In the realm of surface protection, ceramic coating for aluminum is rapidly gaining recognition as a game-changer. Experts like Dr. Sarah Thompson, a leading authority in advanced protective coatings, assert, “Ceramic coatings enhance the durability and aesthetic appeal of aluminum surfaces, while providing an unparalleled shield against environmental aggressors.” This innovative technology forms a resilient barrier that not only safeguards aluminum from corrosion and wear but also is easier to maintain compared to traditional coatings.

As industries increasingly turn to aluminum for its lightweight and versatile properties, ensuring its longevity and maintaining an appealing finish become paramount. Ceramic coatings are engineered to match the unique challenges associated with aluminum surfaces, delivering superior performance under various conditions. With their hydrophobic properties, these coatings repel water and contaminants, ensuring that the inherent beauty of aluminum remains intact over time.

Ultimately, embracing ceramic coating for aluminum is not merely a cosmetic decision; it is a strategic investment in the future of aluminum products. As the demand for durable and aesthetically pleasing materials rises, understanding the benefits of ceramic coatings will empower manufacturers and consumers alike to make informed choices that enhance the lifespan and functionality of aluminum surfaces.

Ceramic coating offers a multitude of benefits for aluminum surfaces, making it an optimal choice for both aesthetics and protection. One of the primary advantages is its remarkable durability. Unlike traditional paint or sealants, ceramic coatings provide a hard, protective layer that is resistant to scratches, chips, and harsh environmental factors. This enhanced durability not only prolongs the lifespan of aluminum surfaces but also ensures they maintain their sparkle and appearance over time, even when exposed to UV rays and other degrading elements.

Moreover, ceramic coatings are hydrophobic, meaning they repel water and contaminants. This property helps to keep aluminum surfaces cleaner, reducing the need for frequent maintenance and cleaning. It also prevents the buildup of dirt, grime, and other environmental pollutants that can lead to corrosion or deterioration. By facilitating easy cleaning and reducing the frequency of upkeep, ceramic coatings effectively optimize the longevity and functionality of aluminum surfaces, making them a wise investment for both residential and commercial applications.

Ceramic coatings are advanced protective solutions composed primarily of inorganic materials, which are engineered to bond closely with aluminum surfaces. These coatings generally consist of silica (SiO2) and various ceramic compounds that offer exceptional durability and resistance to environmental factors. When applied, the composition forms a hard, resilient shield that can withstand extreme temperatures, chemical exposure, and physical abrasions, making it ideal for high-performance applications on aluminum.

The unique properties of ceramic coatings stem from their molecular structure. The tightly packed arrangement of particles in the coating provides a dense barrier, enhancing the overall strength and longevity of aluminum surfaces. Furthermore, these coatings often possess hydrophobic qualities, which help repel water and contaminants, reducing the frequency of cleaning and maintenance required. This characteristic not only preserves the appearance of aluminum but also aids in preventing corrosion, ensuring that the underlying metal remains protected over time.

When comparing ceramic coating to traditional finishes for aluminum surfaces, several key differences highlight the advantages of modern ceramic technologies. Traditional finishes, such as paints and powder coatings, offer a level of protection and aesthetic appeal but can fall short in terms of durability and longevity. These finishes are susceptible to chipping, scratching, and fading over time, often requiring regular maintenance and reapplication to maintain their appearance and effectiveness.

In contrast, ceramic coatings create a robust, durable layer that chemically bonds to the aluminum surface. This bond results in superior resistance to scratches, chemicals, and UV rays, ensuring that the surface remains intact and visually appealing for extended periods. Additionally, ceramic coatings are hydrophobic, meaning they repel water and contaminants, making cleaning significantly easier and reducing the frequency of maintenance needed. As a result, the lifetime cost of ownership can be lower when opting for ceramic coatings despite higher initial installation costs. These characteristics make ceramic coatings an increasingly popular choice for surfaces that require both protection and aesthetic enhancement.

| Feature | Ceramic Coating | Traditional Finishes |

|---|---|---|

| Durability | Highly durable, resistant to scratches and chips | Less durable; prone to scratches and chipping |

| Chemical Resistance | Excellent resistance to chemicals and environmental factors | Moderate resistance; may degrade under harsh chemicals |

| Maintenance | Low maintenance; easy to clean | Higher maintenance; requires frequent cleaning and polishing |

| Application Process | Requires professional application for best results | Often DIY friendly; can be applied at home |

| Cost | Higher initial investment but cost-effective over time | Lower initial cost but may require more frequent reapplication |

