suitable for high-temperature applications where traditional semiconductors might fail. One of the key properties of ceramic semiconductors is their wide bandgap, which allows them to operate effectively in harsh environments. This quality enables devices to function in circumstances with extreme temperatures and potentially corrosive conditions, making them ideal for aerospace and automotive applications.

Additionally, ceramic semiconductors demonstrate remarkable dielectric strength, which contributes to their reliability in electronic circuits. Their ability to maintain performance under varying electrical fields makes them increasingly important in capacitive devices and insulators. Moreover, advancements in material science have led to the development of hybrid ceramic-semiconductor materials, combining the robustness of ceramics with the functional capabilities of semiconductors. This innovation not only enhances performance but also opens up new avenues for miniaturization in electronic design, enabling the creation of smaller, more efficient devices.

This chart illustrates the dielectric constant and breakdown voltage of various ceramic materials used in semiconductor applications. The properties of ceramic semiconductors are vital for the development of high-efficiency electronic components.

Ceramic semiconductors have gained prominence in modern electronics due to their unique properties that enhance performance and longevity. The global ceramic substrate market is projected to reach approximately USD 13.50 billion by 2032, growing at a compound annual growth rate (CAGR) of 6.42% during the forecast period. This growth underscores the increasing reliance on ceramics in semiconductor applications, driven by their excellent thermal stability and electrical insulation properties. As electronics demand continues to expand, ceramic materials are emerging as a critical component in achieving higher efficiency and reliability.

One significant advantage of ceramic semiconductors lies in their compatibility with advanced chip packaging technologies. The evolution of semiconductor packaging is crucial for enhancing performance and reducing footprint, and ceramics provide a robust alternative to traditional materials. By integrating ceramic substrates, manufacturers can facilitate better heat dissipation and improved signal integrity, which are essential in high-performance electronic devices. The burgeoning semiconductor ceramic consumable parts market, valued at approximately USD 6.1 billion in 2024, indicates a strong inclination towards utilizing ceramics in achieving superior electrical performance and durability in modern electronic components.

Ceramic semiconductors have gained significant traction in the realm of modern electronics due to their unique properties, making them ideal for various applications. One notable application is in the manufacturing of capacitors and insulators used in high-frequency devices. The high dielectric constant of certain ceramic materials allows for miniaturization of components, enabling the production of smaller, more efficient electronic devices without compromising performance. This is particularly advantageous in smartphones and wearable technologies that require compact designs without sacrificing functionality.

Additionally, ceramic semiconductors are increasingly used in sensors, including temperature and pressure sensors, which are integral to the Internet of Things (IoT). Their excellent thermal stability and reliability make them suitable for harsh environments, ensuring accurate readings over prolonged periods. Moreover, advancements in ceramic materials have led to the development of piezoelectric ceramics, which convert mechanical stress into electrical energy, thus powering various small devices sustainably. This versatility underscores the growing importance of ceramic semiconductors in enhancing the functionality and durability of modern electronic devices.

The application of ceramic semiconductors in modern electronics presents a unique set of challenges and limitations that warrant closer examination. One of the primary issues surrounding ceramic semiconductors is their susceptibility to harsh environments, such as extreme temperatures and radiation, particularly in aerospace applications. These conditions can lead to accelerated aging and potential failure of semiconductor components, requiring robust solutions to ensure reliability and longevity. Addressing these environmental challenges is vital for the successful deployment of ceramic semiconductors in critical applications.

Moreover, the manufacturing and production processes for ceramic semiconductors introduce additional hurdles. The techniques involved in producing ceramics, including additive manufacturing and optimization for specific electronic properties, can be complex and resource-intensive. Recent advancements in high-entropy materials show promise in enhancing the tunability of ceramic properties; however, scalability and cost-effectiveness remain significant concerns. As the semiconductor industry rapidly evolves, the development of sustainable practices and innovative materials will be essential for overcoming these limitations and maximizing the potential of ceramic semiconductors in next-generation electronic devices.

| Dimension | Details |

|---|---|

| Material Composition | Alumina, Silicon Carbide, Titanates |

| Common Applications | Capacitors, Resistors, Piezoelectric Devices |

| Advantages | High Thermal Stability, Excellent Dielectric Properties |

| Challenges | Brittleness, Limited Processability, High Cost |

| Performance Limitations | Low Electron Mobility, Sensitivity to Temperature Variations |

| Future Trends | Hybrid Materials, Improved Fabrication Techniques |

The ceramic semiconductor market is poised for significant growth as technological advancements continue to shape the landscape of modern electronics. According to industry reports, the vacuum automatic heat treatment furnace market is projected to reach a value of $594.29 million in 2024 and is expected to grow to approximately $664.13 million by 2032, reflecting a modest annual growth rate of 1.4%. This indicates a robust demand not only for the furnaces themselves but also for the ceramic materials that enable their efficiency and performance.

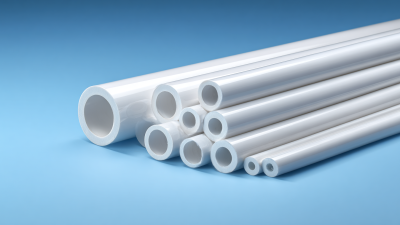

Analyzing specific segments, the ceramic substrate market is anticipated to expand significantly, driven by growing applications across various sectors including consumer electronics, aerospace, automotive, and semiconductors. The market is subdivided by product types such as aluminum oxide, aluminum nitride, silicon nitride, and beryllium oxide, alongside forms like boards, sheets, and films. This segmentation highlights the diverse range of applications and material requirements in the industry. As the demand for high-performance and environmentally friendly materials increases, the ceramic semiconductor technology is likely to evolve, enabling innovations that support the future of electronics.