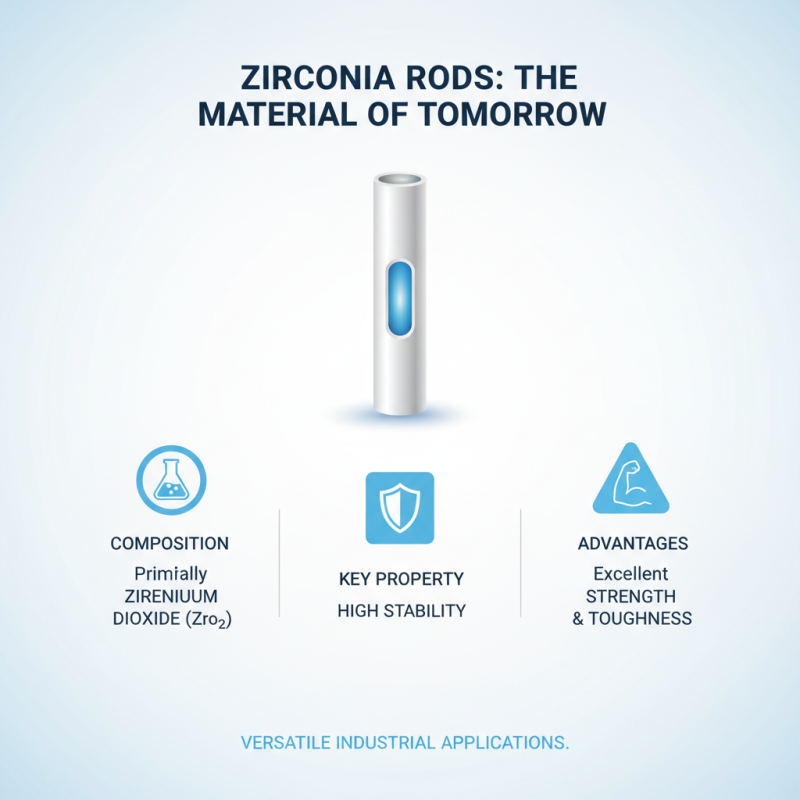

When considering materials for a project, Zirconia Rods stand out. These rods offer exceptional strength and durability. Their resistance to wear makes them ideal for demanding applications. Zirconia is also lightweight, making it easier to handle during assembly.

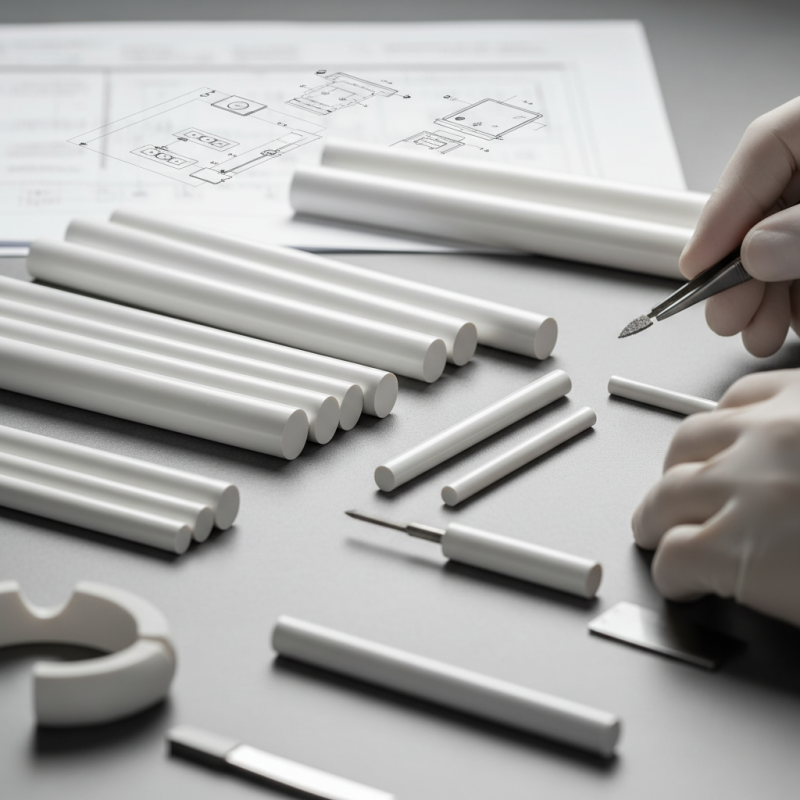

In industries like electronics and healthcare, Zirconia Rods prove valuable. They serve as insulators and components in medical devices. Their non-reactive nature ensures the safety of sensitive applications. However, working with these rods may require specific tools and techniques.

