Aluminium Oxynitride, a compound of aluminum, oxygen, and nitrogen, possesses unique properties. It offers great strength and durability, making it suitable for various applications. This material is also known for its exceptional transparency, which rivals glass.

In the defense industry, Aluminium Oxynitride is used for its ballistic protection. Its lightweight nature allows for greater mobility. However, the cost of production remains a concern. Many industries are exploring its potential, yet challenges in manufacturing scale persist.

Applications extend beyond defense. The optical industry is interested in its use for advanced lenses and windows. Despite its advantages, Aluminium Oxynitride is not yet widely adopted. Research continues to identify methods that make it more accessible and affordable. The future may hold greater promise for this remarkable material.

Aluminium oxynitride, a unique ceramic material, exhibits remarkable properties. This compound is known for its high strength and low weight. It has a high hardness level, making it resistant to scratches and damage. Additionally, aluminium oxynitride boasts a high thermal stability, allowing it to maintain performance in extreme conditions. Its transparency in the visible spectrum is another noteworthy feature, enabling its use in optical applications.

In various applications, aluminium oxynitride shines. It is utilized in military armor, providing protection without excessive weight. Also, it finds use in aerospace components, where strength-to-weight ratio is crucial. In electronic devices, its insulating properties are beneficial, helping in heat resistance. However, some challenges remain. The production process can be complicated and costly. Quality control during manufacturing is essential, as slight variations can affect performance. Users need to consider these factors when choosing this material for specific applications.

Aluminium oxynitride, often known as ALON, displays unique optical characteristics that make it a fascinating material. Its transparency across various wavelengths, including visible light, infrared, and even some ultraviolet, sets it apart. For example, research indicates that ALON has a greater transmission rate than sapphire in the near-infrared spectrum. This feature promotes its use in advanced optical applications.

In military optics, ALON is gaining traction. It offers superior strength and scratch resistance. These qualities allow it to withstand harsh environments. However, the material isn't without challenges. Its production can be complex and costly. A report from the Materials Science and Engineering department highlighted a significant disparity in production costs compared to traditional optical materials.

Moreover, ALON's performance at high temperatures is another area to consider. The material remains stable at temperatures up to 1000 degrees Celsius, which is impressive. Yet, achieving this stability often requires precise control over the manufacturing process. Any deviation may lead to defects, hindering its optical performance. This reflects a need for ongoing improvement in production techniques to fully harness ALON's potential.

| Property | Description | Applications |

|---|---|---|

| High Hardness | Aluminium oxynitride is extremely hard, making it suitable for protective applications. | Armor, aerospace components |

| Transparency | It exhibits optical transparency in the visible and infrared spectrum. | Optical components, sensors |

| Low Density | Lightweight compared to traditional ceramics. | Aerospace, military applications |

| Chemical Resistance | Resistant to a wide range of chemicals and harsh environments. | Chemical processing, laboratory equipment |

| Thermal Stability | Maintains properties at high temperatures. | High-temperature applications, furnace windows |

Aluminium oxynitride, often referred to as Alumina, is known for its unique properties. Its mechanical strength is remarkable. This material can withstand significant stress without breaking. Many engineers choose aluminium oxynitride for high-performance applications. Its durability is apparent in extreme conditions.

The hardness of aluminium oxynitride is another notable feature. It resists scratches and abrasions effectively. This adds to its long lifespan in various applications. From armor to optics, its use is widespread. However, some may question its cost compared to traditional materials.

When considering applications, the effectiveness of aluminium oxynitride can vary. In some environments, its performance may not meet expectations. Users must assess whether it is suitable for their needs. Despite challenges, its potential in innovative design remains bright. Understanding its limitations is key to future advancements.

