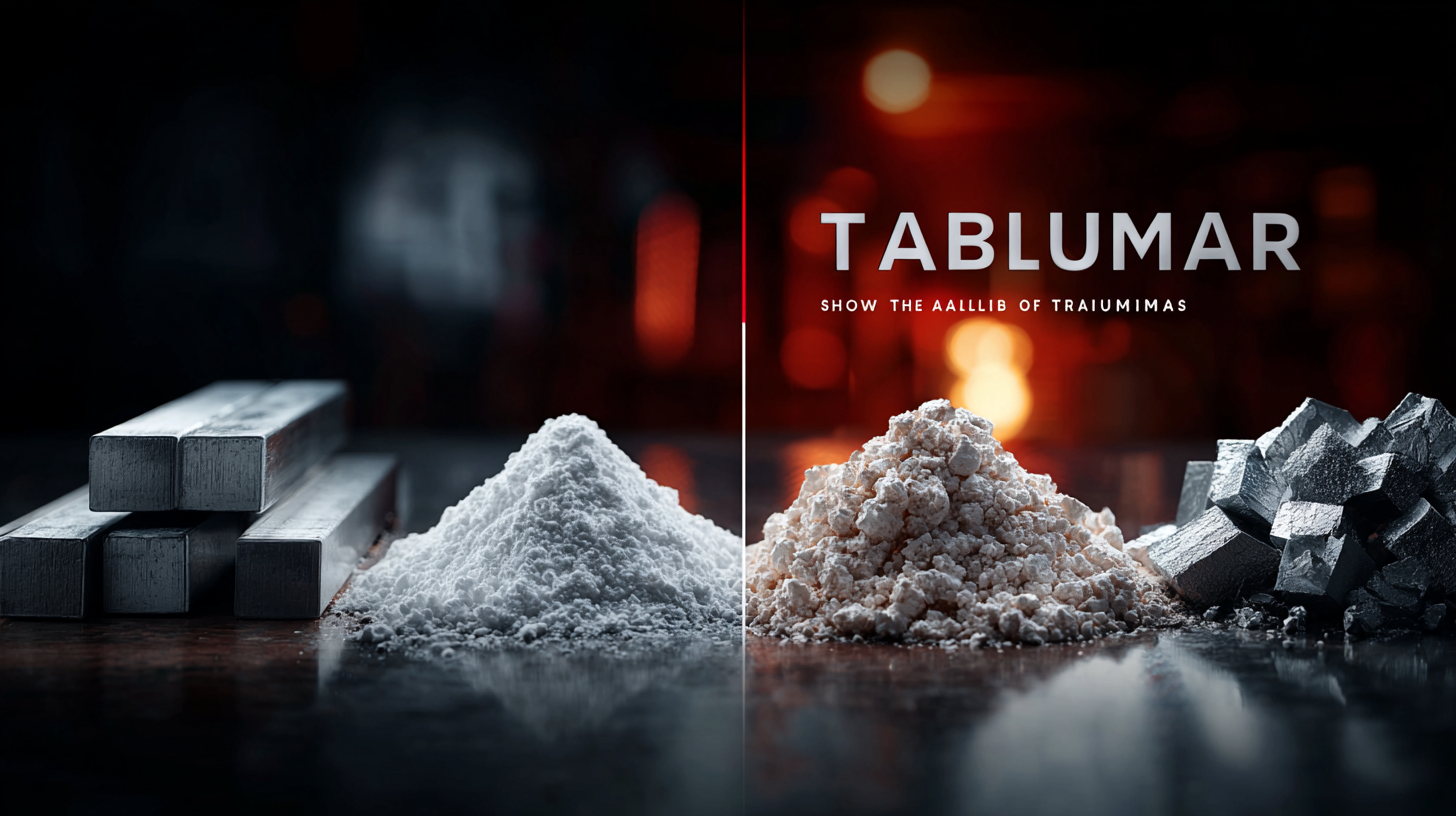

In the industrial landscape, selecting the right materials is crucial for optimizing performance and enhancing durability. Among various materials, Tabular Alumina stands out for its exceptional properties, such as high temperature resistance and low thermal conductivity, making it a preferred choice for applications in refractory, ceramic, and metal industries.

According to a recent market analysis, the global demand for alumina products is projected to grow at a CAGR of 4.5% from 2021 to 2026, highlighting the increasing reliance on high-quality alumina variants like Tabular Alumina. This specialized form of alumina is produced by sintering at high temperatures, resulting in a dense and pure product. Understanding the nuances of this material enables industries to make informed decisions tailored to their specific needs, thereby enhancing operational efficiency and overall product quality.

Tabular alumina is a highly valuable material in various industrial applications, known for its unique properties that enhance efficiency and performance. One of the key characteristics of tabular alumina is its high purity, typically exceeding 99.5%, which makes it an excellent choice for environments requiring minimal impurities. Additionally, its excellent thermal shock resistance and low thermal expansion coefficient allow it to withstand extreme temperatures and rapid temperature changes, making it ideal for use in kilns and furnaces.

