In the world of industrial sealing solutions, the choice of materials is crucial for ensuring durability and performance. Among the various options available, Silicon Carbide Seal stands out as a preferred choice due to its remarkable hardness, thermal conductivity, and resistance to wear and corrosion. According to Dr. Emily Carter, a leading expert in material science and engineering, "Selecting the right sealing material can make all the difference in enhancing operational efficiency and longevity of machinery." Her insights underline the importance of making informed decisions when it comes to choosing seals for specific applications.

When evaluating the best Silicon Carbide Seal for your needs, it is essential to consider factors such as operating temperature, chemical exposure, and the physical demands of the environment. The unique properties of Silicon Carbide provide an exceptional balance between strength and ability to withstand harsh conditions, making it an ideal choice for sectors ranging from oil and gas to pharmaceuticals. By understanding the various applications and characteristics of Silicon Carbide Seals, businesses can significantly improve their sealing performance and reduce downtime. As industries continue to evolve, so too does the need for advanced sealing technologies that ensure reliability and efficiency.

Silicon carbide (SiC) seals have gained significant attention due to their unique properties, making them ideal for various applications. Understanding the different materials and their characteristics is crucial when selecting the best seal for your specific needs. Silicon carbide is known for its high thermal stability, excellent corrosion resistance, and extraordinary hardness, allowing it to perform well in harsh environments. This makes it a popular choice in industries such as automotive, aerospace, and chemical processing.

Tips: When choosing a silicon carbide seal, consider the operating temperature and the chemical environment. High temperatures can affect the durability of the seal, while certain chemicals may cause degradation. Additionally, ensure that the seal is compatible with the specific media it will be exposed to. This can help in prolonging the life of the seal and maintaining optimal performance.

Another important property of silicon carbide is its ability to withstand high pressure variations, making it suitable for dynamic applications where movement is prevalent. The fine microstructure of SiC also contributes to low friction and wear resistance, which is essential in reducing maintenance costs over time. Always evaluate the mechanical properties required for your application to ensure you select the most appropriate silicon carbide seal for your system.

| Material Type | Hardness (Mohs) | Temperature Resistance (°C) | Chemical Resistance | Applications |

|---|---|---|---|---|

| Silicon Carbide (SiC) | 9 | 1600 | Excellent | Aerospace, Oil & Gas |

| Reaction Bonded SiC | 8.5 | 1400 | Very Good | Automotive, Chemical Processing |

