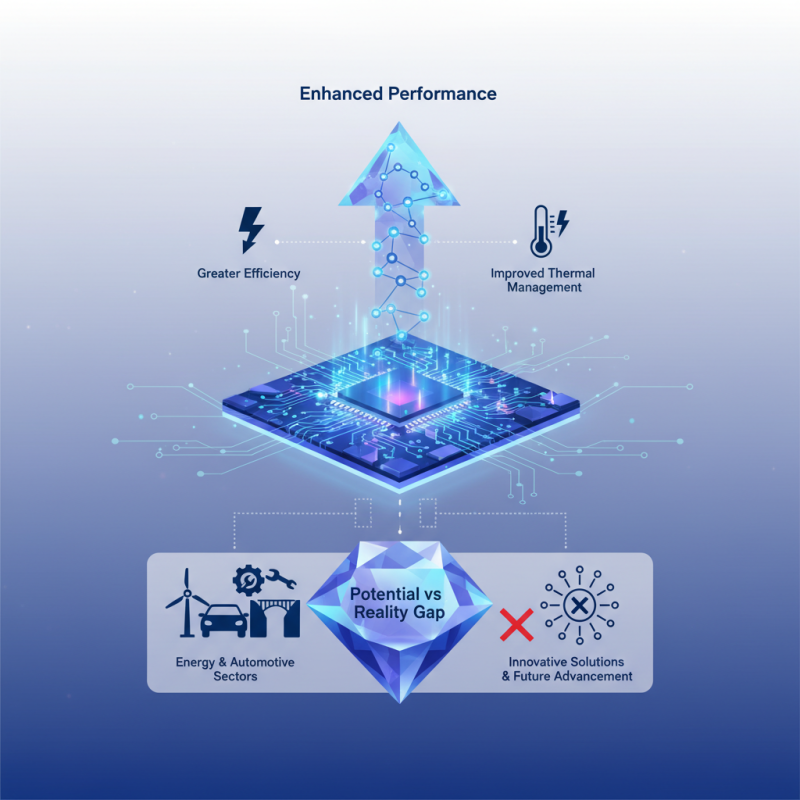

Silicon Carbide Electronics represents a significant evolution in the field of semiconductor technology. This innovative material allows for greater efficiency and improved thermal management. Industries are increasingly adopting Silicon Carbide due to its unique properties. Its ability to operate at high temperatures and voltages makes it suitable for demanding applications.

As we explore this transformative technology, we must consider how it impacts various sectors, including energy and automotive. The adoption of Silicon Carbide can lead to significant increases in performance. However, challenges remain in terms of manufacturing and integration. Companies face hurdles when transitioning from traditional materials to Silicon Carbide.

Reflection on these challenges can foster more innovative solutions. The gap between potential and reality in Silicon Carbide deployment is still present. By addressing these issues, we can fully leverage the promising capabilities of Silicon Carbide Electronics. Embracing this technology offers both opportunities and obstacles, paving the way for future advancements.

