In today's industrial landscape, choosing the right materials for high temperature applications is crucial. Alumina Tubing stands out as a preferred option due to its exceptional thermal stability. Dr. Emily Chen, an expert in materials science, states, “Alumina Tubing provides unmatched performance under extreme heat.” This highlights its importance in various fields, including aerospace and electronics.

Alumina Tubing is known for its ability to withstand temperatures exceeding 1,600 degrees Celsius. Its lightweight nature combined with high strength makes it ideal for numerous applications. Many industries rely on this material to ensure durability and efficiency. However, not all applications fully leverage the potential of Alumina Tubing.

Despite its benefits, decision-makers often overlook Alumina Tubing for alternatives. This can lead to inefficiencies and increased costs. A deeper understanding of its advantages is necessary for proper implementation. Exploring the full capabilities of Alumina Tubing could revolutionize high temperature applications. Investing time in research and discussions is essential for optimizing material use.

Alumina tubing offers remarkable advantages for high-temperature applications. Its ability to withstand extreme temperatures makes it an ideal choice for industries like aerospace and ceramics. At temperatures over 1500°C, alumina maintains structural integrity. This resilience ensures safety in critical environments.

Additionally, alumina tubing exhibits excellent thermal insulation properties. It reduces heat transfer, protecting sensitive components. Many users appreciate this capability, as it helps maintain operational efficiency. The low thermal conductivity ensures that systems remain stable under stress. However, some users have encountered challenges in handling and installation.

Another benefit of alumina is its chemical resistance. It can endure corrosive substances without degrading. This property is vital in processes involving reactive materials. Even so, some might find it brittle under specific conditions. Careful handling is essential to prevent breakage. Overall, alumina tubing remains a strong contender for high-temperature applications due to its unique properties that meet industry demands.

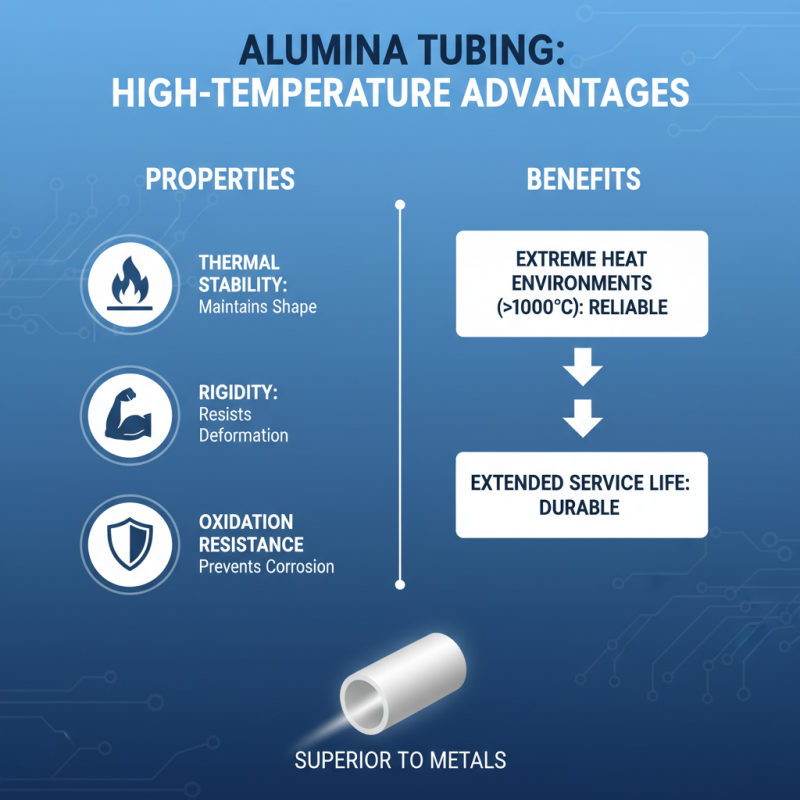

Alumina tubing is a great choice for high-temperature applications. Its unique properties make it stand out. One key feature is its excellent thermal stability. It can withstand extreme temperatures without degrading. This means it maintains its strength and shape even in harsh environments.

Another important property is its chemical resistance. Alumina does not react easily with most substances. This makes it ideal for high-temperature chemical processes. It shows minimal wear over time, which is crucial in demanding situations. Users appreciate that it can be used in many industrial applications without failing.

Tips: When selecting alumina tubing, consider the specific temperature range. Ensure it aligns with your application requirements. Also, check compatibility with other materials. It’s essential for successful integration into systems. Remember, testing is vital. Conduct trials to identify any weaknesses in your setup. Even the best materials need evaluation in real-world conditions.

Alumina tubing has gained popularity across various industries due to its remarkable properties. In the aerospace sector, it is used for components that require exceptional heat resistance. The extreme temperatures in jet engines demand materials that can withstand harsh conditions. Alumina's ability to maintain structural integrity makes it a prime choice.

The automotive industry also benefits from alumina tubing. It is often used in thermal management systems. Heat shields crafted from alumina help protect sensitive components. This ensures that vehicles perform optimally under stressful conditions. However, designing these parts can be challenging. Engineers must consider both heat resistance and weight.

In the electronics field, alumina tubing serves as an insulator in high-temperature applications. It provides reliable protection for critical components in circuits. The need for efficiency drives innovation, pushing manufacturers to refine designs continuously. There is still room for improvement in the fabrication process, particularly regarding precision and quality assurance.

Alumina tubing is often favored for high-temperature applications due to its unique properties. Unlike metals, which can deform under extreme heat, alumina maintains its shape. This stability is crucial in environments that exceed typical thermal limits. The ability of alumina to resist oxidation also makes it a superior choice. While metals may corrode, alumina stays intact, enhancing longevity.

In comparison, silicon carbide offers some advantages but can be brittle. At elevated temperatures, it might fracture under stress. On the other hand, polymers simply cannot withstand high heat levels without degrading. They lose their structural integrity quickly, which is a significant drawback.

Though alumina has clear benefits, it’s not without its challenges. It can be more expensive than alternative materials. Transporting and handling alumina tubing requires care to prevent damage. Additionally, while it performs well under high temperatures, its efficiency can diminish if not properly designed for specific applications. This balance of pros and cons is essential to consider when selecting materials for high-temperature uses.

When considering alumina tubing for high temperature applications, several challenges arise. These tubes can withstand extreme heat, but they are not impervious to cracking. High thermal shock can lead to structural failure. Careful handling during installation is crucial. Any abrupt temperature change affects stability.

Another key consideration is the brittleness of alumina. It offers excellent insulation but is more fragile than metals. This fragility complicates transportation and installation. Users must implement protective measures. Inadequate support can cause bending or breakage. Engineers should evaluate the weight and load conditions.

Lastly, alumina tubing's surface can become contaminated. High temperatures can change its chemical properties. This may undermine performance. Routine inspection is vital. Users should be aware of potential degradation over time. Using alumina requires mindful planning and continuous assessment.