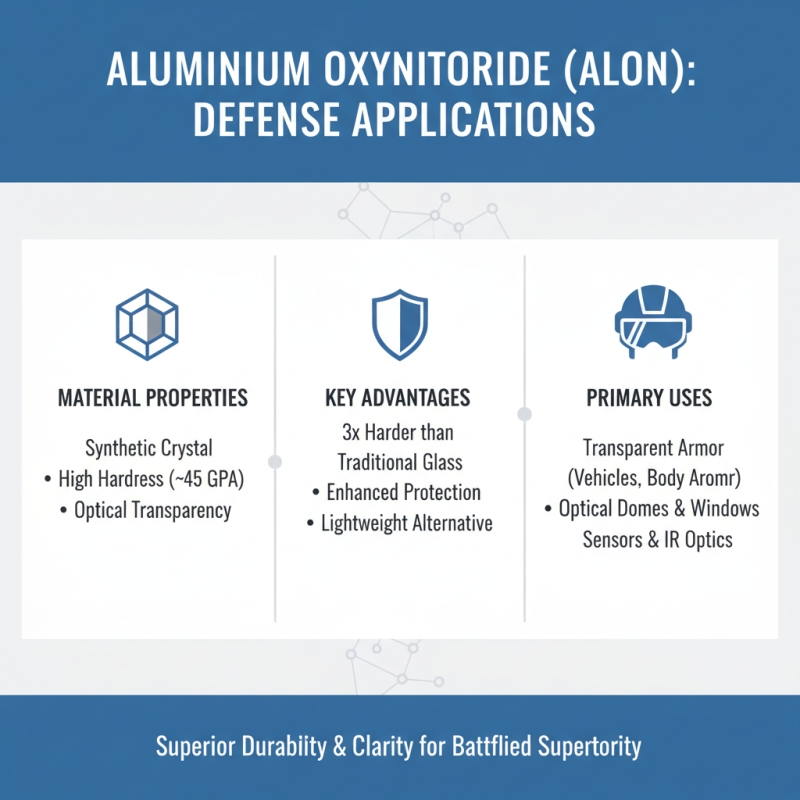

Aluminium oxynitride, often referred to as ALON, demonstrates exceptional properties that make it ideal for defense applications. This synthetic crystal boasts high hardness and good transparency, making it useful in armor and optical components. ALON is about three times harder than traditional glass, which enhances its protective capabilities. Reports suggest that its hardness reaches around 45 GPa, a significant advantage in battlefield scenarios.

In armored applications, ALON provides weight benefits compared to traditional materials. It offers a lower weight-to-strength ratio while maintaining outstanding ballistic resistance. Some studies indicate that ALON can withstand impacts up to 60% more effectively than conventional ceramics. This quality reduces the load on soldiers, allowing for more agility during missions. The optical components benefit from ALON's transparency across a wide wavelength range. This feature enables advanced targeting and surveillance systems, crucial for situational awareness.

However, the production costs of ALON can be higher than that of other materials. The complexity of manufacturing processes poses challenges for large-scale adoption. Additionally, while its properties are remarkable, ongoing research is needed to fully understand the long-term durability of ALON in extreme conditions. Balancing cost, performance, and production feasibility remains an area for improvement in this promising material for defense applications.

Aluminium oxynitride (ALON) is gaining traction in the electronics and aerospace industries. Its properties, such as high strength and transparency, make it an ideal choice for various applications. In electronics, ALON can be used in advanced display technologies. Its durability allows for lightweight, protective screens in mobile devices. Reports indicate that the market for alumina and its derivatives, including ALON, is expected to grow significantly, reaching approximately $59 billion by 2025.

In aerospace, ALON's thermal stability is particularly beneficial. The material can withstand extreme conditions. It may be used in cockpit displays and sensor windows. A leading aerospace report suggests a 15% growth rate for ceramic materials, underscoring the demand for ALON. However, integrating ALON into existing manufacturing processes poses challenges. The material's brittle nature can lead to issues during production.

Innovation is key to overcoming these hurdles. Research is needed to improve production techniques and cost efficiency. Understanding ALON's full potential will require addressing these challenges. There is still much to learn about the long-term performance of ALON in demanding applications. As industries evolve, aluminium oxynitride could play a crucial role, but its integration needs careful consideration.