While Zirconia Rods are advantageous, challenges exist. They can be brittle, needing careful handling to avoid breakage. The investment in Zirconia can be higher than other materials. However, the benefits often outweigh these concerns, promising long-lasting performance. Exploring Zirconia Rods could be a game-changer for your next project.

Zirconia rods have gained popularity in various industries. Their unique composition primarily consists of zirconium dioxide (ZrO2). This chemical compound is well-known for its high stability. The material provides an excellent balance of strength and toughness. This makes it suitable for many demanding applications.

The mechanical properties of zirconia rods are impressive. They exhibit high fracture toughness, which is crucial for products exposed to stress. According to industry reports, the flexural strength of zirconia can reach up to 1200 MPa. This strength is significantly higher than many conventional materials. Additionally, zirconia is resistant to wear and corrosion. These characteristics enhance the longevity of components made from zirconia.

However, working with zirconia rods does come with challenges. The production process can be complex and costly. Fine processing is essential to achieve desired dimensions. Any imperfections during manufacturing can affect performance. It's crucial to assess the trade-offs involved. Investing in quality control measures may help mitigate potential issues.

Zirconia rods have gained popularity in various industries. Their remarkable properties make them ideal for both engineering and medical applications. One of the key advantages of zirconia rods is their high strength. Studies show they have a tensile strength of up to 1,200 MPa. This makes them six times stronger than standard ceramics.

In addition to strength, zirconia rods exhibit exceptional wear resistance. In abrasive environments, they outperform traditional materials. For example, in the dental sector, zirconia’s durability is crucial for long-lasting implants. According to recent data, 90% of dental practitioners prefer zirconia over other materials because of its longevity.

Moreover, zirconia rods are highly resistant to corrosion. They can withstand aggressive chemicals without degrading. This feature is vital in the chemical industry, where reactive substances are commonplace. However, it’s important to note that their production can be energy-intensive. Some manufacturers face challenges in scaling up without compromising quality. These factors highlight the need for continuous improvements in zirconia rod fabrication processes.

Zirconia rods are gaining popularity in various projects. When comparing zirconia rods to alternative materials, several factors come into play. Zirconia boasts high strength and toughness. It can withstand harsh environments commonly found in industrial applications.

In contrast, other materials might offer lower costs but are not as durable. For instance, plastic rods can fail under high heat. Metals, while strong, may corrode over time. This raises concerns about longevity. Additionally, zirconia’s resistance to wear ensures a longer service life.

However, zirconia is not without its drawbacks. The initial investment can be higher than alternatives. Some may question if the advantages justify the cost. Every project is unique. Evaluating the specific needs and challenges is essential. Careful consideration will help in making the right choice.

| Material | Strength (MPa) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Cost ($/kg) | Corrosion Resistance |

|---|---|---|---|---|---|

| Zirconia | 900 | 6.0 | 3.2 | 25 | Excellent |

| Alumina | 340 | 3.9 | 27 | 20 | Good |

| Silicon Carbide | 400 | 3.2 | 120 | 30 | Fair |

| Ceramic Composite | 600 | 4.5 | 10 | 22 | Good |

| Stainless Steel | 520 | 8.0 | 16 | 15 | Fair |

When selecting zirconia rods for your project, consider key factors. These rods come in various sizes and specifications. Understand your specific needs. This will guide your choice. The intended application can influence your selection significantly.

Tip: Research the specific material properties of zirconia. Durability and wear resistance are essential. Think about temperature resistance too. These factors affect how well the rods perform.

Another consideration is the manufacturing method. Different production processes can create variations in quality. Assess the tolerances your project requires. This can impact fit and functionality.

Tip: Always request samples before making a bulk purchase. Testing can prevent costly mistakes. Evaluate the rod’s performance in a real-world setting. It’s vital to ensure compatibility with your application.

Lastly, consult with experts if you're unsure. Gathering insights can save time and resources. Getting opinions helps clarify doubts. Prioritize informed decisions to enhance your project's success.

When considering zirconia rods for your next project, installation and maintenance are crucial. Proper installation ensures longevity and optimal performance. Make sure you understand the specifics of your project’s requirements. Each application can be unique, so tailor your approach accordingly. The environment where the rods will be used matters greatly.

Tips for installation include ensuring a clean surface. Dust and debris can impact adhesion. Use a level to maintain alignment. If you misalign, it could lead to premature wear. Additionally, avoid over-tightening. This can cause stress fractures.

Maintenance is another key aspect. Regular inspection can prevent issues. Look for signs of wear and tear, especially if used in harsh environments. Clean the rods using a soft cloth to avoid scratches. Chemicals can also affect the material; use mild solutions for cleaning. An ounce of prevention can save time and money in the long run. Remember, each project has its quirks. Reflect on your past experiences and learn from the challenges faced.