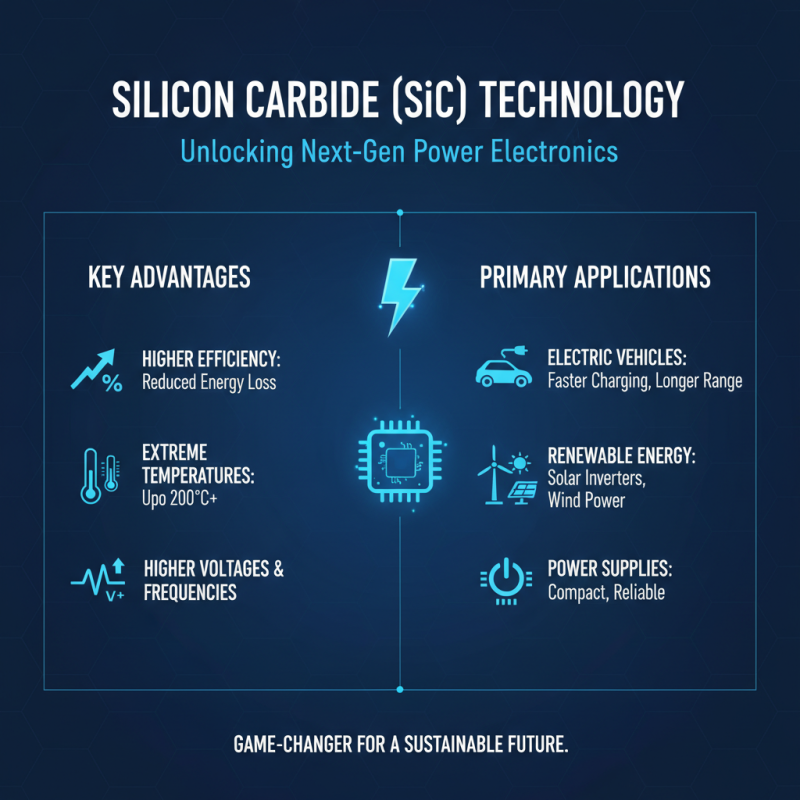

Silicon carbide (SiC) technology has been a game changer in many industries. Its unique properties allow for higher efficiency and greater performance compared to traditional silicon. SiC devices can operate at higher voltages, temperatures, and frequencies. This makes them ideal for power electronics in electric vehicles and renewable energy systems.

Using SiC can lead to significant advantages. For instance, they reduce energy loss and improve thermal management. In comparison, conventional materials often struggle under similar conditions. However, integrating SiC into existing systems can sometimes be challenging. Engineers must consider compatibility with legacy technologies. Moreover, optimizing designs can require skilled expertise, which can be a barrier.

The benefits are clear, yet it’s not a flawless solution. The cost of SiC components remains higher than their silicon counterparts. This raises questions about the initial investment versus long-term savings. In some cases, users may not see immediate returns. Exploring these nuances is essential for anyone looking to leverage SiC effectively.

Silicon carbide (SiC) electronics have a significant impact across various industries. These materials exhibit high thermal conductivity and high breakdown voltage. A report from the Energy Institute indicates that SiC devices can operate at temperatures up to 200°C. This capability enhances performance in sectors like automotive, energy, and aerospace.

In the automotive industry, SiC components improve efficiency in electric vehicles (EVs). They enable faster charging and longer ranges, which is crucial for consumer adoption. Recent data suggests EVs with SiC power electronics can achieve a 10-15% increase in efficiency compared to traditional silicon devices. However, the integration process is complex and may require skilled labor to optimize.

The renewable energy sector also benefits. SiC-based inverters can boost the efficiency of solar panels. According to a study by the International Renewable Energy Agency, SiC technology can improve solar inverter efficiency by almost 2%. Still, manufacturers face challenges in scaling production. The transition from silicon to SiC isn't seamless and demands significant investment. This highlights the need for industry-wide reflection on capabilities and resources.

