Alumina plates are increasingly essential in various industries. These materials offer excellent durability and resistance to wear. According to a recent market analysis, the global demand for alumina plates is projected to grow at a CAGR of 5.2% through 2026. This growth is driven by applications in electronics, aerospace, and biomedical fields.

The versatility of alumina plates is remarkable. They can withstand high temperatures and harsh environments. Industries use them for insulation, substrates, and structural components. Some reports highlight their efficiency in reducing production costs. Yet, purchasing the right alumina plate can be challenging. Buyers must consider factors like thickness, size, and purity levels.

In a competitive market, not all suppliers guarantee quality. Understanding the specific needs of your application is crucial. Additionally, misjudging the required specifications could lead to inefficiencies. Despite the challenges, the benefits of using alumina plates are undeniable. Investing time in research can pay off significantly in the long run.

Alumina plates have become essential in various industries. They are made from aluminum oxide, which offers impressive strength and durability. These plates can withstand extreme temperatures and offer excellent wear resistance. As a result, they are ideal for applications like cutting tools, electrical insulators, and structural components.

In the medical field, alumina plates are gaining traction. They are used in dental applications and orthopedic implants due to their biocompatibility. However, there is still room for improvement in the manufacturing process. Variations in composition can affect the final product's properties. This inconsistency can lead to challenges in specific applications.

In electronics, alumina plates serve as substrates for circuit boards. Their insulating properties help in reducing signal interference. Still, they can be brittle, which raises concerns during installation. It's crucial to balance strength and brittleness to meet industry standards. Overall, understanding the applications and potential drawbacks of alumina plates is vital for making informed choices.

Alumina plates are increasingly pivotal in various industries, notably due to their remarkable thermal stability and mechanical strength. According to recent data, alumina can withstand temperatures exceeding 1,600 degrees Celsius. This feature makes it ideal for applications in aerospace and manufacturing. Additionally, alumina plates possess excellent wear resistance, essential for components subjected to significant friction. Industries like automotive and mining benefit from this durability.

The chemical resistance of alumina is equally noteworthy. Withstanding aggressive chemicals, alumina plates are often utilized in pharmaceutical settings, where purity and stability are critical. Reports indicate that alumina has a very low porosity, contributing to its effectiveness in such applications. However, the production of alumina plates can be energy-intensive. Some manufacturers are exploring more sustainable methods, reflecting an industry shift toward environmental responsibility.

Using alumina plates can also pose challenges. The rigid nature of the material means it can be difficult to machine accurately. Proper training and tools are essential for manufacturers to avoid costly errors. Furthermore, while the initial cost might be high, the long-term benefits through reduced maintenance expenses are significant. Thus, the focus should be on optimizing the lifecycle of alumina products to fully leverage their advantages.

When considering the purchase of alumina plates, there are several key factors to keep in mind. The quality of the alumina material is paramount. High-purity alumina, such as 99.5% and above, offers superior chemical resistance and mechanical strength. According to industry reports, plates made from high-purity alumina can withstand temperatures up to 1600°C, making them suitable for demanding applications.

Another crucial factor is the thickness of the plate. Depending on the application, thicker plates excel in structural support, while thinner options may be adequate for thermal protection. Experts have noted that a thickness of 10mm often strikes the right balance between durability and weight. However, it’s vital to assess specific needs carefully. Sometimes, a thicker plate may hinder performance in other ways, such as increased weight limiting design flexibility.

Also, consider the surface finish of the plates. A smoother surface can reduce friction in certain applications, while a rough texture may enhance adhesion. According to recent surveys, about 30% of buyers overlook this detail, potentially leading to suboptimal results. Reflecting on these factors can help ensure that the chosen alumina plates meet both performance standards and budget requirements effectively.

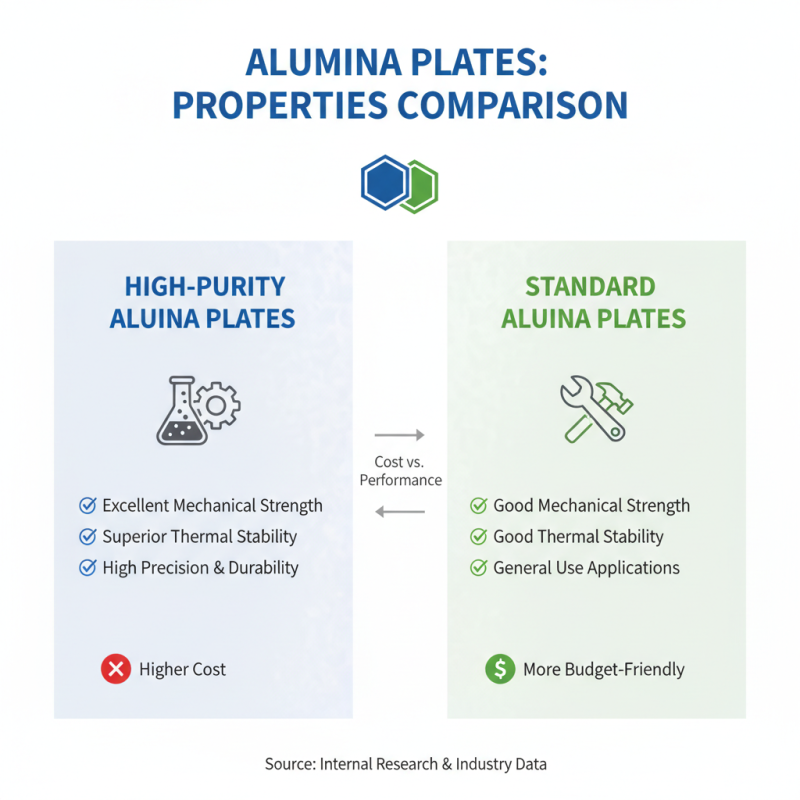

When comparing different types of alumina plates, it's essential to consider their unique properties. High-purity alumina plates are known for their excellent mechanical strength and thermal stability. They are often used in applications that require high precision and durability. However, these plates can come with a higher price tag, which might not fit every budget.

Another common variety is the low-cost alumina plate. These plates are more affordable, making them a popular choice for less demanding applications. Nevertheless, they may not perform as well under extreme conditions. Users must weigh cost against performance. A less expensive option might save money now but could lead to issues later.

Finally, it's crucial to think about the thickness and size options available. Thicker plates generally provide better resistance to wear and impact. Yet, they can be heavier and cumbersome to handle. Every buyer should evaluate their specific needs. They might find that a thinner plate is more suitable for their projects. Attention to detail in these choices can greatly influence results.

Caring for alumina plates is essential to maintain their performance and longevity. These plates are known for their high strength and resistance to wear. However, neglect can lead to damage or reduced effectiveness. Regular cleaning is crucial. Use a soft cloth to wipe off any dust or residues. Avoid harsh chemicals that may scratch or corrode the surface.

Tip: Store alumina plates in a dry place. Humidity can weaken their structure. Ensure they are placed on a flat, stable surface to prevent unintended stress or warping. Even minor adjustments in temperature can affect their stability.

Inspecting the plates periodically is also necessary. Look for any signs of cracks or chips. These can lead to more significant issues if ignored. If you notice damage, consider whether the plate can be repaired or needs replacing. This reflection can save you money and maintain efficiency. Lastly, always handle alumina plates with care. Dropping them can cause irreversible damage, so be mindful during storage and transport.