Tabular alumina is a highly valuable material in various industrial applications, known for its unique properties that enhance efficiency and performance. One of the key characteristics of tabular alumina is its high purity, typically exceeding 99.5%, which makes it an excellent choice for environments requiring minimal impurities. Additionally, its excellent thermal shock resistance and low thermal expansion coefficient allow it to withstand extreme temperatures and rapid temperature changes, making it ideal for use in kilns and furnaces.

In terms of applications, tabular alumina is extensively utilized in the production of advanced ceramics, including structural components and refractory materials. Its hardness and mechanical strength contribute to the durability of the final products, ensuring they can withstand harsh conditions. Furthermore, tabular alumina is often used as an abrasive in various industries, providing superior performance in grinding, cutting, and polishing applications. Its versatility and reliability make it a preferred choice for manufacturers looking to enhance their products' strength and longevity.

When selecting tabular alumina for industrial use, several key factors must be considered to ensure optimal performance and efficiency. The purity of the alumina plays a significant role, as higher purity levels (typically above 99.7%) result in superior properties such as enhanced abrasion resistance and thermal stability. According to a 2022 industry report by Research and Markets, the market for high-purity alumina is expected to grow at a compound annual growth rate (CAGR) of 19% over the next five years due to increasing demand across various sectors, including ceramics and metals.

Another critical factor is the particle size distribution of the tabular alumina. Different applications require varying particle sizes to achieve desired structural properties. For instance, finer particles (below 50 microns) can enhance the packing density and mechanical strength of materials, while coarser grades can improve flow characteristics and air permeability. A comprehensive analysis from the American Ceramic Society highlights that optimizing particle size can significantly reduce material usage by up to 30%, thus lowering costs and waste for manufacturers. Ultimately, evaluating these factors will enable industries to make informed choices that align with their specific requirements and applications.

The demand for tabular alumina is expected to experience significant shifts in 2025 due to various industry trends. According to a recent market analysis by Grand View Research, the global alumina market is projected to grow at a CAGR of 6.8% from 2023 to 2028, largely driven by the increasing use of advanced ceramics and refractory materials. This rising trend indicates that industries focused on high-temperature applications, such as steel manufacturing and aerospace, will likely require higher purity and customized tabular alumina solutions.

Tip: When selecting tabular alumina, consider focusing on its granule size and purity levels. Different applications may require variations in these properties, influencing the final product's performance and efficiency.

Additionally, sustainability practices are becoming increasingly important in material selection, with a growing emphasis on eco-friendly production processes. A report from the International Aluminum Institute suggests that more manufacturers are shifting towards sustainable alumina sources, which may affect supply chains and pricing in the coming years. Companies that prioritize sustainability in their alumina sourcing will likely gain a competitive edge.

Tip: Evaluate your suppliers' sustainability initiatives and certifications. Aligning with manufacturers that adhere to eco-friendly practices can enhance your brand's reputation and meet regulatory standards.

| Application | Physical Properties | Market Demand (2025) | Key Trends |

|---|---|---|---|

| Refractories | High thermal stability, low expansion | 20,000 tons | Increased production capacity |

| Catalysts | High surface area, low porosity | 15,000 tons | Growing environmental regulations |

| Ceramics | High hardness, excellent wear resistance | 25,000 tons | Focus on lightweight materials |

| Abrasives | High durability, sharpness | 10,000 tons | Rise in precision manufacturing |

| Fiber optics | Lightweight, high refractive index | 5,000 tons | Advancements in telecommunications |

When selecting the best tabular alumina for industrial applications, it is essential to consider the specific needs of each application. Tabular alumina is prized for its high purity and exceptional stability at elevated temperatures, making it an excellent choice for industries such as refractories, ceramics, and abrasives. Innovations in manufacturing processes have led to a variety of particle sizes and morphologies available in the market, allowing for tailored solutions that maximize performance in specific applications.

Moreover, different industrial applications can significantly benefit from the unique properties of tabular alumina. For instance, its use in the production of advanced ceramics enhances mechanical strength and thermal resistance, while its application in refractory linings ensures durability in extreme conditions. Additionally, the development of customized grades of tabular alumina facilitates advancements in refractory formulations, optimizing their lifespan and efficiency in demanding environments. Therefore, understanding the nuances of tabular alumina's offerings can lead to innovative solutions that address the specific challenges faced by various industries.

This bar chart illustrates the compressive strength of various types of tabular alumina used in different industrial applications. Higher compressive strength indicates better performance in high-stress environments.

When selecting tabular alumina for industrial applications, sustainability and environmental impacts should be paramount.

Tabular alumina is a key material in various sectors, including metallurgy, ceramics, and refractories, but its production process can lead to significant carbon emissions if not managed properly.

Opting for suppliers who utilize energy-efficient technologies and sustainable practices can markedly reduce your carbon footprint.

Additionally, consider materials that are sourced from responsible suppliers, who practice sustainable mining and adhere to environmental regulations, ensuring that your choice contributes positively to the planet.

Another aspect to consider is the recyclability of the alumina you choose.

Many industries are shifting towards circular economy principles, which prioritize using materials that can be reclaimed and repurposed after their initial life cycle.

By selecting tabular alumina that can be recycled, companies not only minimize waste but also reduce the demand for virgin materials, leading to a more sustainable production cycle.

Therefore, evaluating the life cycle of the material, from extraction to disposal, is essential in making informed and environmentally friendly choices in your industrial processes.