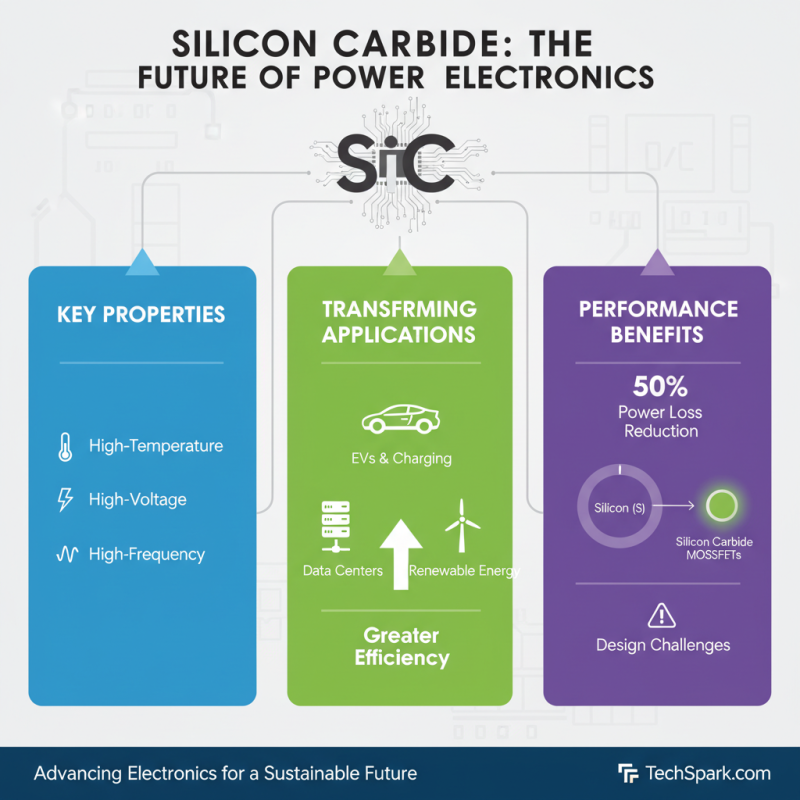

Silicon carbide (SiC) is transforming the electronics landscape. Its properties enable better performance in high-temperature, high-voltage, and high-frequency applications. As industries push for greater efficiency, SiC-based systems are gaining traction. Data shows that SiC MOSFETs can reduce power loss by 50% compared to silicon counterparts. However, harnessing SiC technology comes with design challenges.

Thermal management stands out as a key consideration. SiC devices operate at higher temperatures, necessitating efficient cooling solutions. Inadequate thermal management can lead to system failure. A well-designed thermal interface can ensure reliable operations, mitigating risks. Additionally, circuit layout plays a vital role in overall performance. Designers must minimize electromagnetic interference (EMI) to maintain signal integrity. Even minor layout errors can affect performance significantly.

Integration of SiC components requires a thorough understanding of packaging techniques. Poor packaging can lead to issues, such as reduced reliability and increased costs. Understanding the physical properties of SiC is crucial. Designers must be aware that not all conventional techniques apply. Investing time in research and development can lead to improved designs and better outcomes. This exploration is vital as SiC technology continues to evolve.

Silicon carbide (SiC) devices are revolutionizing electronic performance. Their efficiency metrics are crucial for evaluation. Key parameters include conduction loss, switching speed, and thermal management. SiC technologies allow for higher voltage and temperature operation. This leads to improved power conversion and reduced energy waste.

However, challenges remain. The real-world performance of SiC devices can vary. Not all applications may benefit equally from their capabilities. Performance may degrade under extreme conditions. Proper thermal management becomes critical yet underestimated in many designs. Understanding these nuances is vital for optimizing SiC usage.

Users must consider both advantages and limitations. Enhanced efficiency can lead to longer lifespans for devices. But, careful design and implementation are necessary. The potential to harness SiC technology is significant, yet it requires thorough evaluation and testing. Always keep questioning how to achieve the best results.

Silicon carbide (SiC) electronics are paving the way for new innovations across various industries. These devices excel in high-temperature and high-voltage applications. As demand for efficient power conversion grows, SiC technology is vital. Many are exploring its potential in electric vehicles and renewable energy systems.

The future trends in SiC electronics will focus on enhanced efficiencies and miniaturization. Researchers are working on improving chip designs. This growth may lead to smaller, more effective power modules. Companies are also investigating new manufacturing techniques. These advancements could reduce costs and increase accessibility. However, challenges remain, including the need for improved thermal management.

Despite its promise, there is room for reflection. The market is still maturing, and widespread adoption will take time. Some engineers are still adjusting to SiC's unique properties. Additionally, education around SiC technology is crucial for its growth. Emphasizing sustainable practices will ensure a brighter future for silicon carbide applications.