| Sintered SiC | 9 | 1800 | Excellent | Pumping Systems, Aerospace |

| Silicon Nitride (Si3N4) | 8 | 1200 | Good | High-performance Seals, Bearings |

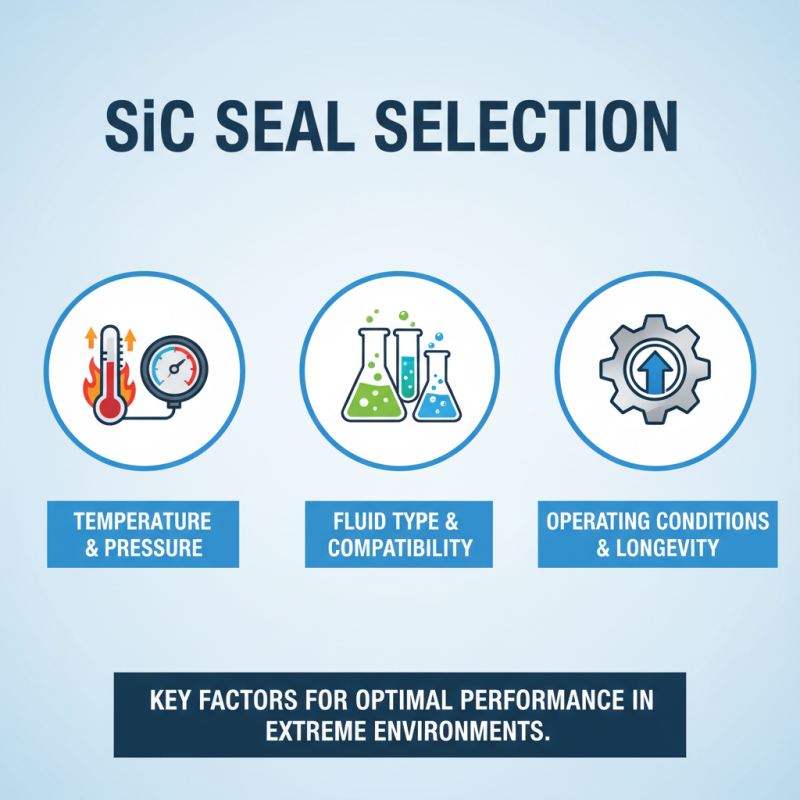

When selecting silicon carbide seals for specific applications, it is essential to consider several key factors that influence their performance and longevity. First, one must evaluate the operating conditions, including temperature, pressure, and the type of fluids being sealed. Silicon carbide seals are known for their high thermal resistance and chemical stability, which makes them suitable for applications that involve extreme environments. Understanding these parameters will help in choosing a seal that can withstand the operational demands without degrading over time.

Another critical factor is the mechanical properties of the silicon carbide material itself. Different grades of silicon carbide may offer varying degrees of hardness, toughness, and wear resistance. An application involving abrasive materials, for instance, may require a seal with superior hardness to prevent premature wear. Additionally, the surface finish and geometrical design of the seal can also significantly affect its sealing efficacy and installation ease. By thoroughly assessing these factors, engineers can ensure the selected silicon carbide seal will perform reliably and efficiently for its intended application.

When selecting a silicon carbide seal for specific applications, two critical performance metrics must be evaluated: wear resistance and temperature ratings. Wear resistance is essential as it determines how well the seal can withstand prolonged exposure to mechanical stress and abrasive environments. A higher wear resistance typically results in longer seal life, reducing maintenance costs and downtime. Additionally, assessing the material's ability to resist wear under various conditions—such as fluid type and concentration—can provide valuable insights into its performance.

Temperature ratings are equally important as many applications require seals to operate under extreme thermal conditions. Silicon carbide seals are known for their ability to maintain integrity at elevated temperatures, making them suitable for high-performance environments. It is vital to review the specific temperature ratings provided by the manufacturer and ensure they align with the operating conditions of your application. Understanding both the minimum and maximum temperature thresholds helps in selecting the right seal for optimal performance.

Tips: When evaluating seals, consider the specific environmental factors, such as chemical exposure and pressure fluctuations, which can impact wear resistance. Also, consult with suppliers to understand the test conditions under which the temperature ratings were determined, as real-world applications can vary significantly. Remember to regularly monitor the performance of seals in operation to identify potential issues before they lead to seal failure.

When budgeting for silicon carbide seals in engineering projects, a comprehensive cost analysis is essential. Silicon carbide is renowned for its outstanding durability and resistance to abrasion, corrosion, and high temperatures, making it a popular choice in various applications. However, the initial costs can be significantly higher compared to traditional sealing materials. Therefore, it is crucial to evaluate both the upfront expenses and the long-term savings that come with choosing silicon carbide seals. These seals often result in reduced maintenance and replacement frequencies, which can lead to lower operational costs over time.

In addition to the material cost, engineers should consider the specific application requirements and the potential impact of these seals on system performance. Factors such as load conditions, fluid compatibility, and environmental factors play a vital role in determining the most suitable silicon carbide seal for a project.

It may also be beneficial to conduct a life-cycle cost analysis, taking into account not just the purchase price but also installation, maintenance, and potential downtime. By assessing these elements holistically, project managers can optimize their budgets and ensure that they are making sound financial decisions while harnessing the benefits of silicon carbide technology.

When it comes to maintaining silicon carbide seals, proper care and attention to detail are essential for ensuring their longevity. Regular inspections are critical; these should focus on identifying signs of wear, such as surface scratches or discoloration, which can indicate potential failure points. Keeping the surrounding environment clean and free from contaminants can also extend the lifespan of these seals, as foreign particles can lead to increased friction and accelerated wear.

Another important maintenance consideration is the lubrication of silicon carbide seals. While these seals typically have self-lubricating properties, ensuring that the appropriate lubricants are used can significantly reduce wear and tear. Regularly checking lubrication levels and types can help to maintain optimal performance. Furthermore, operating conditions should be monitored to avoid extreme temperature fluctuations and pressures, which could adversely affect the integrity of the seals. By following these maintenance guidelines, users can enhance the reliability and durability of silicon carbide seals within their applications.