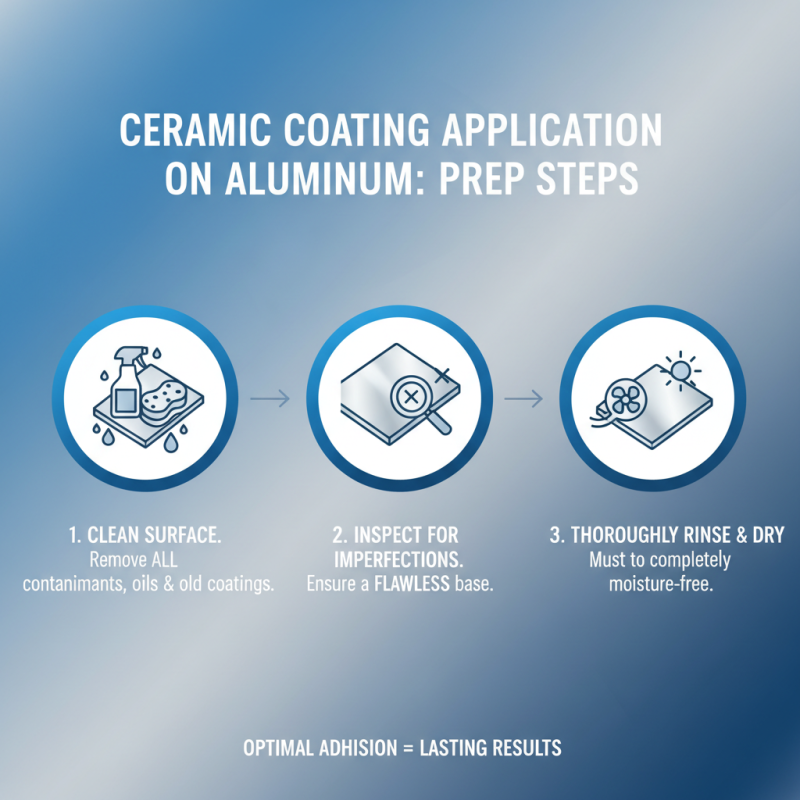

The application process of ceramic coating on aluminum surfaces requires careful preparation and attention to detail to ensure optimal results. First, it is essential to thoroughly clean the aluminum surface to remove any contaminants, oils, or existing coatings. This can be achieved using a degreaser and a suitable cleaning solution, followed by thorough rinsing and drying. Ensuring that the surface is free from imperfections is critical, as any dirt or residues can affect the adhesion of the ceramic coating.

Once the surface is prepared, the ceramic coating can be applied. This usually involves using a foam applicator or a microfiber cloth to apply the coating evenly across the aluminum surface. It's important to work in small sections to ensure that the product is adequately spread and to prevent any premature curing. After application, the coating should be allowed to cure as per the manufacturer's instructions, usually requiring a few hours to fully bond with the aluminum. Following the curing period, a topcoat or a finishing polish may be applied to enhance the shine and durability of the finish. Proper curing and handling of the coated surface will result in improved resistance to scratches, chemicals, and environmental factors.

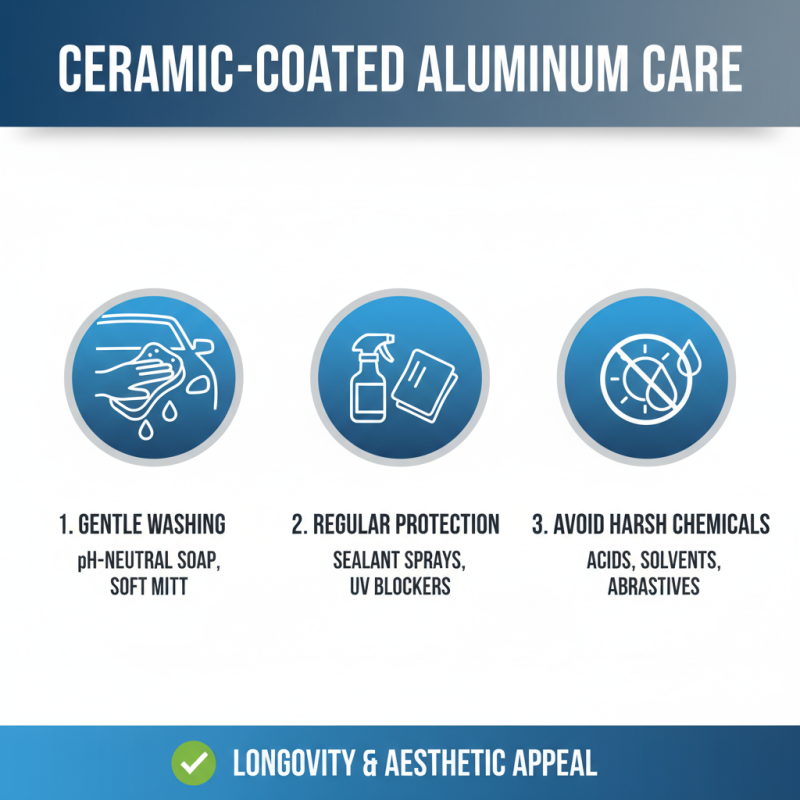

Maintaining ceramic-coated aluminum surfaces is essential to ensure their longevity and aesthetic appeal. Ceramic coatings provide a durable layer that protects against scratches, UV rays, and environmental damage. However, even the strongest coatings require proper care to maintain their effectiveness.

One of the best practices is regular washing. Use a pH-neutral soap and a soft cloth to gently clean the surface. Avoid harsh chemicals or abrasive tools that can damage the coating. When washing, always work from the top down to prevent dirt from settling on cleaned areas. Additionally, drying the surface with a microfiber towel can prevent water spots and streaks, ensuring a flawless appearance.

Another key maintenance tip is to apply a maintenance spray or detailer designed for ceramic coatings every few months. This helps to replenish the hydrophobic properties of the coating, enhancing its ability to repel water and dirt. Keep an eye on the surface for signs of wear, such as decreased water beading, as this may indicate the need for reapplication of the ceramic coating to retain its protective qualities. Regular upkeep will ensure that your ceramic-coated aluminum surfaces remain in top condition for years to come.