Aluminium Oxynitride, often abbreviated as ALON, is rapidly establishing itself as a revolutionary material in the field of optical technologies. With the optical components market projected to reach $28 billion by 2025, driven by advancements in defense, telecommunications, and consumer electronics, the demand for high-performance materials with superior optical and mechanical properties is at an all-time high. ALON combines the beneficial characteristics of both ceramics and glasses, offering exceptional hardness, excellent transmission in the visible to infrared spectrum, and remarkable resistance to harsh environments. According to a recent report by Mordor Intelligence, the global market for advanced materials, including Aluminium Oxynitride, is expected to grow at a CAGR of 12% through 2026. This impressive growth underscores the increasing interest and investment in ALON as a potential game changer for next-generation optical devices, paving the way for innovations in fields such as secure communications, enhanced imaging systems, and durable optical components.

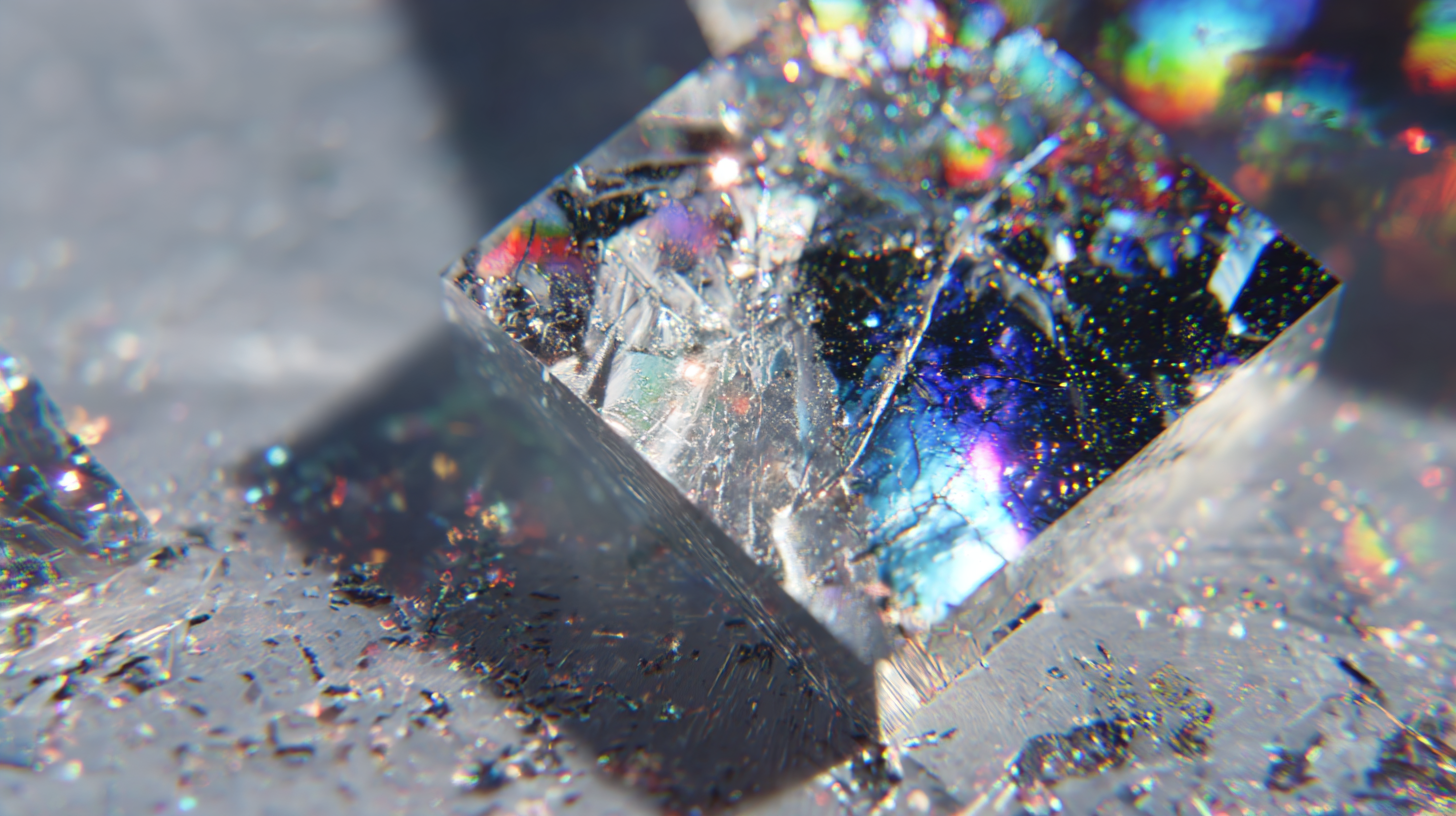

Aluminium oxynitride (ALON) is rapidly emerging as a game changer in the field of optical technologies, primarily due to its unique properties. This ceramic material exhibits exceptional hardness and high thermal stability, making it ideal for applications where durability is crucial, such as in military and aerospace optoelectronics. Additionally, ALON offers significant transparency across a wide range of wavelengths, from visible to infrared, enabling its use in advanced optical systems and sensors.

One of the standout features of aluminium oxynitride is its ability to combine high strength with low weight, a characteristic that is particularly beneficial in handling high-impact scenarios. Furthermore, its resistance to chemical corrosion and environmental degradation enhances its longevity and reliability in various settings. These attributes not only improve performance in optical applications but also open up new possibilities for innovations in security, telecommunications, and even consumer electronics.

