In the world of advanced materials, Silicon Carbide Tubes stand out as a crucial innovation. Dr. Emily Chen, an expert in high-performance ceramics, emphasizes, "Silicon Carbide Tubes offer unmatched durability and thermal stability." This statement reflects the growing recognition of their applications in high-temperature environments.

Silicon Carbide Tubes are known for their strength and resistance to thermal shock. Industries like aerospace and electronics often rely on these tubes. They can withstand extreme conditions where traditional materials fail. However, the high cost and manufacturing complexity can be challenging barriers. Not every application may justify the investment in Silicon Carbide Tubes.

Despite potential drawbacks, the benefits can outweigh the shortcomings in many cases. The unique properties of Silicon Carbide Tubes make them ideal for specific tasks, enhancing efficiency and performance. For companies aiming to innovate, exploring Silicon Carbide Tubes is worthwhile, even if the initial journey may require a bit of reflection and adjustment.

Silicon carbide tubes are gaining traction in high-temperature applications. These tubes can withstand extreme temperatures, often exceeding 1,600°C. This ability makes them ideal for industries like aerospace and semiconductor manufacturing. According to a recent report by the International Journal of Thermal Sciences, silicon carbide's thermal conductivity is significantly higher than that of traditional materials. This means better heat dissipation, crucial in high-performance environments.

The mechanical strength of silicon carbide tubes is noteworthy. They exhibit low thermal expansion, reducing the risk of cracking under thermal stress. A study conducted by the Materials Research Society reveals that these tubes maintain structural integrity under fluctuating temperatures. In contrast, other materials tend to warp or fail more quickly, leading to costly downtime.

Their resistance to corrosion is another advantage. Silicon carbide tubes resist oxidation and chemical attack, extending service life in hostile environments. However, the cost of silicon carbide can be higher than alternatives. This might cause hesitation for some companies. Careful consideration of the long-term benefits can outweigh the initial investment. The choice of silicon carbide should align with the specific needs of each application.

Silicon carbide (SiC) tubes are increasingly popular due to their unique properties. They offer excellent thermal stability and impressive hardness. In applications requiring high temperature and corrosion resistance, SiC often outperforms traditional materials like metals and ceramics. A study by the International Journal of Advanced Manufacturing Technology found that SiC withstands temperatures up to 1,600°C.

When comparing SiC tubes to alumina or stainless steel, differences are clear. For instance, alumina has a maximum service temperature of around 1,200°C. This limitation may hinder performance in extreme environments. On the other hand, stainless steel can suffer from oxidation at elevated temperatures. A report from the American Society for Testing and Materials highlights that SiC maintains structural integrity better under thermal stress, making it a more reliable choice.

Despite these advantages, SiC tubes are not without challenges. They can be more brittle compared to metals, leading to issues in applications with mechanical shock. The manufacturing process for SiC also tends to be more complex and costly. This could deter some industries from choosing SiC initially. However, when weighed against performance benefits, the investment may be justified.

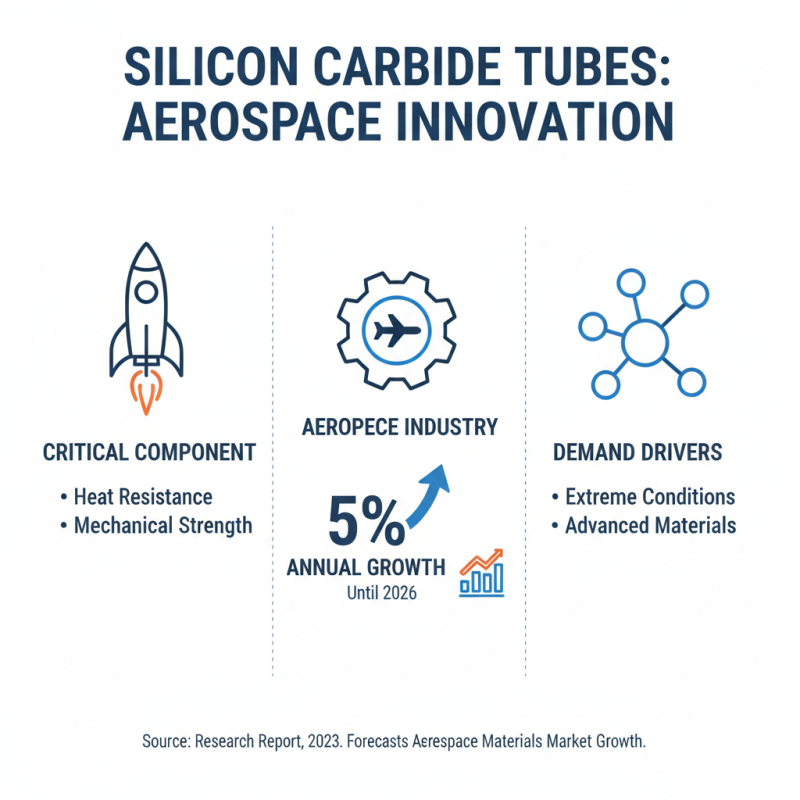

Silicon carbide tubes have emerged as an essential component in various industries. The aerospace sector, for example, relies on them for their heat resistance and mechanical strength. According to a recent research report, the aerospace materials market is projected to grow by 5% annually until 2026. This growth reflects the increasing demand for advanced materials that can withstand extreme conditions.

In the automotive industry, silicon carbide tubes enhance fuel efficiency and reduce emissions. A study indicated that replacing traditional components with silicon carbide could increase efficiency by up to 40%. This shift not only aids environmental goals but also boosts overall performance.

However, despite their benefits, some challenges persist. Cost remains a concern for smaller enterprises looking to adopt these technologies. Additionally, the manufacturing process of silicon carbide can be complex, leading to variability in product quality. These issues require careful consideration as industries proceed with implementation.

When selecting silicon carbide tubes, several key factors come into play. These tubes offer high thermal conductivity, making them ideal for extreme environments. A report by the DSI Group notes that silicon carbide can withstand temperatures up to 1,600°C, which is crucial for industries like aerospace and semiconductor manufacturing. In addition, their low thermal expansion coefficient minimizes risk of damage under varying heat conditions.

Durability is another important consideration. Silicon carbide tubes exhibit exceptional resistance to wear and corrosion. The Materials Science Research report highlights that these tubes have a hardness rating of 9 on the Mohs scale, surpassing many metals. This means they can endure abrasive materials in various applications. However, it’s essential to evaluate the specific needs of your project. The cost can be a limiting factor; opting for these tubes may require a larger initial investment.

Lastly, compatibility is vital. Certain chemicals can degrade silicon carbide. Understanding the operational environment is crucial. Not all silicon carbide formulations behave the same under different conditions. This can lead to unexpected challenges. Taking the time to assess these factors ensures a better selection and performance of silicon carbide tubes in your applications.

This chart illustrates the various applications of Silicon Carbide Tubes based on industry usage percentage. The data shows the growing popularity of these tubes across different sectors due to their unique properties.

Silicon carbide (SiC) tubes are gaining traction across various industries due to their exceptional properties. This material withstands extreme temperatures and exhibits robust chemical resistance. As industries seek more efficient materials, SiC tubes become a prime choice. The versatility in manufacturing processes contributes to their expanding applications. These tubes are now being utilized in demanding environments, such as in aerospace and automotive sectors.

Looking ahead, the evolution of SiC tube technology will likely focus on enhancing their mechanical strength and thermal conductivity. Research is ongoing to explore innovative composites combining SiC with other materials. Additionally, advancements in fabrication techniques can lead to thinner, lighter tubes with even greater performance capabilities. There is a strong potential for their application in renewable energy technologies, such as solar power systems.

However, challenges remain. The cost of SiC production can be high, limiting widespread adoption. Companies must find ways to balance performance with affordability. Sustainability in manufacturing processes also needs further exploration. With the right investments and innovations, silicon carbide tubes could see significant advancements in both technology and applications.