As research and development continue, aluminium oxynitride is poised to redefine standards in optical materials, providing both functionality and resilience in future technologies.

Aluminium oxynitride (ALON) is rapidly emerging as a transformative material in the realm of advanced imaging technologies. Known for its superior hardness, transparency across a broad spectrum of wavelengths, and exceptional thermal stability, ALON is poised to revolutionize applications in fields ranging from military optics to consumer electronics. According to a report from MarketsandMarkets, the global market for advanced imaging technologies is projected to reach $35 billion by 2025, with ALON playing a central role in military-grade cameras, high-performance lenses, and optical sensors.

One notable application of ALON is in the development of cutting-edge sensors that can operate under extreme conditions while maintaining high performance. The U.S. Army has begun integrating ALON-based optics in surveillance systems, enhancing the capabilities of long-range imaging equipment. Moreover, the high scratch resistance of ALON makes it ideal for use in environments where durability is paramount, such as in drones and robotic systems. As this material becomes more readily available and manufacturing processes scale, its influence on the imaging technology landscape is expected to grow, paving the way for innovations that were previously unimaginable.

Aluminium oxynitride (ALON) is gaining traction in optical technologies, primarily due to its unique properties that propose significant advantages over traditional optical materials like glass and plastics. According to a report by the Global Optical Materials Market, ALON exhibits superior hardness (Mohs hardness of 8.5) and excellent thermal stability, making it particularly suitable for applications in harsh environments. This translates to improved durability and longevity for optical components, which is a critical factor in aerospace and defense industries, where performance and reliability are paramount.

When comparing ALON to traditional optical materials, one of the defining metrics is transmission efficiency. ALON has a wide transparency range, from ultraviolet through to the infrared spectrum, with a transmission rate exceeding 70% in the visible light range. Traditional materials such as glass typically exhibit lower transmission rates (around 90% in optimal conditions), but they are less effective for a broader spectrum of light. Furthermore, ALON’s resistance to yellowing over time presents a substantial advantage over conventional polymers, which tend to degrade under UV exposure. This makes ALON an ideal candidate for next-generation optical systems, providing both improved performance and extended service life.

This chart compares the optical properties of Aluminium Oxynitride (AlON) with traditional optical materials such as glass and quartz. The data reflects average values in terms of transmittance and durability, showcasing the potential advantages of AlON.

Aluminium oxynitride (ALON) is emerging as a revolutionary material in the realm of optical technologies, promising enhanced performance in various applications ranging from transparent armor to advanced sensors. However, the manufacturing processes of ALON components face significant hurdles. The inherent properties of ALON, such as its high hardness and thermal stability, necessitate specialized production techniques. According to recent industry reports, conventional ceramic methods often fail to meet the stringent requirements for uniformity and scalability, critical for commercial success.

To tackle these manufacturing challenges, innovative approaches are being explored. One promising solution involves leveraging advancements similar to those seen in the production of sialon ceramics, which have demonstrated excellent machinability and thermal shock resistance. Initiatives aimed at optimizing sintering processes and using additive manufacturing techniques could pave the way for more efficient and cost-effective production of ALON components. A report from a leading materials science journal noted that the integration of these methods could potentially increase yield rates by up to 30%, thereby enhancing the viability of ALON in high-demand optical applications. The ongoing research and development efforts in this field highlight the importance of overcoming manufacturing challenges to unlock the full potential of aluminium oxynitride technologies.

| Dimension | Description | Value |

|---|---|---|

| Transmittance | Percentage of light passing through Aluminium Oxynitride | 85% |

| Hardness (Mohs) | Measured hardness on the Mohs scale | 9 |

| Thermal Conductivity | Ability to conduct heat, measured in W/m·K | 20 W/m·K |

| Manufacturing Cost | Estimated cost of producing Aluminium Oxynitride components | $500 per kg |

| Refractive Index | Optical property; ratio of speed of light in vacuum to that in material | 1.75 |

| Applications | Common uses in optical technology | Laser optics, transparent armor, UV optics |

| Challenge: Manufacturing Precision | Issue in achieving desired precision in component shape and size | High variability in properties |

| Solution: Advanced Techniques | Innovative methods to enhance manufacturing processes | 3D Printing, precision machining |

The future of aluminium oxynitride (AlON) is poised to revolutionize optical technologies, driven by ongoing innovations in research and development. With its unique properties, including high transparency across a wide range of wavelengths and exceptional hardness, AlON is becoming increasingly relevant in applications such as armor, aerospace, and telecommunications. As researchers continue to explore its potential, new manufacturing techniques could significantly lower production costs, enhancing its feasibility for broader commercial use.

In parallel, the global aluminium market is expanding significantly, projected to reach a value of USD 70.1 billion by 2034, growing at a CAGR of 4.5%. This growth reflects increasing demand for aluminium-based products across various sectors, including sustainable packaging solutions. Specifically, the German aluminium bottle market is expected to experience steady growth, driven by innovations in sustainability and packaging technology. By 2035, it is anticipated to rise to USD 623.6 million, underscoring Europe’s commitment to a sustainable packaging transition. Such advancements in aluminium-related technologies highlight a dynamic shift towards more innovative materials that align with global sustainability goals.